Grow Room HVAC Guide

Selecting the right HVAC system type for a grow room is crucial for the success of the crop. However, with so many options available, it can be tricky to know how to manage these factors effectively.

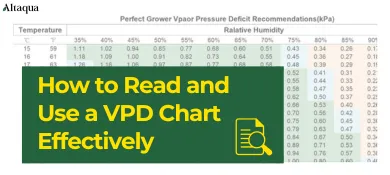

Our grow room hvac guide breaks down essential topics like temperature and humidity control, system comparisons, and how environmental factors impact plant growth. Follow our blogs for more insights to help you choose the perfect HVAC system for your needs.