Cannabis HVAC: Why Standard HVAC Systems Fail in Commercial Grow Rooms

Updated: Dec. 26 ,2025 · 6 min read

Abstract: Commercial cannabis cultivation places unique demands on climate control that traditional HVAC systems were never designed to handle. This article explores why standard HVAC architectures fail in grow rooms, when upgrading becomes unavoidable, and how purpose-built cannabis HVAC systems deliver stable VPD, lower energy costs, and consistent results at commercial scale.

If you’re searching for cannabis HVAC, chances are you’ve already run into the limits of standard HVAC setups.

In commercial cannabis grow rooms, temperature and humidity don’t drift slowly—they spike, crash, and fight each other around the clock. What looks stable during the day often breaks down at night, when lights go off, transpiration drops, and humidity surges.

Many growers start with conventional air conditioning paired with standalone dehumidifiers. It works—until scale, plant density, and 24/7 operation expose the cracks. Systems begin short-cycling. VPD drifts out of range. Energy costs climb while environmental stability becomes harder to maintain, not easier.

This is where cannabis HVAC stops being a buzzword and becomes a necessity. Unlike comfort cooling designed for people, cannabis HVAC systems are engineered around latent moisture loads, rapid environmental swings, and the constant demands of commercial cultivation. They’re built to control temperature and humidity independently, maintain stable VPD, and operate efficiently across veg, flower, and dry rooms—day and night.

In this article, we’ll break down why traditional HVAC architectures struggle in cannabis facilities, when upgrading becomes unavoidable, and how purpose-built cannabis HVAC systems support consistent yields, lower energy costs, and long-term operational stability.

When Do Growers Actually Need a Cannabis HVAC System?

Most growers don’t start out looking for a cannabis HVAC system. They arrive here after realizing that their current setup—usually standard air conditioning paired with standalone dehumidifiers—can no longer keep up with the realities of commercial cultivation.

One of the first things growers usually notice is what happens at night. The lights go off, transpiration drops fast—but the moisture doesn’t magically leave the room. Conventional HVAC systems, built for human comfort, just can’t keep up with that sudden shift in latent load. Humidity spikes, RH starts wandering, VPD drifts, and plants end up spending hours outside their sweet spot, day after day.

Another red flag is when the equipment starts working against itself. The air conditioner cools the room, the dehumidifier reheats it, and both end up cycling nonstop. Or worse—running constantly. Power bills climb, but climate stability actually gets worse, especially as plant density increases and rooms get larger. More capacity doesn’t fix it; it just amplifies the chaos.

This breaking point often shows up when different rooms need different rules. Veg rooms behave one way. Flower rooms another. Dry rooms play by a completely different set of physics. Traditional setups don’t have the coordination or precision to handle that kind of complexity. Control turns reactive—chasing numbers instead of holding them—and consistency from one cycle to the next starts to slip.

At that point, the issue isn’t fine-tuning setpoints or swapping out a single piece of equipment. It’s the system design itself. Cannabis HVAC systems are built specifically for commercial grow rooms, where temperature, humidity, and airflow have to be managed independently, around the clock, and at scale. When climate instability starts cutting into yield, quality, and operating costs, moving to a purpose-built cannabis HVAC system isn’t just a nice upgrade—it’s the only real way forward.

Here’s Why Traditional HVAC Systems Fail in Cannabis Grow Rooms

Most traditional H.V.A.C. systems were designed for people, not plants. Offices, stores, warehouses — those spaces generate fairly predictable heat loads and humidity is typically something you address later or not at all. Grow rooms are a whole other matter. When it comes to growing cannabis, moisture control is not only important — it's a factor that in some instances matters equally with temperature, sometimes even more so.

A massive culprit is latent load. It’s not just about how much moisture there is but when it occurs. Cannabis plants emit mind-boggling amounts of moisture into the air, and that load fluctuates. The room cools off quickly when the lights go out, but the humidity doesn’t vanish into thin air. Most traditional HVAC systems aren’t designed for that kind of mismatch. So the swings of humidity begin, set points are overshot and your VPD can ride for hours instead of settling in as it should.

And then there is the manner in which most systems are cobbled together. In most grow rooms, cooling is provided by an air conditioner and humidity is controlled by independent dehumidifiers. Technically, they are each doing their jobs — but not together. The AC cools the room, the dehumidifier re-heats it, the AC kicks back in to cool it all over again… and so on. It’s a hungry loop for energy and somehow ends up more expensive while delivering less stability.

Another reality traditional HVAC struggles with is that grow rooms never really stop. Veg rooms, flower rooms, drying rooms—something is always running, 24/7. Comfort cooling equipment expects downtime. Grow rooms don’t give it any. Over time, that means long run hours, short cycling, and parts wearing out much sooner than planned, especially when moisture levels stay high day after day.

Things get even messier once you’re dealing with multiple rooms. Each room behaves differently—different heat loads, different moisture patterns, different airflow needs, different targets. Conventional HVAC systems don’t do a great job coordinating all of that. Instead of holding steady conditions, growers end up chasing numbers, constantly adjusting settings just to stay afloat.

None of this is really about bad equipment or poor installation. It’s a design issue. Traditional HVAC architectures were never meant for nonstop operation, fast-changing moisture loads, and the tight environmental control commercial cannabis demands. That’s why, sooner or later, a lot of growers hit a wall with patchwork solutions and start looking toward purpose-built cannabis HVAC systems designed specifically for grow room environments.

What Makes a Cannabis HVAC System Different?

A cannabis HVAC system is not a modified comfort cooling solution. It is a category of climate control systems specifically engineered around the biological and operational realities of commercial cannabis cultivation.

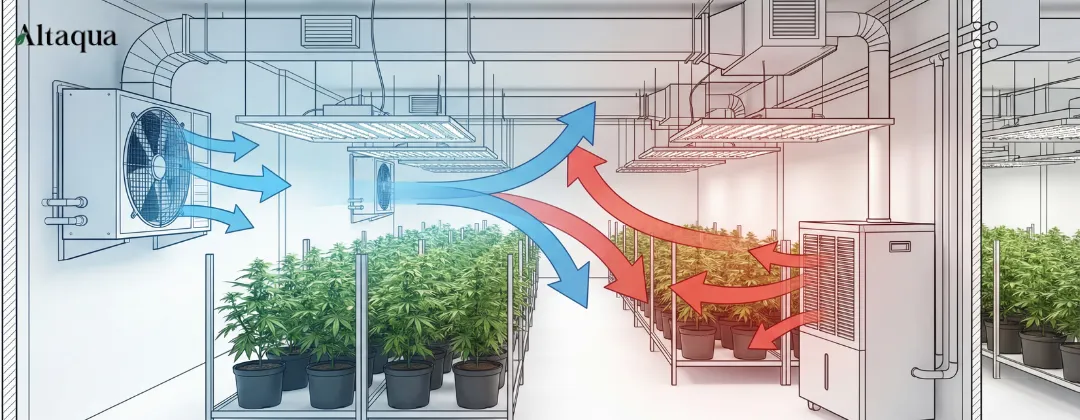

The biggest difference starts with independent control of temperature and humidity. In a grow room, those two loads almost never move in sync. Plants keep dumping moisture into the air even when heat drops, especially once the lights go out. Cannabis HVAC systems are built around that reality. They can manage latent moisture and sensible heat separately, so you can pull humidity out of the room without constantly swinging the temperature up and down.

Another key difference is that the whole system is designed around plant behavior, not people. Grow rooms don’t act like offices or warehouses. Conditions shift fast and predictably based on light cycles, plant density, and growth stage. Purpose-built cannabis HVAC systems are sized and configured to ride through those changes smoothly, keeping veg, flower, and drying rooms stable without someone constantly chasing settings.

They’re also built for nonstop, precision operation. Commercial cultivation doesn’t pause, and high moisture is always part of the equation. Conventional equipment tends to struggle under those conditions. Cannabis HVAC systems use components, airflow design, and control logic meant for long runtimes, reduced short cycling, and tight environmental control—day after day, cycle after cycle.

Equally important is integrated system coordination. Temperature, humidity, airflow, and control are designed to work as a unified system rather than as separate devices reacting to one another. This integrated approach reduces energy waste, improves environmental consistency, and simplifies long-term operation as facilities scale or expand.

In other words, there are no cannabis HVAC systems by way of brand or form factor; they’re distinguished by purpose. They are designed to provide consistent, repeatable growth environments in locations where climate determines production yield, quality and cost of operation. This core difference is what has positioned cannabis HVAC as a category of its own within commercial cultivation (as opposed to traditional HVAC design that’s been tinkered with).

How Cannabis HVAC Systems Improve Yield, Energy Efficiency, and Consistency

In commercial cannabis cultivation, yield and quality aren’t defined by hitting perfect conditions once in a while. They’re shaped by how steady those conditions stay over time. Even brief swings in temperature or humidity can throw off transpiration, disrupt nutrient uptake, and quietly stress plants. Cannabis HVAC systems solve this by giving plants a stable environmental baseline—something they can count on from start to finish.

When VPD and humidity stay consistent, plants transpire at predictable rates. Growth evens out, stress-related variability drops, and genetics tend to express themselves more reliably from one run to the next. Over time, that stability shows up as more uniform canopies, tighter harvest windows, and fewer quality surprises between batches.

Energy efficiency improves for a different reason than most people expect. It’s not about running equipment harder—it’s about stopping systems from fighting each other. In traditional setups, air conditioners cool while dehumidifiers reheat, burning energy without actually improving stability. Integrated cannabis HVAC systems bring cooling, dehumidification, and airflow under one coordinated control strategy. That cuts down short cycling, unnecessary reheating, and wasted runtime. The real payoff is lower energy use per pound produced, not just better-looking kWh numbers on paper.

Control strategy is another biggie, especially in commercial installations with premises managed across a dozen rooms. Veg rooms act different than flower rooms which acts different than drying rooms, and all have varying targets. An intelligently designed cannabis HVAC must be able to manage control throughout the facility, keeping conditions tight and minimizing deviation without transforming day-to-day operations into a juggling act.

And there is reliability — because grow rooms don’t take days off. High humidity is not a periodic problem, it’s an everyday reality. That also means the equipment, sensors and control logic must all be chosen with the long run times and real-world conditions in mind. Redundancy matters. Stability matters. And maintenance has to be practical for a real facility, not some clean lab that never materializes in the world.

From a zoomed-out perspective, the decision in outfitting the appropriate HVAC system for your cannabis project comes down to intent. Systems designed for commercial cultivation are made to maintain consistent climates, provide repeatable results, and scale without endless migraines. Systems built from mods of old-school HVAC can check out OK on a spec sheet but, over time, they all too easily become the weakest link — the bottle neck no one was expecting while everything else kept bending and going in between.

Choosing the Right Cannabis HVAC System for Commercial Facilities

Picking a cannabis HVAC system isn’t really about chasing a brand name. It’s about whether the system was designed for how grow rooms actually behave—or whether it’s still built around comfort-cooling assumptions. The right system needs to match how plants load a room, both thermally and biologically, as they move through different stages of growth.

One of the first things to look for is true, independent control of temperature and humidity. In commercial grow rooms, you can’t treat moisture removal as a side effect of cooling. Systems that rely on overcooling and reheating to manage humidity tend to burn energy and still struggle to hold stable VPD. A purpose-built cannabis HVAC system should handle latent and sensible loads separately, without forcing one to chase the other.

Load calculations matter just as much. A lot of systems fail simply because they were sized using standard HVAC rules that focus on room size and ignore what the plants are doing. Plant density, lighting schedules, canopy development, and lights-off humidity all change the load dramatically over time. A system designed for cannabis should account for how those loads evolve throughout the cycle—and respond without someone constantly tweaking setpoints.

Control strategy is another big one, especially in commercial facilities with multiple rooms. Veg rooms, flower rooms, and drying rooms all behave differently and need different targets. A well-designed cannabis HVAC system should coordinate control across those spaces, keeping conditions tight without turning day-to-day operation into a juggling act.

And then there’s reliability—because grow rooms don’t get days off. High humidity isn’t an occasional issue, it’s part of everyday operation. That means the equipment, sensors, and control logic all need to be selected with long runtimes and real-world conditions in mind. Redundancy matters. Stability matters. And maintenance has to make sense for an actual facility, not some clean lab scenario that never really exists in practice.

When you zoom out, choosing the right cannabis HVAC system is really about intent. Systems designed specifically for commercial cultivation are built to hold steady climates, deliver repeatable results, and scale without constant headaches. Systems adapted from traditional HVAC designs might look fine on a spec sheet, but over time, they often turn into the weak link—the bottleneck no one expected when everything else keeps pushing forward.

Conclusion

For most of these cannabis growers, changing the ways in which they control their environment doesn’t begin with a huge expansion or a new space at all. It generally starts with a much softer epiphany: the current setup isn’t coming up short because it’s undersized — it’s coming up short because it wasn’t designed for a grow room in the first place.

When temperature and humidity affect yield, quality, or cost of operation directly then climate control is no longer just a bunch of add-ons; it’s an essential part the production process. Then fine-tuning specific setpoints or plugging in another stand-alone device don’t necessarily solve the problem. It just delays the inevitable. The architecture of the system is already saturated."

That’s where cannabis HVAC is the game changer. It’s the shift away from repurposed comfort-cooling solutions to environmental control designed specifically for plants, nonstop operation, and commercial-scale consistency. Rather than responding when the trouble turns up, it shifts to preventing the issues to begin with by establishing stable, repeatable control.

In commercial growing, the key to long-term success is not about striking perfect conditions once and “putting your hands together and hoping.” It was about establishing the correct conditions, run after run. When volatile climate conditions begin to take a bite out of profits, an upgrade to a cannabis HVAC system is no longer considered a “treat”. It’s a structural decision that lays the foundation for control, scalability, dependable operation in the future.

FAQ

1、What is a cannabis HVAC system?

A cannabis HVAC system is a climate control system built specifically for commercial cannabis cultivation. Unlike standard HVAC equipment meant for people, these systems are designed around how plants actually behave—constant moisture release, fast environmental shifts, and nonstop operation. They control temperature and humidity independently, which helps keep the grow room stable and plants performing consistently from start to finish.

2、How is cannabis HVAC different from standard commercial HVAC?

Most commercial HVAC systems are designed for predictable heat loads and on-and-off use. Grow rooms don’t work that way. Cannabis HVAC systems are built to handle heavy moisture loads, run 24/7, and hold tight environmental targets like VPD. That difference in design is what allows them to stay stable without wasting energy or having cooling and dehumidification fight each other.

3、When should a grower upgrade to a cannabis HVAC system?

Growers usually reach this point when AC units and standalone dehumidifiers stop keeping up—especially at night when humidity spikes after lights go off. Ongoing VPD drift, rising energy bills, rooms behaving inconsistently, and constant manual adjustments are all signs that the current setup has hit its limits and the system architecture itself is the problem.

4、Is a cannabis HVAC system only necessary for large-scale facilities?

Cannabis HVAC systems matter most in commercial operations where plant density is high, production runs continuously, and environmental margins are tight. Smaller grows may get by with simpler setups for a while, but facilities aiming for consistent yield, predictable quality, and long-term scalability often reach a point where a purpose-built cannabis HVAC system becomes necessary—no matter the total square footage.

Share with your friends:

Popular Blogs on Altaqua:

Download Catalogue