Mastering Efficient Cannabis Climate Control for Optimal Growth

Growers often face a common problem. Even when nutrients are well balanced and equipment is reliable, cannabis plants may still grow slowly, produce unstable yields, or show signs of mold and pests again and again. In most cases, these issues are closely related to poor cannabis climate control.

This article will help you understand the key factors in cannabis climate control. It will also explain what problems may happen if the climate is not managed well. Then, it will compare different types of climate control systems and show their strengths and weaknesses. In the end, you will learn how a dedicated HVAC system can help growers create the right grow room environment. This can lead to higher yields and better-quality cannabis.

What Key Parameters Are Involved in Cannabis Climate Control?

In cannabis cultivation, climate control means managing many environmental factors at the same time. These factors are connected. If one of them becomes unbalanced, it can affect the plant’s growth, yield, and quality.

Temperature

Temperature is the basic condition for all cannabis plant activities. When the temperature is suitable, plant cells become more active. Photosynthesis, respiration, and nutrient transport all become more active. Warmer temperatures can increase enzyme activity and help leaves take in more light energy. This helps the plant create more sugars for growth and energy storage.

Temperature also affects how well roots absorb water and minerals. Warmer soil helps roots grow longer and absorb more nutrients. This gives strong support for above-ground growth. In addition, temperature can change the way plant hormones work. These hormones, like auxin and gibberellin, control cell division and flowering. Changes in temperature can change how long the plant’s stems grow, how wide the leaves become, and when the plant starts to flower. Good cannabis climate control helps keep these things stable.

Relative Humidity

Relative humidity affects the water flow inside the plant. Water moves through transpiration on the leaf surface. When humidity is at the right level, the plant opens its stomata to release water vapor. This creates an upward pull that brings water and nutrients from the roots to the leaves and flowers.

In this way, humidity plays a direct role in the plant’s breathing, nutrient transport, and cooling. It helps the whole plant system work normally. That is why controlling humidity is a key part of cannabis climate control.

Vapor Pressure Deficit

VPD is a number based on both temperature and humidity. It shows how easily water leaves the plant. When the VPD is in a good range, the plant can keep transpiring. This moves water and nutrients from the roots to the leaves, stems, and flowers.

This process helps the plant carry out normal metabolism. It also supports cell expansion, division, and growth. A proper VPD range helps the cannabis plant grow in a healthy way. That is why VPD is an important part of cannabis climate control.

Airflow and CO₂ Levels

Airflow keeps the air moving in the grow space. This helps keep the area around the plant stable. During photosynthesis, the plant takes in CO₂ and gives out oxygen. Good airflow brings fresh air to the leaves. This gives enough CO₂ and helps with gas exchange.

Airflow also creates a light touch on the plant surface. This helps the stems grow stronger so they can hold larger leaves and flowers. CO₂ is the material plants use to make sugars. With enough light, plants take in CO₂ and water to produce glucose. This is used for growth and development. That is why steady airflow and proper CO₂ levels are important for cannabis climate control.

Light Intensity and Photoperiod

Light is the direct energy source for photosynthesis. Plants use chloroplasts to take in light. They turn CO₂ and water into sugars. These sugars are used for cell growth, division, and expansion. When light intensity is proper, the plant uses more light. It makes more energy for leaf growth, root expansion, and flower formation.

The length of the light period also affects the plant’s growth stage. Cannabis is very sensitive to light cycles. When the plant gets long light hours each day, it stays in the vegetative stage. It keeps growing leaves and stems. When the light hours become shorter, the plant starts the flowering stage. It forms buds and begins reproductive growth.

Common Issues and Risks When Cannabis Climate Control Fails

Cannabis climate control is a long-term and careful task in cannabis cultivation. If growers make mistakes or the system becomes unstable, it can easily harm the entire crop. Unstable environmental conditions break the plant’s normal growth rhythm. This makes the plants more likely to suffer from diseases, pests, and outside stress. Below are some common problems and how they affect plant health and yield step by step.

Mold and Mildew Problems

In closed grow rooms, unbalanced humidity and poor airflow often cause fungal diseases. These problems happen easily when the relative humidity is too high and the air is not moving well. Fungal spores can spread through the air and infect leaves, stems, and flowers.

Diseases like Botrytis and powdery mildew are common. They create visible white mold or powder on the plant's surface. This slowly reduces photosynthesis, weakens plant tissues, and affects flower development and quality.

During the late flowering stage, if humidity is not controlled, water may build up in the flowers. This increases the risk of mold outbreaks and lowers the value of the whole harvest. Once mold gets inside the plant, it is hard to remove and spreads fast. That is why cannabis climate control must be used as the first line of defense.

Poor Yield and Stunted Growth

If the cannabis climate control system cannot keep the environment stable, it will disturb the plant’s normal growth and metabolism. Plants may grow slower, store less nutrition, and give lower yield and quality. This kind of damage is often hard to see at first. But once it reaches key growth stages, it is difficult to fix.

Inconsistent Temperatures and Their Effects

Plants rely on stable temperature for healthy metabolism. Big temperature changes can disturb plant hormones and enzyme activity. This also affects the balance between photosynthesis and respiration.

When there is a big temperature difference between day and night or when changes happen too often, plants become stressed. They work less efficiently, and cell growth slows down. Leaves become smaller and spaces between nodes become shorter. The plant’s structure and ability to absorb light will both suffer.

How VPD Imbalance Slows Down Nutrient Uptake

When the vapor pressure deficit (VPD) is not in the right range, transpiration becomes weaker. This makes it harder for the roots to send water upward. Nutrients dissolved in the water cannot reach the leaves and flowers well.

Some nutrients stay in the roots. The upper parts of the plant don’t get what they need. Growth becomes slower. Over time, this limits how tall the plant can grow and stops flower development.

Linking Climate Issues to Chemical Compound Reduction

In cannabis plants, compounds like THC and CBD are called secondary metabolites. Plants can only produce them well when metabolism is stable. This needs a well-controlled climate.

If temperature, humidity, VPD, or lighting changes too often, plant metabolism slows down. The plant uses more energy to stay alive and repair itself. It cannot focus on making THC and CBD.

This problem is more serious in the late flowering stage. If climate conditions are not kept in the right range, the plant will produce fewer active compounds. This may not affect how the flower looks, but lab tests will show lower THC and CBD levels. This lowers the product’s quality and market value.

Pest Infestations

Bad temperature and humidity or poor airflow make it easy for pests like aphids, spider mites, and whiteflies to grow fast. At the same time, plants under stress lose some of their natural defenses.

For example, stomata control becomes weak and cell walls become soft. Pests can then suck plant juices more easily. Pests also carry harmful bacteria or fungi. These can cause more serious diseases. In the end, pests can damage flowers and lower the final product quality.

Increased Energy Costs and System Strain

When cannabis climate control fails, equipment like air conditioners, dehumidifiers, humidifiers, and fans must work harder and longer to meet set points. This leads to much higher energy use and rising operating costs.

It also makes equipment wear out faster. The system becomes less stable. If the grow room has no backup design or zoning control, one device failure can cause climate problems in the whole area. This puts even more stress on the plants.

What Are the Common Cannabis Climate Control Systems?

There are several types of cannabis climate control systems. Each one has different designs, uses, and advantages. But they also come with certain limits when used in grow rooms.

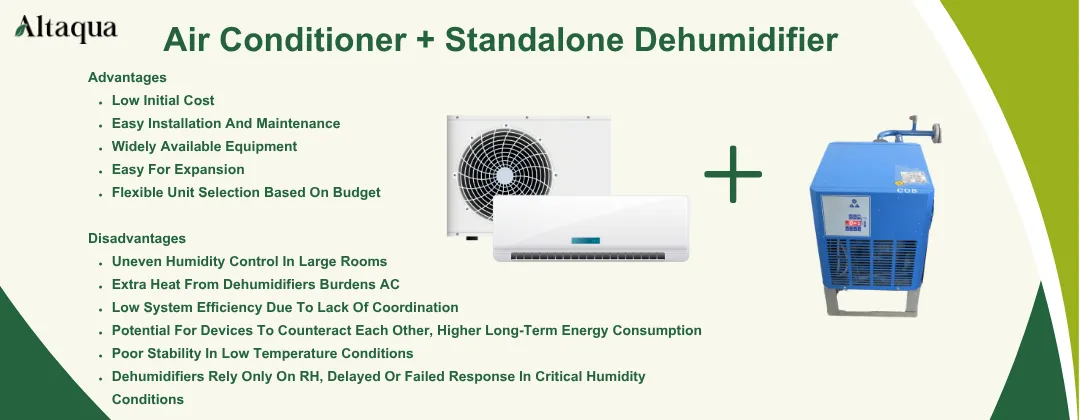

Air Conditioner + Standalone Dehumidifier

The combination of air conditioners and standalone dehumidifiers is a common setup in cannabis growing. In this system, different machines control temperature and humidity separately. This gives growers more flexibility and space to expand. But this setup also has some limits when used in cannabis climate control.

System Design: Decoupled Temperature and Humidity Control

The air conditioner and dehumidifier do different jobs. The air conditioner controls the sensible load, which means it changes the air temperature. The dehumidifier handles the latent load, which means it removes moisture from the air.

These machines work separately. When used together in grow rooms, they can control temperature and humidity independently. This gives growers more accurate and flexible control of the environment.

More and more cannabis growers have started using this setup in recent years. That is because cannabis plants need stricter climate conditions than regular buildings. Also, different plant stages require different climate levels. This setup can meet the basic needs of temperature and humidity control in grow rooms.

Where This Setup Is Commonly Found

This setup is mostly used in small and medium-sized grow rooms. It is often found in retrofitted factories, early-stage projects with limited budgets, or expanding facilities.

Key Benefits

This type of cannabis climate control system is popular because it has several clear advantages. First, it has low initial cost. It is also easy to install and maintain. It offers system safety by using multiple machines.

In early construction, this system does not need complex piping or a central control platform. The equipment is widely available. The market is mature, and the price per unit is low. Growers can choose different units based on their budget. They can also buy equipment step by step. This reduces the pressure of one-time investment.

Second, this system is simple to install and maintain. It only needs basic power and drainage connections. It is not limited by room layout. Each device can be checked and fixed independently. Replacing parts is easy. There is no need to shut down the whole system. This helps the grow room keep running without pause.

Also, this system usually includes several separate devices. If one machine fails, others can still work. This lowers the risk of total system failure.

Drawbacks in Cannabis Environments

Even though this system is flexible and affordable, it has some problems when used for cannabis climate control. First, the dehumidifiers are placed in different parts of the room. Each one can only control the humidity around it. In large grow rooms, this makes it hard to keep humidity even. Some spots may become too wet or too dry.

Second, dehumidifiers produce a lot of heat when running. If the room is already hot, this heat makes the air conditioner work harder. This lowers the overall efficiency and increases energy use. Since the air conditioner and dehumidifier are not connected, they cannot work together well. Sometimes, they may cancel each other’s efforts. This leads to poor climate balance.

In addition, ordinary split air conditioners have reduced performance under low temperature conditions, making it difficult to ensure temperature stability at night or in winter. Independent dehumidifiers cannot identify dew point and true moisture content, and can only rely on relative humidity parameters to determine operating status. Under certain specific climatic conditions, this control method may fail, causing the system to be unable to start the dehumidification function during critical periods, thereby increasing potential humidity risks during the planting process.

Variable Refrigerant Flow (VRF) Systems

VRF systems are a type of central air conditioner made for commercial buildings. They have strong temperature control abilities. Some growers have started using VRF systems for cannabis climate control.

System Design

VRF systems are also called multi-split systems. One or more outdoor units connect to many indoor units. Each indoor unit can control cooling or heating for its own space.

VRF systems use variable-speed compressors and electronic expansion valves. These parts adjust the refrigerant flow. This lets the system manage energy better and control each zone independently. It is a good choice for buildings that need accurate temperature control in different areas.

Widely Used In These Environments

VRF systems are often used in office buildings, hotels, hospitals, schools, and high-end homes. These places usually have many separate rooms with different uses. These places need flexible and comfortable indoor temperatures. VRF systems can adjust cooling based on changes in each space. They can also control many zones from one system. That is why VRF is used in places with clear zoning and steady temperature needs.

Notable Benefits

VRF systems are known for strong zone control, easy installation, and good energy efficiency. In a building with many rooms, a VRF system can meet different temperature needs. It sends more or less refrigerant to each room.

Indoor units in VRF systems come in many types. They are small and take up little space. They do not need big air ducts. They use copper pipes to move refrigerant. The system runs quietly and needs little maintenance. It is a stable and trusted solution in commercial buildings.

Weaknesses When Applied to Cannabis Cultivation

Even though VRF systems are used in many buildings, they are not made for grow rooms. They were designed for human comfort, not for plant needs. In cannabis climate control, temperature and humidity must be managed together. VRF systems can only adjust temperature. When the room reaches the set temperature, the system stops. It cannot continue to remove moisture. So growers must add extra dehumidifiers.

But dehumidifiers release heat while running. When they work hard, they make the room hot. To cool the room again, the VRF system must run more. This uses more energy and makes the system start and stop often. This shortens equipment life and reduces stability.

More importantly, VRF systems cannot control dew point, VPD, or actual moisture in the air. They only respond to temperature. This is a problem when growers need accurate cannabis climate control. During late flowering or when plants release less moisture at night, the VRF system cannot respond well. It may not keep the right conditions for the plants.

Chiller Systems

Chiller systems are often used in large facilities and industrial settings. They are known for their high-efficiency cooling performance. In large-scale cannabis cultivation, chiller systems have become a solution worth considering for cannabis climate control.

System Design: High Latent Load Capability

A chiller system uses a central chiller unit to produce cold water. This cold water is pumped to air handling units or fan coil units. These devices use the cold water to absorb heat from the air and cool down the grow space. This type of system is mainly designed to handle sensible heat. It is not very effective at removing moisture from the air.

Common Applications

Chiller systems are widely used in large commercial buildings, hospitals, factories, data centers, hotels, and high-end laboratories. These places are usually large, with concentrated heat loads and stable cooling needs. A central cooling system works well in such conditions.

Chiller systems are also used in industrial processes such as injection molding, electronics manufacturing, and food processing. These processes require strict control of equipment temperature. They need a stable supply of chilled water. In recent years, with the development of agriculture, some high-end greenhouses and vertical farms have started using chiller systems. This helps them improve environmental control accuracy and energy efficiency.

Technical Advantages

Chiller systems offer strong advantages in climate control. First, the system delivers steady cooling output and high energy efficiency. It performs well during continuous use. Water is a good heat carrier. It transfers heat quickly and flows steadily. It can keep temperature differences small. This helps maintain even temperatures across large spaces.

Second, the system structure is flexible and easy to manage. The central chiller provides cooling to all areas. The end units can adjust their operation based on different zone needs. This makes chiller systems suitable for large and complex projects. During operation, the system produces low noise and little vibration. It lasts a long time and stays stable over time.

Limitations in Cannabis Cultivation: Poor Dehumidification Performance

Although chiller systems are very good at controlling temperature, they have clear limits in cannabis climate control. Their main weakness is poor humidity control. In cannabis grow rooms, there is often a lot of water vapor in the air. This is especially true after lights turn off and plant transpiration slows down. At that time, the humidity rises quickly. A chiller system alone cannot remove enough moisture.

To reduce humidity, the system must cool the air to a very low temperature. The chilled water must be at least 5 to 7 degrees Fahrenheit lower than the dew point. This increases energy costs. Also, the cooled air is very cold. It must be reheated before entering the grow room. This prevents cold damage to the plants. If there is no built-in reheating function, growers may need to add another heat source to warm the air to a safe level.

In addition, since the chiller system cannot remove moisture well, it often needs to work with standalone dehumidifiers. But dehumidifiers produce heat. The chiller must then cool the air again. This back-and-forth process is not efficient. It increases energy use and puts more strain on the system.

Finally, chiller systems are harder to install and maintain. The system includes a main chiller, pumps, pipes, controls, and end units. All of these parts must work together. Installation takes a long time and needs skilled work. During maintenance, workers must check water quality, remove scale, and keep the water flow efficient. Because of this, the cost to build and run the system is higher than regular AC or dehumidifier setups. Chiller systems are not a good choice for small or budget-limited cannabis grow rooms.

Using Altaqua Grow Room HVAC System for Cannabis Climate Control

In cannabis cultivation, stable and accurate climate control is the key to good yield and quality. Altaqua Grow Room HVAC System combines advanced sensors, automatic control logic, and remote operation features. It helps growers fully manage the growing environment. It also improves efficiency and reduces risks.

Use Dew Point Control for Precise Humidity Control

In cannabis climate control, humidity affects plant health, growth speed, and yield. To control humidity well, it is not enough to only watch relative humidity. It is more important to know how much water is really in the air. That is why dew point temperature is a better standard.

Relative humidity changes when temperature changes. It does not show the real amount of moisture in the air. For example, if water vapor in the air stays the same, the relative humidity goes down when the temperature goes up. If the temperature drops, the relative humidity goes up. This makes it easy to judge the wrong conditions. Then, the dehumidifier may not respond in time. That can break the stability of the grow room.

Altaqua Grow Room HVAC System uses dew point temperature to control humidity. This avoids the limits of using relative humidity. The system watches the dew point in real time. It compares the actual value to the target setting. If the dew point is too high, this means there is too much water in the air. The system will start dehumidifying right away. Once the dew point drops back to a safe level, the system stops the dehumidification automatically.

Advanced Sensor and Monitoring Technologies

In cannabis growing, the environment changes all the time and often in small ways. To control the climate well, growers need more than stable equipment. They also need a strong monitoring system. Altaqua Grow Room HVAC System uses high-precision sensors and smart monitoring tools. These help growers clearly understand the real-time environment in the grow room. This gives a solid base for automatic control and future adjustments.

Real-Time Data Collection and Feedback Loops

The system uses high-quality temperature and humidity sensors from the E+E brand. These sensors check temperature, relative humidity, and CO₂ levels in the grow room all day and night. The data is collected often and sent straight to the central controller.

The controller uses this real-time data to adjust cooling, dehumidification, and ventilation. This keeps the grow room within the set climate range. The fast response improves the climate control effect. It also avoids delays that can happen with manual changes.

Remote WiFi Control

Altaqua Grow Room HVAC System supports wireless control through WiFi. Growers can use a phone, computer, or tablet to check the grow room status anytime and anywhere. They can also change settings remotely. No matter where they are, users can know how the system is running. This makes real-time remote management possible.

Cloud-based control helps reduce labor and management costs. It also makes the system respond faster and stay steady all the time. The system also supports the Modbus communication protocol. This means it can connect with other building systems. Growers can control all devices and zones from one platform. This makes cannabis climate control easier and more centralized.

Automation and Smart Controls

For cannabis growers, good climate control is not just about having the right equipment. It also needs smart control and automatic adjustments. Our system has a built-in automation platform. It works with Siemens PLC and custom logic. The system can match different growing stages and reduce the need for manual control. This improves efficiency and gives growers more control.

Scheduling by Plant Growth Stages

Cannabis needs different temperature, humidity, and light settings at each growth stage. Altaqua Grow Room HVAC System lets growers set different parameters ahead of time. The system will change the mode automatically as the plants grow. This makes sure the environment is right for every stage. It helps keep the yield high and the product quality stable.

Alarm Systems and Fail-Safes to Prevent Critical Failures

To keep the system running safely for a long time, Altaqua includes many safety features. These include phase protection, high-pressure protection, and low-pressure protection. If the system finds a problem, it shows a message on the Siemens PLC panel. It also sends an alert through WiFi to the user’s device.

This design helps growers know about the problem quickly. They can take action right away, either by changing settings or by planning a repair. This protects the plants from damage caused by sudden equipment failure.

Energy Efficiency Strategies

Grow room HVAC systems often run for long hours and handle heavy loads. Many growers face the real challenge of keeping the climate stable while reducing energy use. Altaqua Grow Room HVAC System focuses on energy saving from equipment selection to operating logic. It works to lower running costs while still meeting cannabis climate control needs.

EC Motor Fans and Dynamic Airflow Control

The system uses high-efficiency EC motor fans. These fans can adjust their speed automatically. They respond to different times of day and different plant needs. This allows them to deliver the right amount of airflow without running at full speed all the time. This saves energy and also protects the plants from stress caused by strong airflow.

The EC fans are also quiet, long-lasting, and easy to maintain. They are suitable for stable, all-day operation in grow rooms. The fans work closely with the temperature and humidity control system. This creates airflow only when needed and improves air circulation. As a result, temperature and humidity are more evenly spread in the grow space. This supports better cannabis climate control.

Waste Heat Recovery and Dehumidification Integration

During dehumidification, the system produces a lot of heat. Our system can collect this heat through its built-in heat recovery design. It reuses the heat to warm the air again. This prevents the space from becoming too cold. It also saves the extra power that would be needed to reheat the air.

In traditional systems, dehumidification and reheating often come from two separate machines. This leads to more energy use and slower response. Altaqua Grow Room HVAC System combines dehumidification and reheating in one system. All parts work together with the same logic. This improves efficiency and keeps performance steady. The air stays dry, and the temperature stays balanced. This helps keep the cannabis grow environment stable and easy to manage.

Conclusion

In cannabis cultivation, accurate and efficient climate control systems are important for plant health. They also directly affect yield and quality. From temperature and humidity to VPD, airflow, and lighting, growers must carefully control many factors in the grow space.

Each traditional system has its own pros and cons. Altaqua Grow Room HVAC System combines dehumidification, cooling, heating, and smart controls into one solution. It offers a complete, energy-efficient approach to cannabis climate control. With real-time monitoring, dew point control, and remote access, the system solves common problems found in traditional equipment. It also helps growers make their environment more controlled and more sustainable.

FAQ

1. What Is Cannabis Climate Control and Why Is It Essential?

Cannabis climate control refers to the precise management of environmental factors such as temperature, humidity, airflow, CO₂ levels, and light within a grow room. These elements directly influence plant metabolism, growth rate, and cannabinoid production.

2. How Does Vapor Pressure Deficit (VPD) Impact Cannabis Growth?

VPD is a crucial indicator that combines temperature and humidity to reflect how easily moisture can evaporate from plant leaves. A well-balanced VPD promotes healthy transpiration, ensuring efficient nutrient uptake and supporting robust cell expansion and flower formation. If VPD is too high or too low, it can slow growth, limit biomass, and reduce cannabinoid content.

3. What Are the Risks of Poor Cannabis Climate Control?

When climate control fails, growers may experience a range of issues: mold and mildew due to high humidity, pest outbreaks in stagnant air, reduced yields from temperature swings, and higher energy costs from inefficient equipment use. Unstable environments also compromise the plant’s ability to produce secondary metabolites like THC and CBD.

4. Why Is Dew Point Control More Accurate Than Relative Humidity in Cannabis Grow Rooms?

Relative humidity (RH) fluctuates with temperature and doesn’t always represent the actual moisture content in the air. Dew point control, on the other hand, reflects the exact temperature at which air becomes saturated, offering a more stable and reliable method for managing humidity.

5. How Does Altaqua Grow Room HVAC System Help Automate Cannabis Climate Control?

Altaqua Grow Room HVAC System integrates high-precision sensors, Siemens PLC control, and smart scheduling based on plant growth stages. It automatically adjusts cooling, dehumidification, and airflow in real-time. With remote WiFi access and built-in alarms, growers can monitor and respond to changes instantly, improving operational efficiency and crop consistency.

Share with your friends:

Popular Blogs on Altaqua:

Download Catalogue