Energy Efficient Grow Room HVAC

Maximize Yields While Reducing Operating Costs

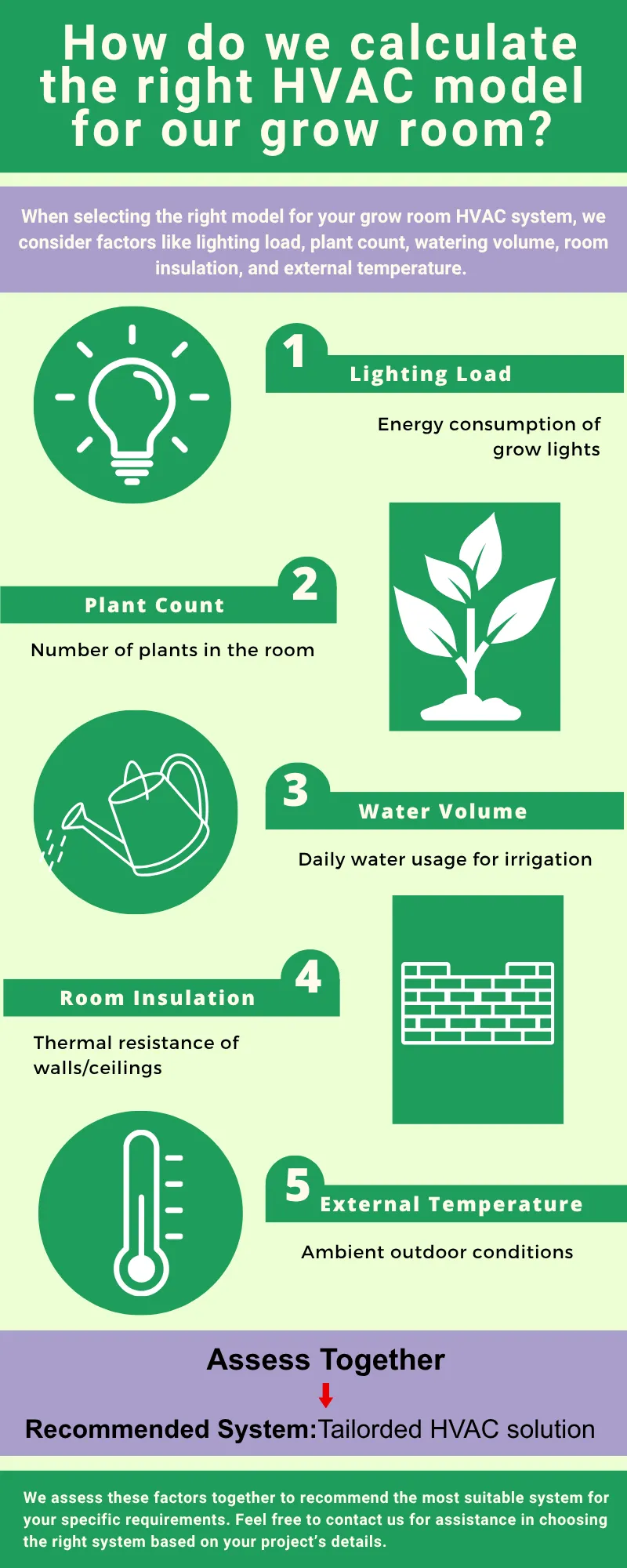

Selecting the right energy efficient grow room HVAC system isn’t a straightforward process and decision making should be made critically.

With so many available options it can get really hard to choose. What we do understand is that you need your HVAC system to suit your requirements, to afford dependable temperature and humidity regulation, and to operate efficiently in the long term. We aim to guideably assist you by providing enough answers about our products and their features to allow for easier product selection through the resources in our painstakingly put together FAQs.

If you are interested and would like to know more about it, please do not hesitate to contact us. We’re always glad to offer professional advice as you try to make the choice best suited for you.

We'll take into account lighting load, water volume, plant count, room insulation and outdoors temperature. We take all of these factors into consideration to recommend which system is best for your needs. Don't hesitate to contact us for help selecting the perfect system for your project specifics.

Yes, you can set up our HVAC for grow rooms outside; nevertheless, we would advise placing the major part indoors to shield it from extreme weather elements and decrease maintenance expenses. If indoor room is not available we recommend that at least a rudimentary roof or covering be used to protect the equipment.

As for the cooling condenser, it is designed to dissipate heat and must be installed outdoors to function properly.

Our standard models can operate stably in an environment temperature range from -5°C to 50°C. If you need to use the system in more extreme conditions, we can customize the equipment to support temperatures from -28°C to 55°C. To ensure proper functioning in low-temperature environments, we will add antifreeze components. For outdoor installations, the equipment will also be equipped with waterproof and UV-resistant panels to ensure durability.

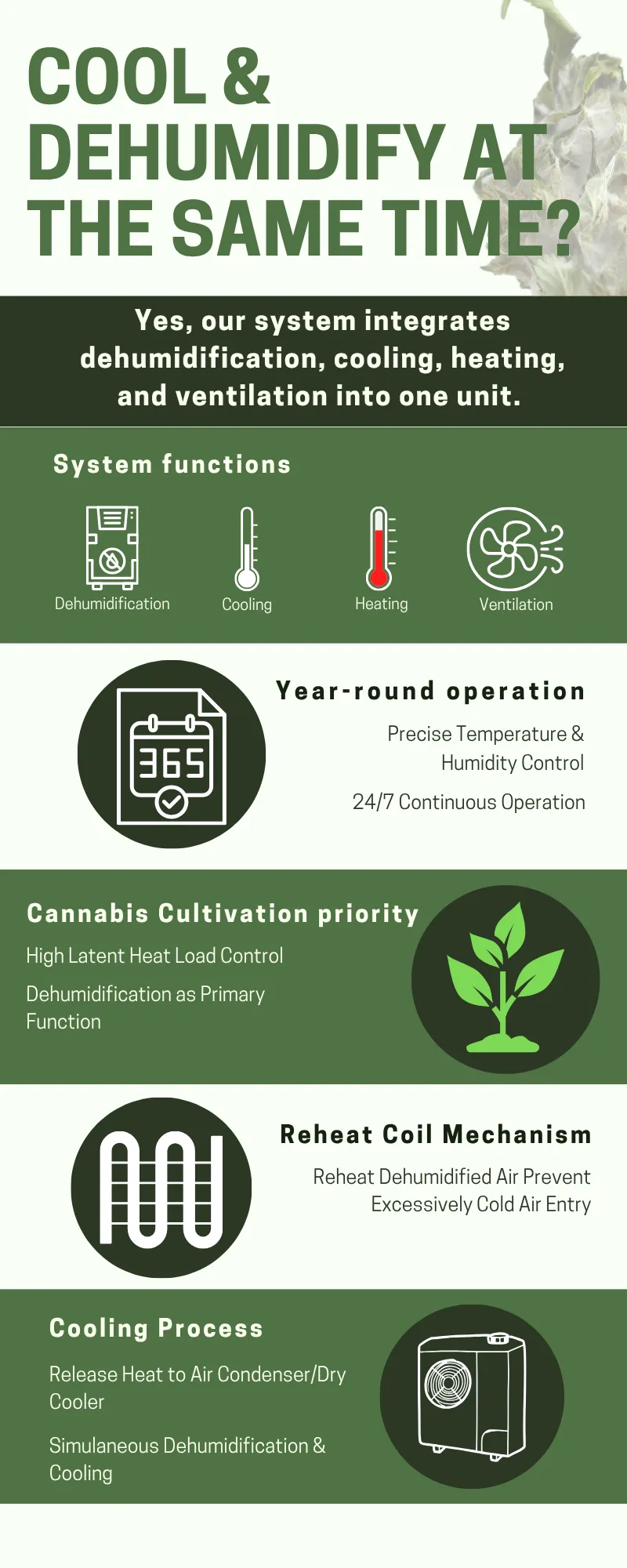

Yes, our system combines dehumiditying, cooling, heating and ventilation into one unit. Grow room HVAC works all year round as it can maintain temperatures and humidity accurately. It focuses on dehumidification to control the high latent heat load requirements of commercial cannabis growers.

It can dry out the air and reheat the room to prevent your grow room from cooling down too much, reheating the dehumidified air via a reheat coil. In addition, the air is simultaneously well cooled and dried whilst heat exchange of the air condenser or dry cooler with the system occurs.

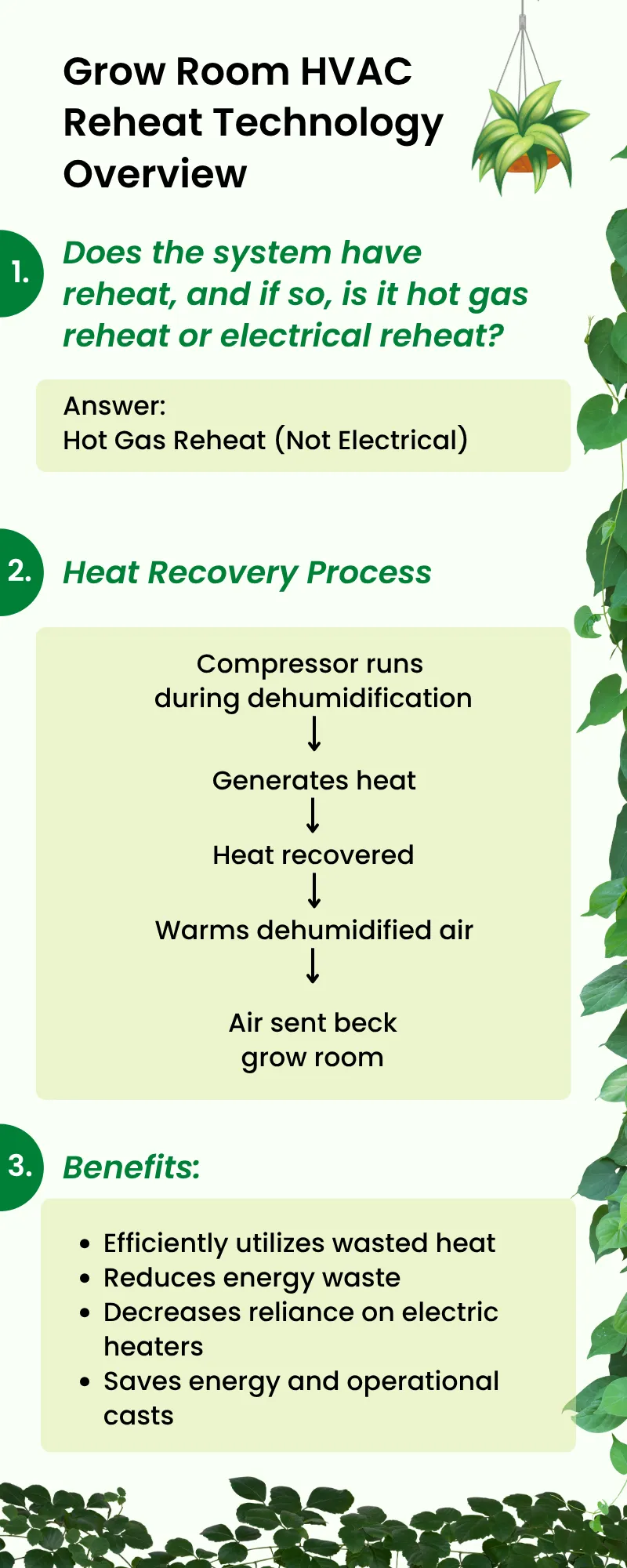

Our Grow Room HVAC series features a hot gas reheat and not electric reheat. When the compressor runs during dehumidification, it generates a large amount of heat. Our system captures this heat and applies it to the heating of the dehumidified air. The warm air is then recirculated in the grow room maintaining a perfect temperature and constant environment.

Hot gas reheat technology makes full use of the wasted heat, saves energy and power loss is small; it reduce the capacity of electric heater, so as to save energy consumption and operation cost.

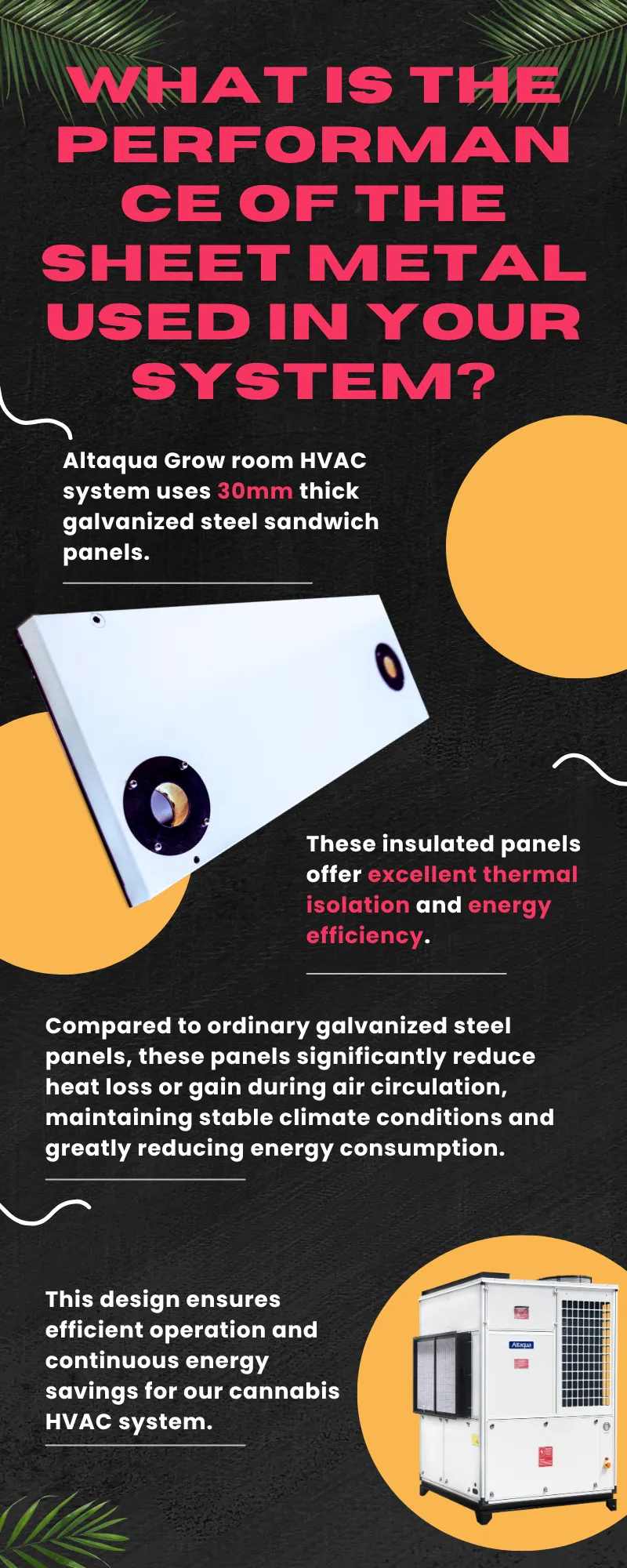

Altaqua grow room HVAC system with 30 mm thick galvanized steel sandwich panels. These type of insulated panels provide exceptional thermal insulation and energy efficiency. Compared with general galvanized plates, such a plate greatly reduces the incidence of heat loss or gain in an air flow process to keep stable temperature environment and remarkably cut energy cost. This design allows our grow room HVAC system to perform extremely well and provides perpetual energy savings.

Our standard filter rating on the grow room HVAC is MERV-8. This is because MERV-8 can effectively filter most common particles while maintaining low air resistance. We typically go with MERV-8 filters to give the system a fighting chance at maintaining reasonable airflow. If you need better air, we can move to MERV-13 filters.

Our grow room HVAC system can communicate through Modbus protocol or you can send a 24V signal from your controls to activate the equipment. This means you can readily connect our system to your current control system for added convenience and management.

Our grow room HVAC systems are ETL listed, confirming that they comply with U.S. safety standards. Furthermore, our company has accordance with international quality management and environmental manageme nt system of the ISO certification. These certifications are proof that we adhere to rigorous quality control standards in our design & manufacturing, and such guaranteed performance is the safety net of durability we provide our end users.

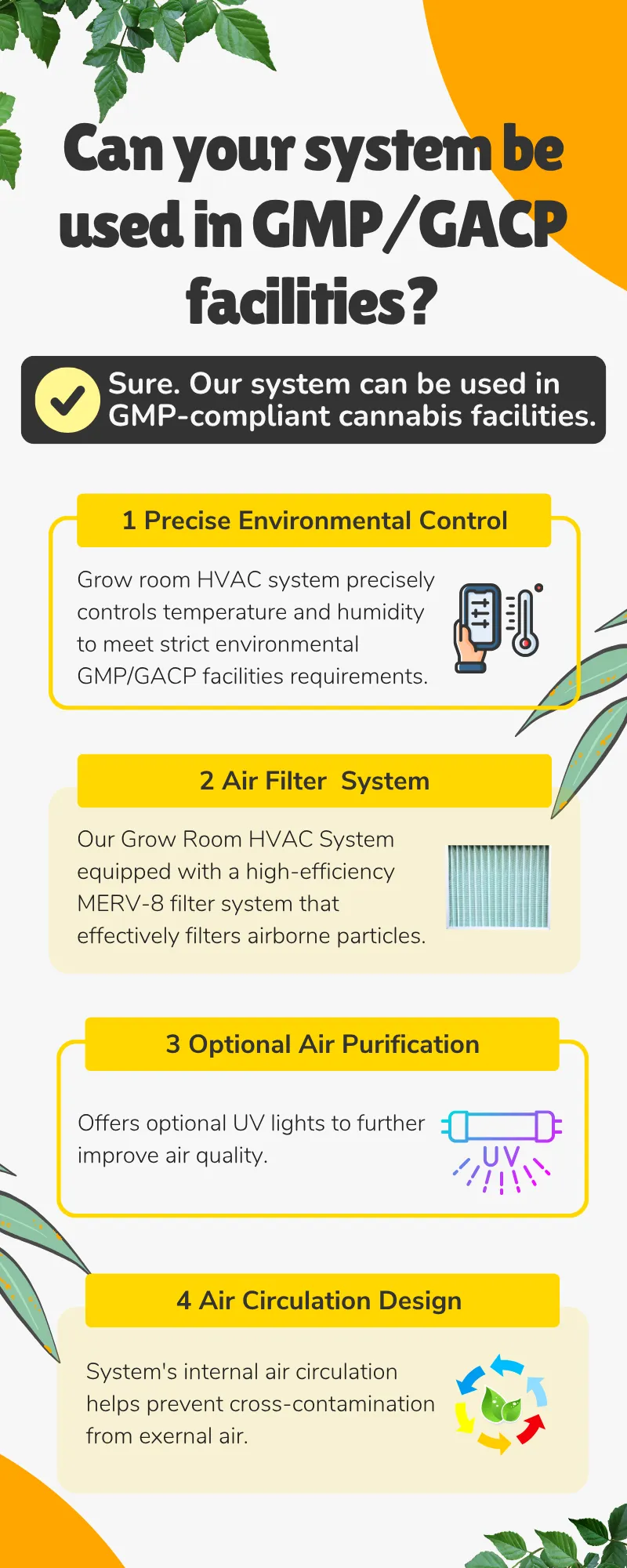

Sure. They can also be applied in GMP-compliant cannabis facilities. Our grow room HVAC systems can deliver the desired temperature and humidity to work within strict environmental conditions. It has a MERV-8 high efficiency filter media that captures airborne particles. We also offer optional UV lights to enhance the air quality in your grow facilities. The system is with an air circulating construction preventing cross contamination by external air and assures pure environment in the facility.