Purpose Built Cannabis HVAC

Traditional HVAC falls short for cannabis cultivation. Our purpose-built systems deliver precise control, greater efficiency, and long-term stability.

In cannabis commercial cultivation, some engineering companies still use traditional HVAC systems. They use them because these systems are widely used in large buildings such as hotels, and their performance has been proven over time.

However, a cannabis grow room is very different from a normal building. Cannabis plants need very precise temperature and humidity control during the whole growth cycle. At the late flowering stage, they need low temperature and very dry air. These special needs show many limits when traditional HVAC systems are used in cannabis grow rooms. For cannabis growers, traditional HVAC systems are not the best choice.

Limitations of Chilled Water Systems for Grow Room HVAC

A four-pipe chilled water HVAC system can provide cooling, dehumidification, and reheat in theory. But in real operation, it often brings complex system design, high energy use, and low flexibility.

A chilled water system must lower the water temperature to about 3°C (38°F) to meet dehumidification needs in the late flowering stage. Running at such low temperatures is highly inefficient. The air becomes too cold, which then requires extra reheating. This process adds even more energy consumption.

Cannabis grow rooms operate almost year-round without pause. Chilled water systems need constant low temp water and reheat. Energy use is much higher than unitary HVAC.

Chilled water systems require central cooling equipment, boilers, pump skids, long pipe networks, and complex control systems to work together. This makes construction and commissioning very difficult. Later maintenance and management also require a high level of expertise and cost.

A four-pipe chilled water system is extremely expensive to install. It needs large-diameter pipes. These pipes are heavy and take a long time to install. They also require strict insulation and safety measures, which adds to both cost and labor.

To prevent a full shutdown if the central chiller fails, growing facilities usually need multiple chillers, boilers, and backup pumps. This N+1 redundancy design adds a large extra cost to the total investment.

A chilled water system is a centralized solution. If the initial design capacity is too small, or if the cultivation scale changes later, expansion is very difficult. This approach is far less flexible than grow room HVAC systems designed for cannabis grow rooms.

Limitations of Decoupled Systems for Grow Room HVAC

In the early days of cannabis commercial indoor cultivation, many growers used split air conditioners together with standalone dehumidifiers to control the environment. These systems had low upfront cost and quick installation. For this reason, they were widely used in small and medium grow rooms.

However, as cultivation scaled up and growers required higher precision and efficiency, this “separate cooling and dehumidification” model showed many limitations.

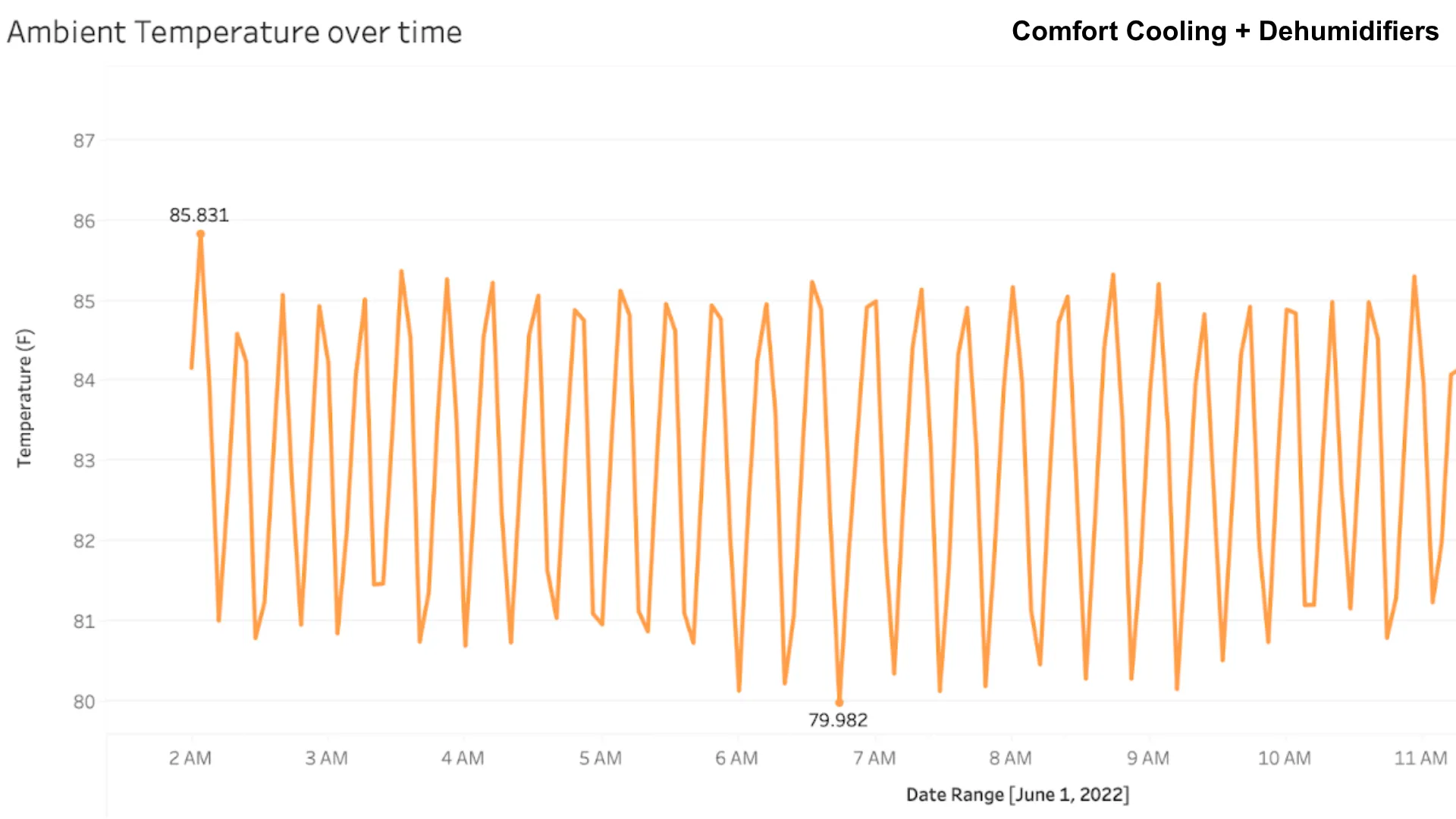

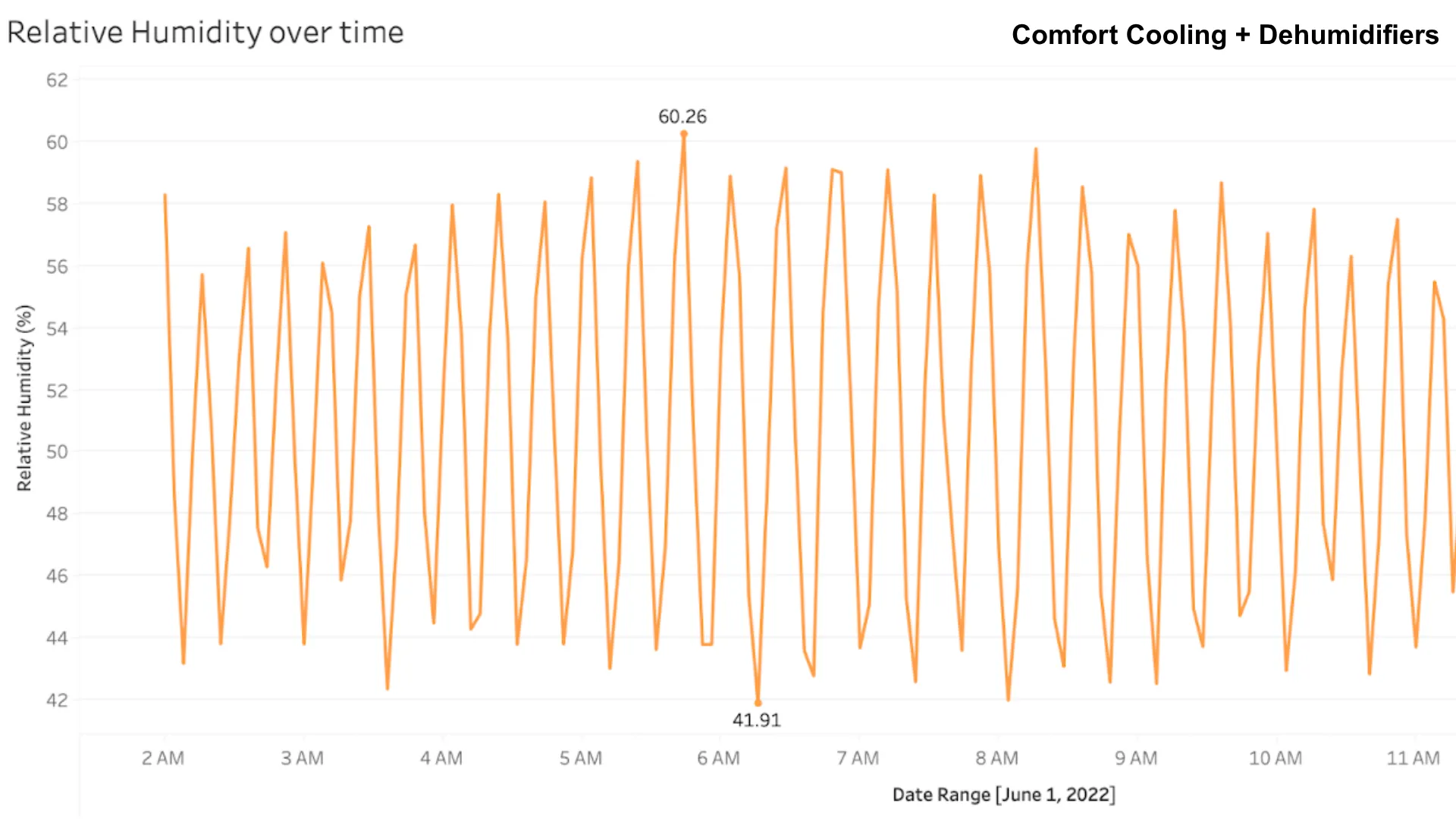

Split AC and dehumidifiers run independently. They have no unified control. As a result, temperature and humidity cannot stay in precise balance, and room conditions often fluctuate.

Dehumidifiers release heat during operation. This heat requires extra cooling, which creates a repeated cycle of cooling, dehumidification, and more cooling. Energy use increases clearly.

One room often needs many split AC units and dehumidifiers. The large number of devices means more cleaning, more servicing, and more points of failure.

Split AC units are often residential or light commercial grade. They break down more easily under long-term heavy load. They are not suitable for large-scale commercial cannabis cultivation.

Limitations of Variable Refrigerant Flow Systems for Grow Room HVAC

Many cannabis growers consider VRF systems as another option besides split air conditioners. They are widely used in commercial buildings and have advantages like low initial investment and flexible installation. But when applied to cannabis cultivation, where temperature and humidity are extremely sensitive, growers find that VRF cannot fully meet the actual needs.

VRF systems are designed for comfort buildings and focus on temperature control. Grow rooms require a lot of latent heat to handle. During the late flowering stage or lights-off periods, VRF cannot provide enough dehumidification, and extra dehumidifiers are needed.

When VRF and dehumidifiers work at the same time, the heat produced by dehumidification must be cooled again by VRF. This overlap increases energy consumption. For growers, it means higher electricity bills and operating costs.

VRF is reliable in office buildings. But in grow rooms with high humidity, heavy load, and year-round operation, there are many compressors, refrigerant lines, and indoor units. This increases maintenance work and the risk of larger failures. Long-term reliability often cannot meet the needs of commercial cannabis cultivation.

When cultivation scale expands, VRF faces limits in refrigerant pipe length, number of circuits, and design capacity. Expansion or adding redundancy is difficult. It is less flexible than integrated grow room HVAC systems.

Altaqua Is Truly Purpose-Built Cannabis Grow Room HVAC That Outperforms Traditional Solutions

In commercial cannabis cultivation, system energy consumption, maintenance costs, and environmental stability determine long-term operational success. Integrated grow room HVAC systems designed specifically for cultivation offer advantages in all of these areas.

According to the report from Anderson Porter Design , VRF systems consume the most power, while integrated grow room HVAC systems use the least—about 14% less than split systems and 16% less than VRF. Unlike VRF or split units that still need separate dehumidifiers, a purpose-built grow room HVAC for cannabis combines functions in one system, cutting overall energy consumption.

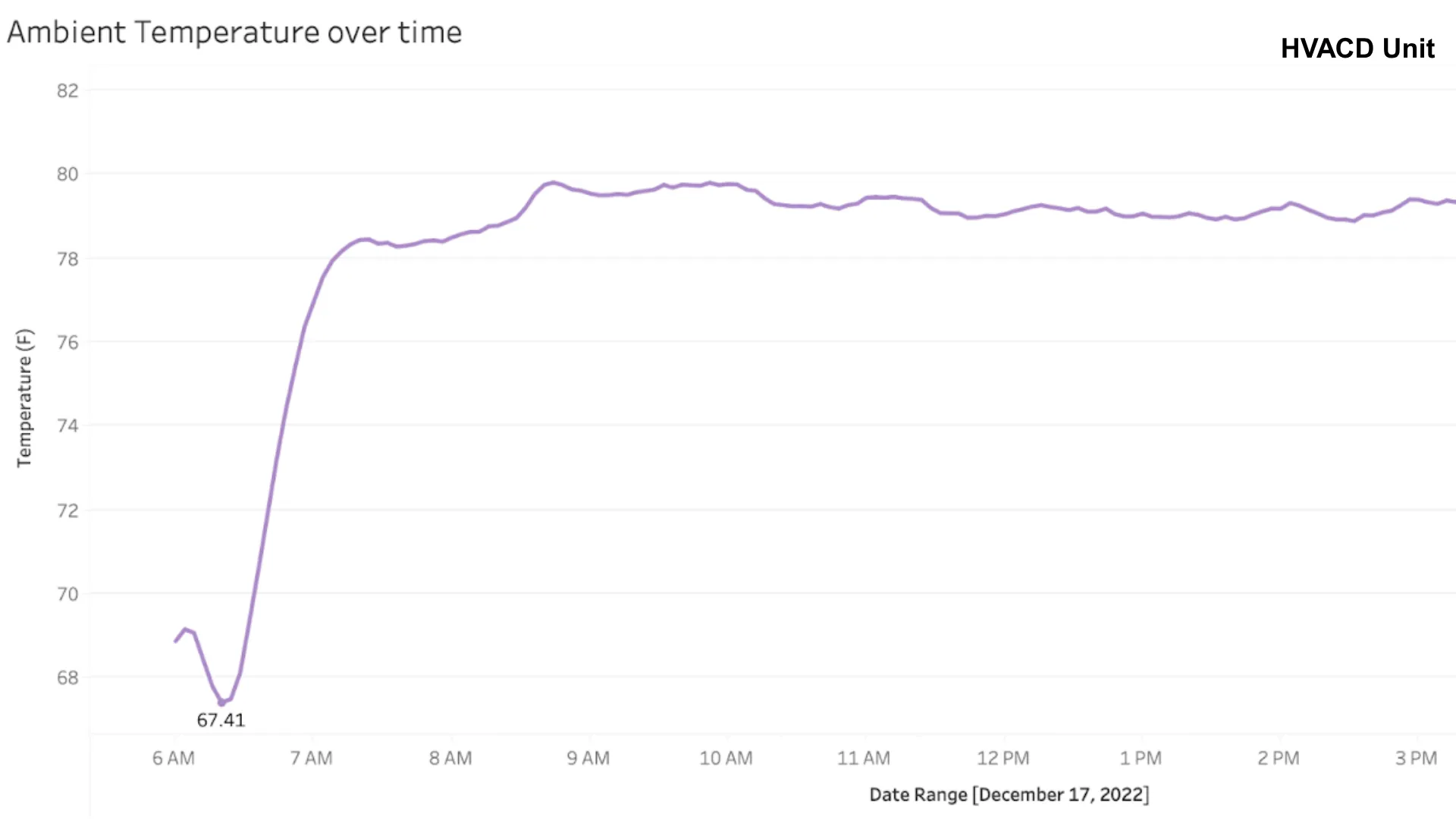

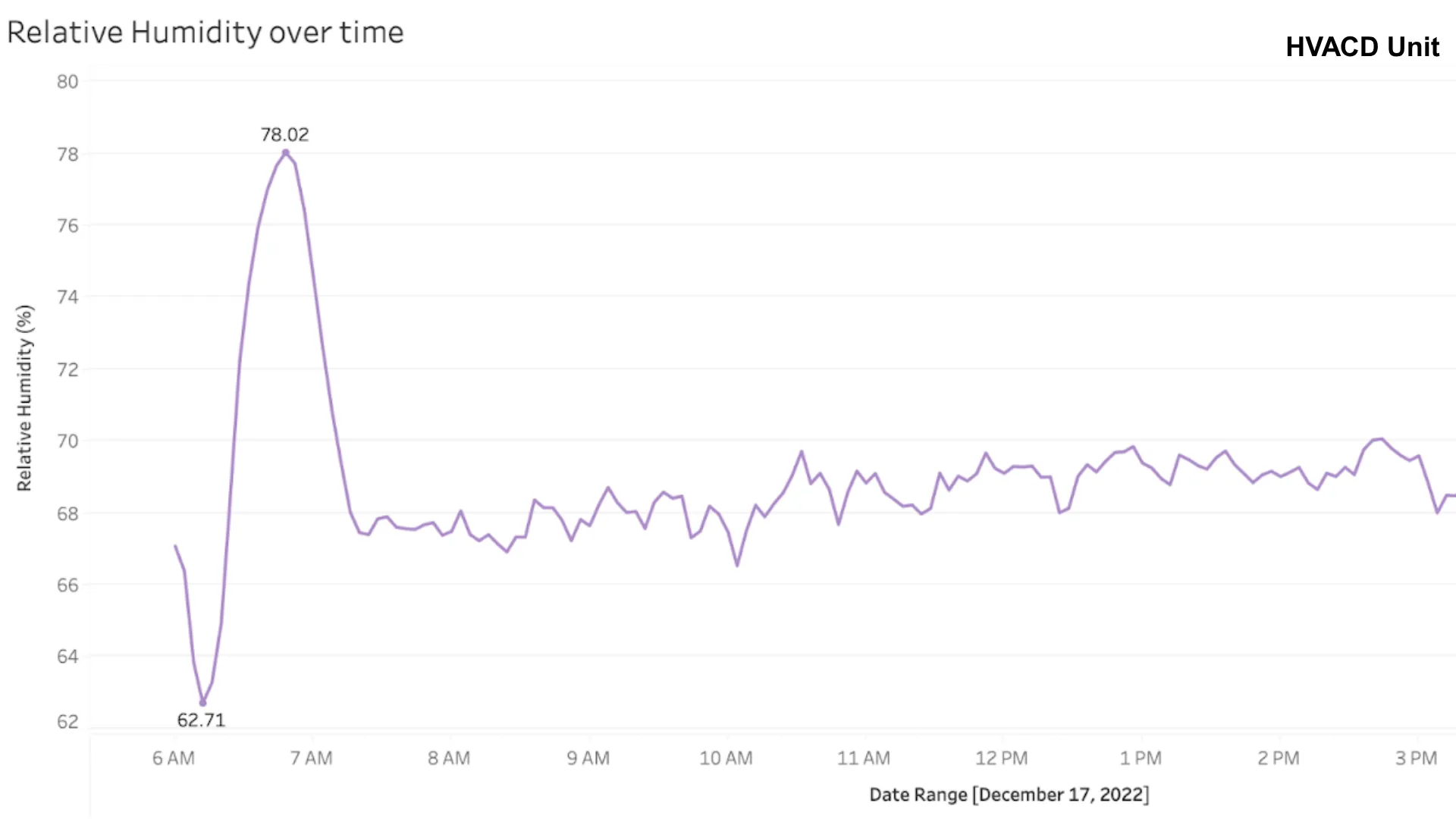

Performance is where the difference becomes most evident. Integrated grow room HVAC solutions process both sensible and latent heat simultaneously, keeping temperature within ±1°F and humidity within ±2.5%. Traditional AC plus dehumidifier setups fluctuate much more, often ±2.5°F and ±10% RH. For commercial cultivation, this stability of cannabis grow room HVAC directly improves plant health, yield, and consistency.

Altaqua grow room HVAC solutions are built according to industrial quality with every part constructed around the actual assumptions of cannabis growing. Our units are tested under return air dry bulb temperatures of 27℃ and relative humidity of 60%RH to achieve the reliable performance that will be delivered in your demanding grow room environment. For added confidence, the system is designed with built-in redundancy to prevent rapid wear on critical components and reduce downtime, yielding reduced maintenance costs over time.