In cannabis growing, every choice you make affects your final profit. Choosing the best grow room hvac systems is not just about buying equipment. It is an important investment. This investment decides how efficient your operation is and how much money you can make.

The right grow room HVAC solution should be your most reliable partner. It should not feel like a cost. Here are the top ten reasons to choose Altaqua for your grow room hvac setup. See how our smart devices and many years of HVAC know-how can help you succeed.

REASON #1

Precise Temperature and Humidity Control

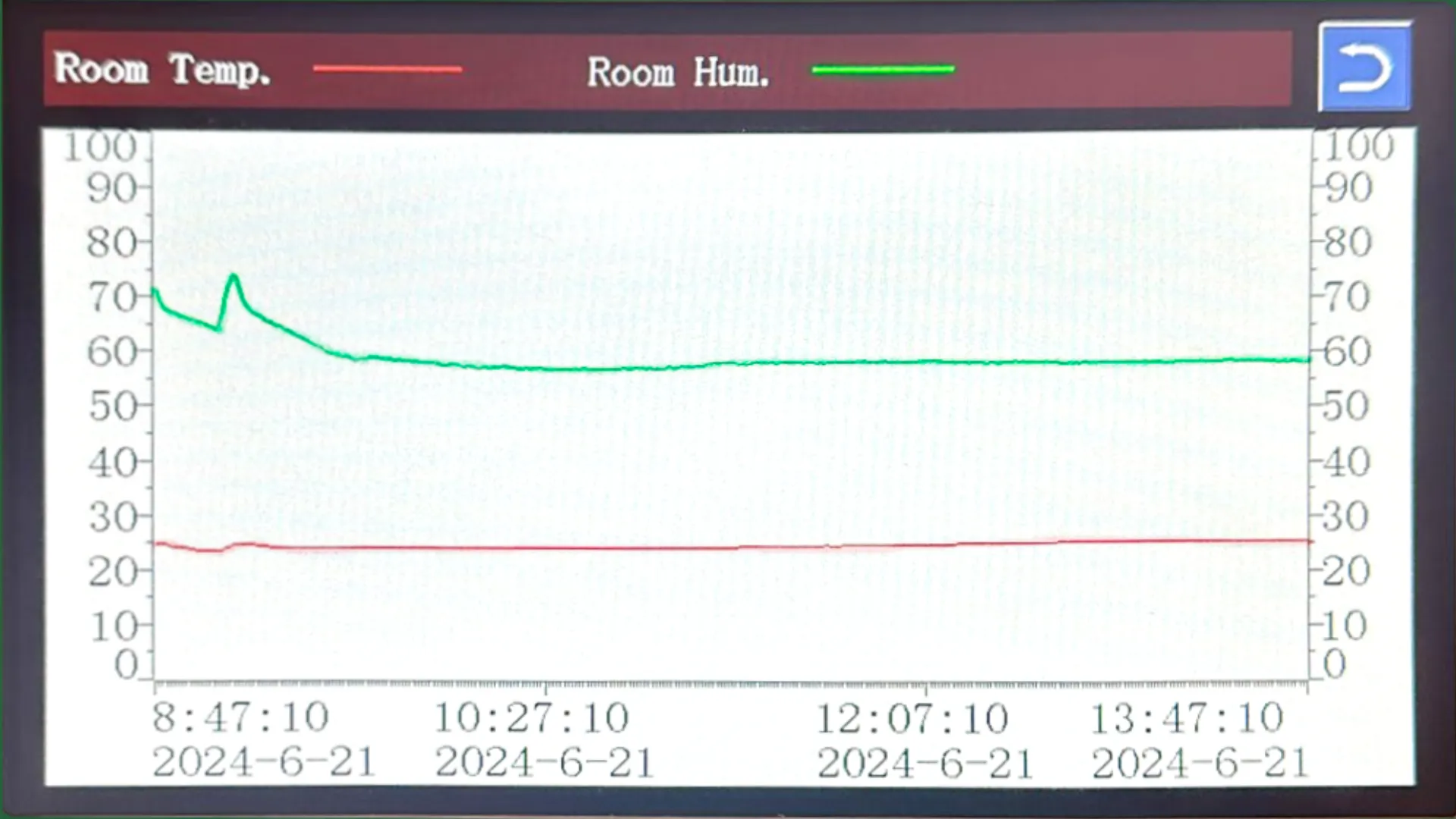

Altaqua grow room HVAC system delivers accurate climate control, maintaining temperature within ±0.5°C and dew point within ±1°C. It is able to auto-adjust using real-time data so that the conditions never get out of range.

Operation only ceases once temperature and humidity conditions are achieved, preventing overshoot and reducing stress on crops as environments change.

REASON #2

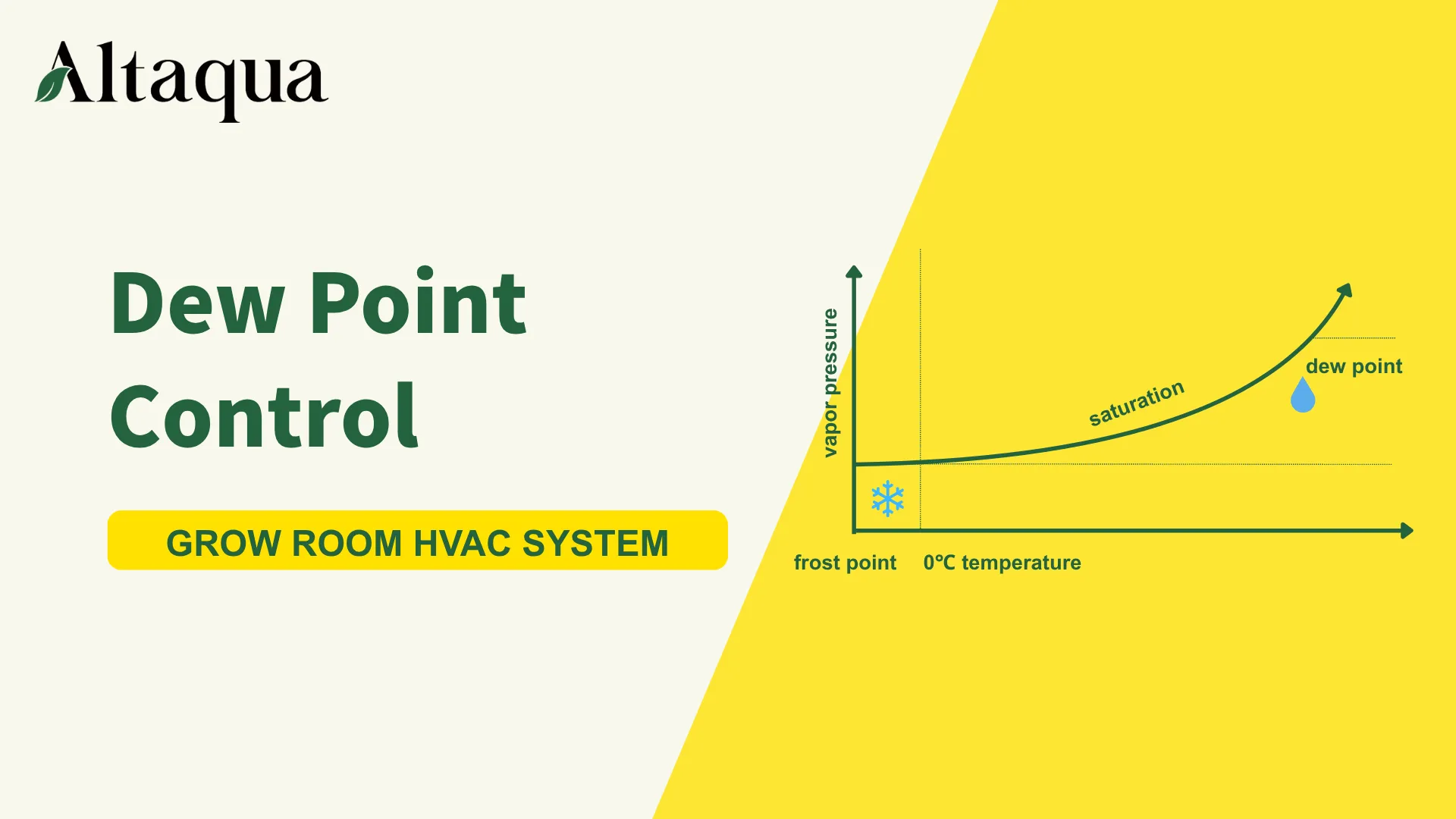

Dew Point Control for Accurate Dehumidification

Traditional humidity control can struggle with temperature changes. This often causes too much or too little dehumidification. Our HVAC system for grow rooms uses dew point control. This method focuses on the actual water vapor in the air. It doesn’t rely on temperature. So, it offers improved humidity control that is accurate and reliable. Growers can stop mold, boost flower quality, and increase yield.

REASON #3

E+E Precision Control and Superior Reliability

Our grow room HVAC system uses precise temperature and humidity sensors from E+E Elektronik in Austria. This keeps deviations within ±2.5% RH and ±0.3°C in the growing room. Small changes help growers keep stable environments during all growth stages. This leads to the best climate conditions, boosting yield and consistency.

REASON #4

Redundant Design for Avoiding Downtime

Our HVAC system features a built-in redundant design with multiple compressors and control circuits. If some modules fail, the others will still work. This keeps climate control running smoothly in grow room. For commercial growers, this means no downtime for equipment. There’s also no loss of temperature or humidity control. Plus, plants won’t get damaged, yields stay high, and flower quality remains strong.

REASON #5

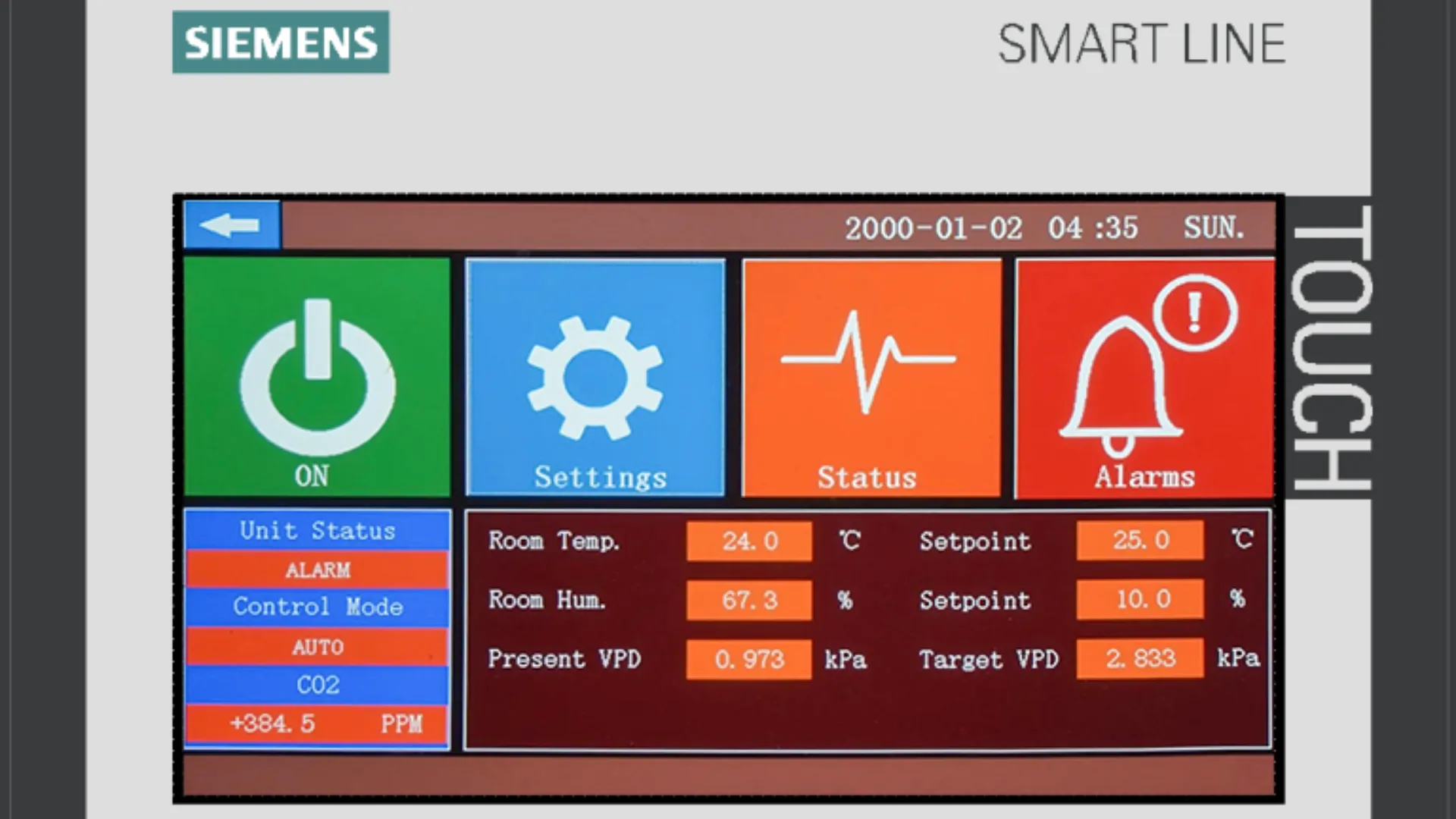

Siemens PLC Control Panel for User-Friendly Operation

Our grow room HVAC uses Siemens PLC and HMI technology. This ensures easy operation and flexible adjustments. Growers set their target temperature and humidity. The system then responds to changes in the environment. It automatically adjusts its operations to meet those targets. It reduces human errors, improves the CEA environment, and creates better conditions for flowers to grow. This results in higher quality.

REASON #6

WiFi Remote Monitoring and Control

Grow room HVAC by Altaqua offers WiFi connectivity. This allows for 24/7 remote access and real-time monitoring on mobile devices. You can check and change the temperature and humidity from anywhere in the world. Share real-time data when discussing cultivation parameters with your team or customers. This speeds up decision-making and boosts management efficiency. It also reduces errors and communication costs.

REASON #7

Modbus Integration for Easy and Centralized Management

Our grow room HVAC system can compatible with Modbus, making it possible to easily connect to existing facility management systems. Growers could control temperature, humidity and other important factors centrally instead of device by device. The manual workload is reduced and management efficiency enhanced.

REASON #8

Reliable EC Fan Motor Saves Energy Costs

Energy efficiency is critical for the best grow room hvac systems. So our system features EBM's GreenTech EC fans. These fans change airflow based on system pressure and return air temperature. It stops fluctuations caused by uneven airflow. It adjusts the fan speed based on actual needs. This cuts down on energy use and lowers costs. Plus, it helps save on energy bills. It also reduces fan overload, lowers equipment failure rates, and extends fan life. This cuts down on maintenance and replacement costs.

REASON #9

Work with Air Ducts for Even Air Distribution

Our system when incorporated with air ducts will mix and circulate air evenly within the grow space. This in turn avoids microclimates. It also eliminates hot and cold spots and pockets of stagnant, musty air. Using ducts, growers can distribute the airflow to stabilize the climate in the canopy. This results in consistent growth of the cannabis plant, leading to less opportunity for mold or stress, while enhancing quality present in the crop.

REASON #10

Famous International Brand Components

Altaqua cooperates with world-famous producers including Danfoss, Bsonyo, and ABB for the excellent components. This insures that our grow room hvac systems are created with high quality components made for longevity and performance.