5 Scenarios to Tell You Is Your HVAC System Really Accurately Controlling VPD?

Updated: April 8 ,2025 · 22 min read

In agricultural production, VPD not only affects the environmental control of individual growing chambers, but also plays a role in the wider ecosystem. Climate change in different regions may alter atmospheric humidity and temperature patterns, complicating VPD management. Higher VPD usually accelerates plant transpiration and promotes water evaporation, but if VPD is too high and water loss is too rapid, plants may close their stomata to minimise water loss, thus affecting photosynthesis and plant metabolism.

In addition, VPD affects plant water potential and balances water availability. Proper VPD maintains healthy water transport, promotes nutrient uptake, and ensures that the plant receives necessary passive nutrients. However, too low a VPD can lead to increased condensation, and an environment with too much humidity tends to induce mould growth and disease, increasing the plant's susceptibility to disease.

A good HVAC system should react to conditions. It must also expect and adapt in real time. In this blog, we'll dive into the top five challenges growers face in growing. We’ll explore how to manage sudden VPD changes and tackle winter dehumidification. This way, you can maintain stable VPD levels and boost your yields. Let's get started.

How to Crack the Challenge Posed by Dramatic Circadian VPD Fluctuations?

For greenhouse growing, VPD management is part of the environmental regulation of the greenhouse that affects energy balance and water use efficiency. If the VPD is too low, the greenhouse may require additional heating or dehumidification, while a high VPD may lead to a shortage of water supply and an increased need for irrigation. Therefore, precise control of VPD not only helps to optimise the growing environment for cannabis, but also reduces energy consumption and improves overall cultivation efficiency.

One issue that I'm sure many growers struggle with is diurnal VPD variations in the grow room. Many growers ask why VPD is well managed during the day. At night, though, it often gets out of control, like a rebellious child.

Circadian VPD Fluctuations Pose a Challenge

Keeping a stable VPD isn't just about setting temperature and humidity. Plants go through different physiological states in the day and night.

Daytime: the plant photosynthesizes actively. It releases 500 mL of water per square meter each hour through its stomata.

At night: stomata are closed and transpiration is reduced by 95 per cent.

Controlling the plant with fixed settings is like forcing it to sprint and then sleep. Studies show that if VPD changes more than 0.8 kPa every 12 hours, cannabis THC levels can drop by 18%. Also, disease rates can rise by 40%.

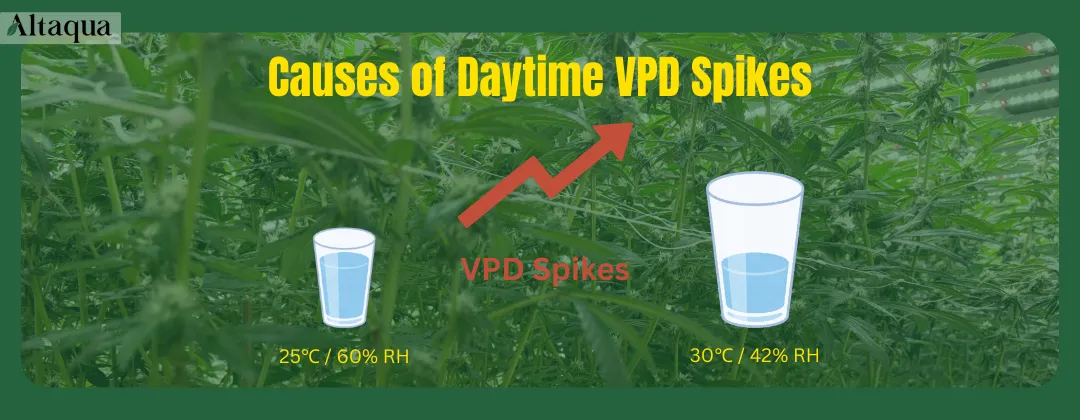

Causes of Daytime VPD Spikes

VPD shows how much the air inside a cannabis grow room "wants" to be dry. It controls how water moves through the plant and affects photosynthesis. It also plays a hidden role in how cannabis uses water during photosynthesis.

During the day, as light increases, cannabis starts photosynthesis and transpiration. This causes more water vapor in the air. However, relative humidity may not increase as expected. As temperatures rise quickly, like with a high-temperature growth strategy, the air can hold more water. For every 1°C increase in temperature, the air’s maximum water-holding capacity grows by about 7%.

Think of it like a cup of water suddenly becoming much bigger. The amount of water stays the same, but there is more empty space. If you start with a full glass at 25°C and 60% RH, then switch it for a larger one at 30°C without adding water, the relative humidity will drop to about 42%. VPD will rise at a rapid pace.

Some cannabis growers may believe that raising the temperature will speed up growth. But, when the temperature increases from 28°C to 32°C, the air’s water-holding capacity rises by 33%. If the humidity stays at 60% RH, the VPD will jump from 1.1 kPa to 1.8 kPa. This is like making workers do intense labor in hot conditions without giving them water. It may seem like they are working harder, but in reality, it harms performance. In the end, this could reduce net photosynthetic efficiency by 22%.

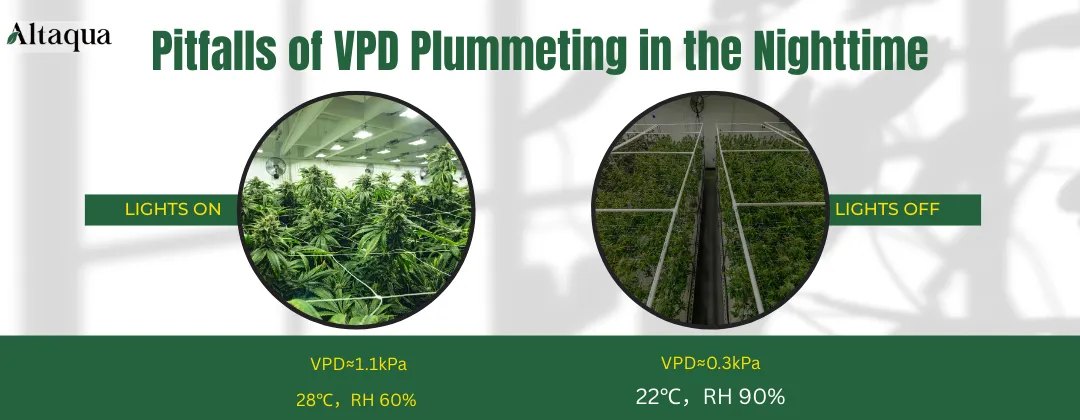

Pitfalls of VPD Plummeting in the Nighttime

Many growers don't know that temperature changes can greatly impact VPD. This is especially true at night. When the lights go out, many cannabis growers wonder why humidity in the grow room increase so much. This is due to the ‘shrinkage effect’ of falling temperatures. For each 1°C drop in temperature, the air's maximum water storage capacity falls about 7%. Air that is like a big bucket of water during the day (28°C/60%RH, VPD≈1.1kPa) becomes a small glass of water at night (22°C). If the actual water vapor stays the same, the water table line (RH) goes above 90%. Then, the VPD drops to 0.3 kPa.

At night, when the grow room lights turn off, the cannabis experiences darkness. During this time, the stomata close. As a result, transpiration drops by 80-95%. The plants stop using water vapor, so humidity starts to rise in the room. If the VPD drops below 0.3 kPa, the transpiration pull weakens. This means the roots can't move water and nutrients up. As a result, leaf tips might ‘spit water.’

Some cannabis growers might turn off their ventilation systems at night to save energy. This traps moisture inside and keeps it from escaping. The grow room can turn into a ‘steam bath.’ If the RH goes over 90 percent for four hours, water forms on the cannabis leaves. This film closes the stomata, reducing carbon dioxide uptake by 60 percent. Even with extra light, photosynthesis efficiency drops to below 30 percent of daytime levels.

The Problem of Lagging Regulation by Traditional Equipment

Many cannabis growers see the need to manage VPDs. But in practice, it often doesn't work well. Why is that? Some cannabis growers use split temperature and humidity controllers and mechanical sensors. However, these tools have flaws. They struggle to accurately control the VPD in grow rooms.

Inability to Respond to VPD Changes in Real Time

Traditional temperature and humidity controllers work separately. When the temperature rises, the system may cool the room but not adjust the humidity. This can cause VPD spikes in the grow room.

Mechanical sensors only update data slowly. They can’t sense changes right away, causing delays in response. Split controllers can take 15-30 minutes to react. By the time they detect a VPD issue, plants may have been stressed for 400-600 seconds. No cannabis grower wants this to happen.

Opaque Data Makes It Difficult to Optimize VPD Control

Many conventional devices struggle with accurate VPD detection. Cannabis growers often rely on temperature and humidity data for rough estimates. This makes it hard to know if VPD is in the ideal range. Mechanical sensors can have errors of up to ±5% RH/±1.5°C. For example, if the true VPD is 1.2 kPa, the monitored data might show between 0.9 and 1.5 kPa. This leads to a high error rate of ±25%. Also, traditional devices don't record data smartly. Growers struggle to optimize their environmental conditions without analyzing historical data. Long-term trends are key for success.

Energy Consumption of Passive Dehumidification

Some cannabis cultivation rooms use passive dehumidification. This often means relying on air conditioners to cool the air and reduce humidity. However, this method isn't very energy-efficient. Air conditioners mainly cool air, not dehumidify it well. They must run constantly to lower the temperature below the dew point. This causes water vapor to condense, but it also uses a lot of electricity. Plus, it can make the room too cold, harming cannabis growth and even causing cold damage. Sometimes, growers need extra heating to keep the right temperature. This adds more energy costs and waste.

Dynamic Balancing System Provides Precise VPD

Traditional methods for controlling temperature and humidity usually rely on one method. This can lead to big changes in VPD throughout the day. Many cannabis growers wonder why VPD isn’t stable but often overlook the need for a smarter, balanced system. To manage VPD well, growers should use real-time monitoring. They can adjust their equipment based on data feedback and smart connections.

Intelligent Temperature and Humidity Joint Control Algorithm

Our Altaqua Grow Room HVAC system moves beyond traditional single-pass regulation. It uses smart algorithms to control temperature and humidity by considering their relationships. The system also looks at temperature, humidity, and VPD. It keeps VPD stable with multi-dimensional regulation. for example:

When the VPD is high, like on hot days, the air holds more water. This causes lower relative humidity. In this case, the system will increase humidity and lower the temperature. This keeps the VPD from rising fast. It also stops plants from losing too much water through transpiration.

When the VPD is too low, like at night when it gets colder and more humid, the system acts quickly. It lowers the humidity and raises the temperature. This helps stop the "shrinking effect" that causes water vapor to get stuck. If not, it can lead to "spitting water" on leaves or even mold growth.

This multi-variable control method is better than fixed temperature and humidity settings. It allows for precise environmental regulation. This reduces big changes in VPD and helps plants grow more consistently.

Real-Time VPD Monitoring and Feedback to Ensure Transparent and Controllable Data

Our Altaqua Grow Room HVAC system features an Intelligent Dynamic Balancing System. This data updates in real time and connects to a cloud-based processing system.

Key benefits include:

Data visualization: Growers can check VPD status anytime on phones, computers, or other devices. This ensures a controlled and clear growing environment.

Real-time alarm system: The VPD monitor tracks the VPD value in the grow room. This helps growers see changes in the indoor environment. They can then make quick adjustments when the vapour pressure difference value changes.

Historical Data Analysis and Optimization: The smart system creates detailed historical reports. Growers can use these reports to enhance their environmental strategies. This helps them grow more efficiently in the future.

This active regulation mode cuts down on human intervention. It also greatly boosts the environmental stability of the grow room. As a result, it helps achieve higher yields and better crop quality.

|

Dynamic equilibrium systems vs. traditional regulation |

|

|

|---|---|---|

|

Functionality |

Conventional temperature and humidity control |

Intelligent Dynamic Balance System |

|

VPD Control Method |

Dependent on fixed settings, not dynamically adjustable |

Intelligent joint control algorithm, dynamic adjustment of temperature and humidity |

|

Energy Management |

High energy consumption, which may result in hot and cold |

Precise control to reduce energy waste |

|

Data Monitoring |

Reliance on manual testing and lack of historical data |

Real-time monitoring + data visualisation + reporting and analysis |

|

System Response Speed |

Requires manual intervention, adjustment lag |

Automatic feedback for fast VPD adjustment |

The Intelligent Dynamic Balance System enhances control of the planting environment. It also lowers energy use, boosts yields, and improves quality. This makes it a crucial tool for efficient planting and environmental management.

How Do HVAC Systems Keep VPD Stable When Plants Are Growing Rapidly?

Another challenge for cannabis growers occurs during the fast-growing phase. At this time, the plant’s metabolic rate peaks. The grow room’s environmental control becomes tricky. Growers must balance several factors to reach the right VPD level.

Challenges of Managing VPD During the Growing Season

During cannabis growth, especially when nutrients peak, managing VPD feels like "lighting a candle in a hurricane." You aim to keep photosynthesis strong while dodging environmental chaos. At this stage, the plant acts like a bioreactor running at full speed.

● Metabolic rate can be 4-6 times that of the seedling stage

● The daily water consumption of a single plant exceeds 3-5 litres.

● stomatal oscillations of up to 0.2 Hz (5 openings and closings per second).

VPD control is a precise race against plant physiology. Data shows that if VPD goes above 0.5 kPa per hour during growth, cannabis synthesis of secondary metabolites drops. This decline is between 18% and 22%.

The best VPD range is 0.8 to 1.2 kPa. This helps plants transpire and exchange gases well. It also prevents too much water loss and high humidity, which can lead to diseases. During flowering, you can raise the VPD to 1.2-1.5 kPa. This supports flower growth and boosts yields.

|

Growing Period |

Ideal Temperature |

Ideal Humidity |

Ideal VPD |

|---|---|---|---|

|

Vegetative Stage |

71-82℉(22-28℃)with light on 64-75℉(17-23℃)with light off |

40-70%RH |

0.8-1.2 kpa |

|

Flowering Stage |

68-79℉(20-26℃)with light on 59-70℉(15-21℃)with light off |

40-50%RH |

1.2-1.6 kpa |

|

Late Flowering Stage |

64-75℉(18-24℃)with light on 59-66.2℉(15-19℃)with light off |

35-50%RH |

1.2-1.6 kpa |

Plant Transpiration Increases and Humidity Rises Dramatically

As cannabis grows faster, their transpiration increases significantly. Transpiration is when a plant takes in water through its roots. It then releases this water into the air via small openings called stomata on the leaves. This process includes evaporating a lot of water into the air. This raises humidity quickly in the growing chamber.

VPD is key here. Lower VPD slows water diffusion from leaf surfaces. This can block transpiration. Higher VPD helps water transport, but if it’s too high or too low, it can cause rapid water loss. This may stress the plant. If humidity is too high, it may lead to a decrease in VPD, reducing the ability of cannabis to transport water and even increasing the risk of disease.

The transpiration rate of cannabis can reach 12L/m²/day. This means each plant releases 200-300mL of water hourly. It also adds 3.5g/m³ of water vapor to the air every minute. When the VPD drops below 0.8 kPa, the transpiration rate goes down. This reduces the root system's ability to absorb water. As a result, water-logged lesions can form on the bottom leaves, affecting nutrient transport. If VPD is over 1.5 kPa, transpiration becomes too strong. Plants may lose water too fast. This can cause leaf curling, lower photosynthesis, and even impact the final yield.

If humidity isn't managed quickly, problems arise. When the canopy's humidity goes over 75% RH, a thin film of water will appear on the edges of cannabis leaves. This causes stomatal conductance to drop by 30% and makes CO₂ diffusion resistance rise by 2.3 times. Even with the perfect light, the net photosynthesis rate drops by 25%. It’s like an engine with oil, but a clogged exhaust pipe.

Risk of Abnormal Stomatal Opening and Closing

Dramatic changes in VPD can impact how plant stomata open and close. When VPD exceeds 1.5 kPa, stomatal opening drops sharply from 0.8 μm to 0.2 μm. This leads to a 72% decrease in transpiration pull and a fall in root water uptake from 4 mL/min to 0.7 mL/min. This is equivalent to putting a respiratory mask on the plant - reducing water loss but stifling vital activities.

When VPD is below 0.4 kPa, guard cell potassium ion pumps fail. This leads to messed up opening and closing rhythms. Stomata even close when light is on. Surprisingly, there’s a transpiration peak at 3-5 am, which is unusual since it should be below 10% of daytime levels.

Misconceptions About Conventional Regulation

Many cannabis growers face big challenges. Still, they stick to old methods for managing the environment. They use fixed humidity settings, simple PID controllers, and set wind speed fans. However, these methods can’t adjust well to the changing needs of cannabis as it grows. This can even make VPD stability worse.

Static Regulation Cannot Cope With Dynamic Demands

Many grow room HVAC systems rely on a fixed set-point control model. This means a set humidity or temperature triggers humidification or dehumidification equipment. However, cannabis transpiration varies daily or even hourly. Fixed set-point controls can't adapt well and lead to several issues:

● When transpiration increases, dehumidification may lag. This can cause a quick spike in humidity and a sudden drop in VPD.

● Excessive dehumidification makes humidity drop too fast. This causes VPD to rise quickly, putting the plant in "stress mode."

● The system’s hysteresis causes the VPD to swing between too high and too low, instead of staying stable.

Measuring VPD in real time is crucial for effective management. Use the leaf vapor pressure deficit calculator to find the vapor pressure difference between the leaf and the air. This helps growers check if VPD is within recommended levels. With PulseOne Pro VPD calculators or charts, you can easily see VPD values. These values change with different temperature and humidity conditions. This way, you avoid relying too much on one control point.

Limitations of Single-Variable Regulation

Some older systems control temperature and humidity separately. They focus on one factor at a time, like just temperature or just humidity. This can ignore the balance of VPD. For instance, if a system controls only temperature, it might cause big changes in humidity. On the other hand, focusing only on humidity can lead to temperature swings. This single-variable approach doesn't meet the complex needs of cannabis. It often leads to unstable VPD, making it hard for growers to manage the environment properly.

To manage VPD effectively, use a scientific approach. First, analyze data with a psychrometric chart. This helps you find the air's saturated vapor pressure and the actual vapor pressure around you.

Growers can track leaf temperatures using pd measurements and infrared thermometers. This helps them collect accurate VPD data. Then, they can consult reference charts to adjust temperature and humidity quickly. This keeps VPD at the ideal level.

Shock-Free Transition Technology Avoids VPD Mutations

In many traditional HVAC systems, control often depends on set-point triggering. This means that equipment turns on or off when temperature or humidity hits a specific limit. For example, if humidity reaches 70% RH, a dehumidifier turns on at full power to quickly lower it. Similarly, when the temperature drops to 20°C, a heating unit activates to raise the temperature fast.

Our Altaqua Grow Room HVAC systems adjust their speeds smoothly. Unlike traditional fixed-speed systems, which only turn on and off, they provide better control. This helps prevent sudden starts or stops. For instance:

● Dehumidification modules can adjust power slowly based on humidity trends. This way, they don’t just run at maximum power all at once.

● Fans let users change the air speed easily. This way, they avoid fixed air volume. It ensures smooth air flow and stops sudden local VPD changes.

● Heating or cooling equipment can gradually adjust power. This helps prevent sudden temperature changes.

If the humidity in the grow room goes up from 60% RH to 65% RH, a conventional system might quickly turn on the dehumidifier. This can make the humidity drop back to 60% RH fast, which suddenly raises the VPD. As a result, plants lose more water.

On the other hand, a system with inverter control slowly ramps up the dehumidifier power. For instance, it might increase by 0.5 percent RH per minute. This approach allows for a smoother change in the VPD curve.

How to Crack the Problem of Low VPD in Winter With Low Temperature and High Humidity?

One of the main challenges cannabis growers face during the winter months is how to maintain an ideal vapour pressure differential (VPD) in cold temperatures and high humidity. Cold temperatures in winter environments reduce the saturated water vapour pressure of the air, while high humidity further compresses the room for VPD regulation, making it difficult for growers to find the right balance.

VPD is not just a simple combination of humidity and temperature, but a key climate parameter that is directly reflective of the state of moisture exchange between the air and the plant. By using VPD as a guide, growers can adjust environmental conditions more precisely to optimise the transpiration rate of plants.

Long-term trends in climate change and short-term weather fluctuations can affect VPD management. For example, global climate predictors indicate that the frequency of extreme winter weather events is increasing, which means growers must respond to more dramatic temperature and humidity changes. Analysing the external environment using kilometre resolution climate data can help growers better predict trends in VPD and take preventative measures.

VPD is not a fixed target value, but is influenced by the dynamics of the climate environment. It is closely related to relative humidity. When the temperature drops, relative humidity rises and VPD decreases; conversely, when the temperature rises and the air can hold more water vapour, relative humidity drops and VPD increases. Therefore, understanding VPD is critical to accurately regulating the growing environment.

Fluctuations in outdoor temperature and humidity directly affect indoor air conditions, making VPD management even more complex. For example, during a cold snap, room temperatures can be difficult to maintain and VPD fluctuates dramatically, placing additional stress on cannabis growing conditions. In this case, VPD is not only a parameter to measure the state of the environment, but also a tool to proactively manage the growth of the plant. By monitoring and regulating in real time, growers can maintain optimal growth of cannabis in extreme climatic conditions.

Challenges of VPD Control in Winter

Managing VPD in winter is tough because of humidity and low temperatures. Cold outside air makes it hard to vent water vapor in the grow room. This leads to high humidity, which disrupts cannabis growth. Also, low temperatures reduce how well dehumidifiers work. Traditional methods often struggle to solve this issue.VPD is usually low in winter. This means less evaporation and water transport. If low VPD lasts too long, it can disrupt how plants open and close their stomata. This affects CO₂ uptake and reduces photosynthesis efficiency.

Dehumidification Equipment Efficiency Dips in Low Temperatures

The moisture content, or absolute humidity, of air goes down as temperature drops. This means there's less water vapor in cooler air. Conventional dehumidifiers cool the air below the dew point to condense and remove water vapor. But when temperatures are low, there's less water vapor to work with. This makes dehumidification less efficient. It’s harder to lower relative humidity effectively.

In this case, VPD regulation relies on dehumidification capacity. It also needs a warming strategy. This helps raise the air's saturated water vapor pressure. The goal is to keep VPD in the right range, usually between 1.0 and 1.2 kPa. So, in winter, controlling temperature and humidity is key. A precise approach is better than just one way to dehumidify.

Stagnant Humidity Leads to Impaired Plant Health

High winter humidity lowers VPD. This means cannabis transpires less, making it hard to absorb water and nutrients. As a result, photosynthesis is less efficient. Moisture lingers around the roots for too long, harming root respiration and increasing the risk of root rot. High humidity also promotes mould, powdery mildew, and grey mould. This makes pest and disease control harder.

Low VPD affects cell expansion, inhibiting plant elongation and growth, leading to a decrease in overall yield.A drop in VPD changes the grow room's microclimate. For instance, high humidity in the canopy forms a "high humidity barrier." This barrier stops water vapor from diffusing and keeps the leaf surface wetter. It impacts stomatal conductance and may worsen disease development.

Shortcomings of Traditional Equipment on the Market

Standard rotor dehumidifiers and resistive heaters work well at room temperature. But, they have trouble in cold conditions. Here are some common issues they face:

Standard Dehumidifiers Difficult to Handle Cold Temperatures

Condensing dehumidifiers cool air using the evaporator. This cooling makes water vapor turn into droplets, which are then released. However, when temperatures fall below 0°C, moisture can freeze on the evaporator. Frost blocks air circulation and lowers heat transfer efficiency. It also disrupts the dehumidifier's normal function. This can trigger defrost mode, which raises energy use and lowers dehumidification capacity.

High Energy Consumption but Limited Dehumidification Effect

Conventional rotor dehumidifiers need hot air to dry out after soaking up moisture. If the temperature is low and there's no extra heat, they can't regenerate well. This reduces their ability to keep taking in moisture. Also, they use a lot of extra energy to stay at the right temperature, which worsens energy use issues.

Some dehumidification methods in cold environments use resistive heaters. They raise air temperature, making humid air easier to condense or adsorb. However, this approach is indirect and consumes a lot of energy. It can help with low-temperature dehumidification, but its energy efficiency ratio (COP) is low. This is because it uses a lot of electricity to heat the air directly. So, it’s not suitable for large-scale farming or industrial use.

Distortion of Low-Temperature Data Collection

Low temperatures can impact how well temperature and humidity sensors work. Some sensors give inaccurate readings when it’s cold. This affects the dehumidification system's control. Incorrect humidity data in VPD (vapor pressure difference) management can lead to poor regulation strategies. The system has trouble keeping the right humidity levels when it's cold and humid. This can hurt plant growth.

Our Low-Temperature Dehumidification Solutions

Our Altaqua Grow Room HVAC systems solve VPD issues. These problems occur in winter when temperatures drop and humidity rises. They provide efficient, low-temperature dehumidification. This keeps VPD levels stable, promoting healthy plant growth even in tough conditions.

Specialised Dehumidification Modules for Low Temperatures

In low-temperature settings, regular dehumidifiers often struggle with frost and poor energy use. Our low-temp dehumidification module solves these issues. It uses smart heat exchanger design and advanced condensation technology. This prevents frost on the coil. This boosts dehumidification in cold conditions.

The intelligent defrosting system adjusts the defrost cycle based on temperature and humidity. This prevents frequent stops, keeping the dehumidification process smooth. Plus, the module features an inverter compressor and EC fan. They manage air flow and cooling power. This boosts dehumidification and reduces energy use.

Our dehumidification module performs well in temperatures below 5°C. It keeps the right VPD in the grow room, so plants grow healthy.

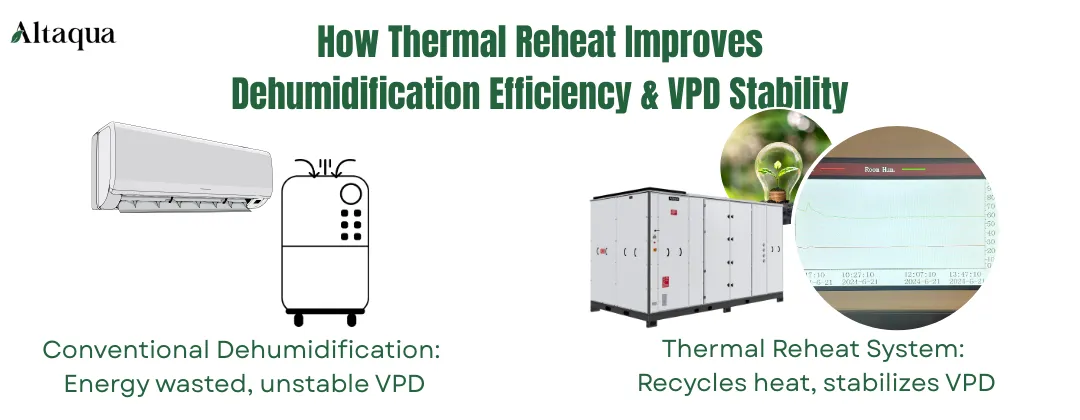

Thermal Reheat Function

To boost low-temperature dehumidification, we offer a hot gas reheat function. This system captures heat from dehumidification and uses it for room heating. This improves the overall energy efficiency ratio (COP).

An intelligent control system optimizes heat distribution. This keeps temperature and humidity stable, preventing big changes in VPD. Compared to traditional methods, our system cuts energy use by over 30%. This cuts grow room costs. It also provides growers with stable, energy-efficient VPD control.

This technology ensures steady dehumidification, even in cold winter months. It also reduces energy waste, helping growers manage their environment more efficiently.

How to Achieve 3D Precise VPD Regulation With High-Density Implantation?

Some cannabis growers plant closely to increase profits. However, they overlook a key issue: overlapping leaves restrict air circulation. This can lead to an uncontrolled microenvironment. Consequently, they often struggle to manage VPD.

Risk of Uncontrolled Microenvironment

In high-density growing conditions, air flow in the growing room is limited. This restriction can lead to uneven temperature and humidity levels. If these variations aren’t managed well, it can cause humidity to rise and temperature differences to grow. This makes it harder to control VPD in the entire room. These issues can hurt cannabis growth. They may cause diseases and affect yield and quality.

Localised Humidity Build-Up Affects the Overall Environment

In crowded growing spaces, air flow slows down because of dense leaf coverage. This makes it hard for water to evaporate fast after transpiration. As a result, humidity rises in some areas. This uneven humidity can hurt cannabis transpiration and may lead to mould and diseases. These issues can disrupt the whole growing environment.

Significant Difference in Temperature and Humidity Between the Upper and Lower Floors

Hot air in the growing room rises, leaving cooler air below. This lower level has higher humidity because of poor air circulation. The big gap in temperature and humidity can make plant growth uneven. It affects how plants transpire and perform photosynthesis. Over time, these differences can stress plants. This can lower yields and raise the chance of disease.

Limitations of Traditional Air Supply Systems

Many growers use old methods for air circulation. They often rely on axial flow blowers or single-point sensors to check temperature and humidity. But these systems have issues in high-density growing areas. They struggle to provide precise VPD regulation. A single top air supply can’t evenly cover the entire space. Also, data from single-point sensors often fails to show the real conditions. This makes it hard to spot and fix microenvironment problems quickly.

A Single Top Air Supply Cannot Cover the Whole Environment

Axial flow fans often use top air supply. However, this method does not cover the entire planting space evenly. The cascading leaves block airflow, making it hard for air to reach lower plants. This leads to restricted airflow and humidity build-up below. High humidity can disrupt VPD stability and raise disease risk.

Micro-Environmental Anomalies Are Difficult to Detect and Correct in Time

Traditional monitoring of grow environments often uses single-point sensors. These sensors fail to capture the temperature and humidity spread in the space. Data from one location might not reflect the entire environment. Conditions can change greatly in different areas. This can cause hidden problems that don’t get fixed fast, affecting growth results.

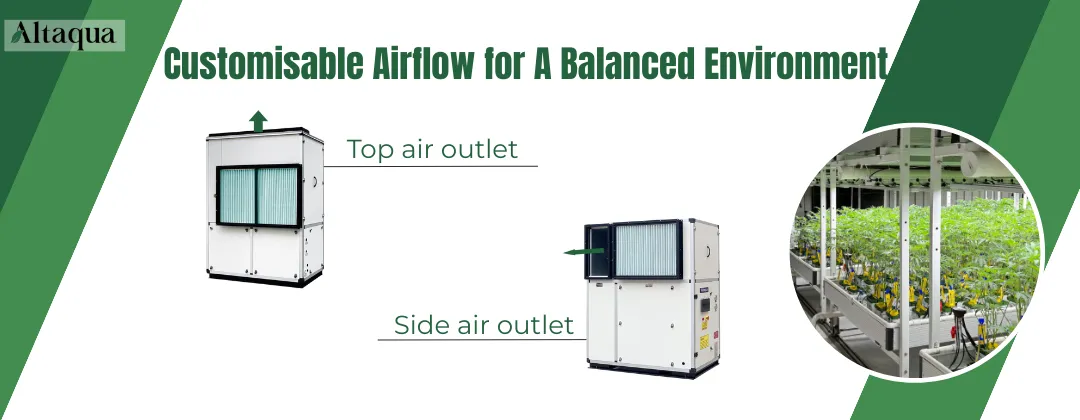

Customisable Airflow for A Balanced Environment

Our Altaqua Grow Room HVAC systems solve air circulation problems in tight growing spaces. They use air supply flange technology. This design allows for precise airflow distribution, which helps optimize VPD control. The air supply flange improves airflow and lets you customize your grow room. This ensures consistent temperature and humidity across different areas.

By managing airflow effectively, it covers the entire growing area evenly. The air supply flange is better than traditional top air systems. It controls wind speed and direction with greater precision. This creates balanced airflow between upper and lower levels. It also reduces local humidity buildup and keeps VPD control stable.

How Can HVAC Systems Respond Intelligently to VPD Shocks After Irrigation?

Irrigation is crucial for healthy cannabis growth during cultivation. However, it can cause a quick rise in humidity. This change may disrupt the VPD, which affects transpiration and nutrient uptake. When the HVAC system can’t keep up, it makes the microenvironment unstable. This increases the risk of disease.

Humidity Challenges From Irrigation

Each irrigation sends a lot of water into the air. This quickly raises humidity and drops VPD. These changes can last from minutes to hours and can hurt plant transpiration. If humidity isn't controlled soon, the whole growing environment might be at risk.

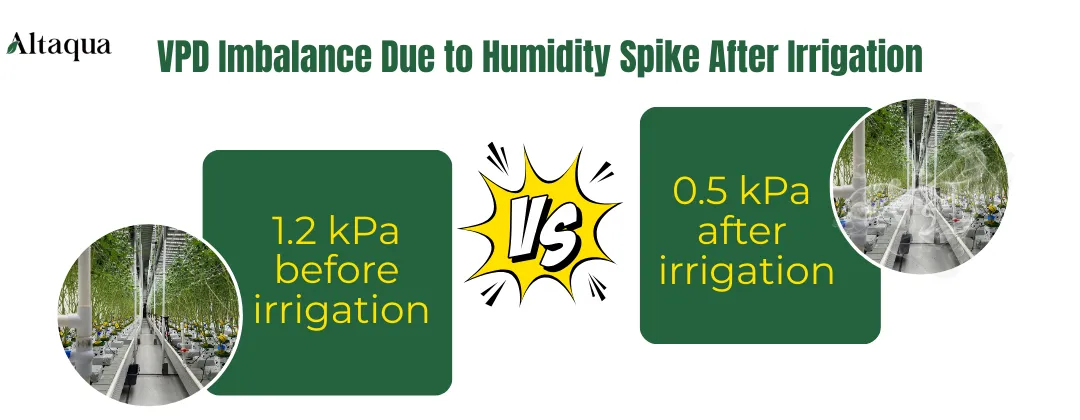

VPD Imbalance Due to Humidity Spike After Irrigation

After irrigation, water evaporates from leaves, and air humidity rises. This causes a quick drop in VPD values. This change affects how plants transpire. As a result, they take up less water and nutrients, which harms their growth. Also, big changes in humidity can cause mould to grow, raising the risk of diseases.

Uneven Local Humidity

After irrigation, humidity levels can vary greatly in the growing area. Some spots may be very humid, while others stay dry. Uneven moisture can disrupt the VPD. This makes the growing environment more complex. Conventional HVAC systems struggle to regulate humidity properly. This causes high humidity in some places, which raises disease risks. Meanwhile, other areas don’t have enough water for proper transpiration.

Shortcomings of Current Market Solutions

Traditional HVAC controls, like timer systems and basic dehumidification valves, can’t give precise control after irrigation. They often stick to fixed operation modes. They don’t make smart adjustments based on real-time feedback. This can lead to slow responses or excessive dehumidification. Both hurt growth efficiency and energy use.

Inability to Accurately Identify Irrigation Events and Lagging Response Time

Most traditional HVAC systems use timers or manual controls for dehumidification. They don’t automatically detect irrigation events. Humidity changes can delay responses. This leads to slow VPD recovery and affects plant growth. Also, fixed-time modes can lead to unnecessary dehumidification, which increases energy use.

Excessive Dehumidification Leads to Increased Energy Consumption and Equipment Losses

Without clear rules, some HVAC systems may over-dehumidify after irrigation. This can lead to low humidity levels, causing high VPD for a short time. As a result, plant transpiration can be affected. Using the equipment at a high load for too long uses more energy. It also wears out the dehumidification system faster. This shortens the equipment's lifespan and raises maintenance costs.

Intelligent Solutions

The smart HVAC system uses advanced sensors to fix the VPD imbalance. This issue happens when humidity quickly rises after watering. It also employs a phased humidity control strategy. It automatically detects irrigation events and adjusts dehumidification. This keeps VPD stable, cuts energy costs, and extends equipment life.

Environmental Sensing Triggered After Irrigation Operation

The smart HVAC system includes a precise humidity sensor and irrigation control. It detects irrigation in real time and adjusts air conditioning modes. When the system sees a quick rise in humidity, it swiftly changes the airflow, temperature, and dehumidification. This helps keep humidity steady and prevents large VPD changes.

Staged Humidity Control Strategies for Smooth VPD Recovery

The smart system uses a phased dehumidification strategy. It adjusts humidity control methods over time after irrigation. At the end of irrigation, it boosts air circulation. This helps increase evaporation with gentle winds, spreading humidity evenly. Then, the system slowly changes the dehumidification strength. This way, the VPD returns to the target range without overdoing it.

Path to Realising Energy-Saving Benefits

Smart HVAC systems improve environmental control and cut energy use. They optimize operation modes and limit unnecessary dehumidification, making them run more efficiently. Plus, these systems adjust based on real-time data, preventing overuse of equipment. This helps extend their lifespan and lowers maintenance costs. This smart control helps plants grow better. Growers save money and manage operations in a sustainable way.

Conclusion

Controlling VPD isn't just about reaching target numbers. It’s also about syncing with the changing rhythm of cannabis. Challenges like daytime spikes and nighttime drops show us that static systems fail. In contrast, dynamic environments grow and succeed, even through wet and cold winters.

Cannabis doesn't require perfect numbers. They need a partner who gets their subtle signals, like stomatal whispers and root sighs. When your HVAC runs smoothly, VPD becomes more than a metric. It turns into your secret cultivation superpower.

FAQ

1、Can I fix VPD issues by just buying a better humidifier?

That’s like putting racing tires on a broken engine. True VPD control needs synced temperature, humidity, and airflow. No single device can solve it.

2、How fast should my system respond to VPD changes?

If your gear takes longer than 3 minutes to react, you’re already losing the battle. Top-tier setups now adjust conditions every 45-90 seconds.

3、Is nighttime VPD really that important if lights are off?

Would you make workers sleep in a flooded basement? Low night VPD drowns roots and invites pathogens. Keep it above 0.4kPa even in darkness.

4、What’s the #1 sign my HVAC isn’t VPD-ready?

If you have mold at the canopy edge or uneven bud growth, your system needs better microclimate control. This is the hidden problem.

5、Can I retrofit old equipment for better VPD?

Yes, but don’t just slap on sensors. Begin with airflow redesign. Smarter ventilation often provides 70% of the gains, not new gadgets.

Share with your friends:

Popular Blogs on Altaqua:

Download Catalogue