Grow Room HVAC Systems Built for Commercial Cultivation

Integrated temperature & humidity control for sealed commercial grow rooms

Stop nighttime humidity spikes and VPD drift

Protect yield, quality, and compliance—without climate-related crop risk

What Is a Grow Room HVAC System — And Why Commercial Growers Use It

Built for 24/7 commercial operation, a grow room HVAC system keeps temperature and humidity tightly controlled across every cultivation stage.

As a result, growers see higher yield consistency, improved product quality, and lower operating costs per cycle.

Integrated Climate Control in One Purpose-Built System

Dehumidification, cooling, heating, and ventilation are combined in one unit.

Energy Efficiency Without Compromising Climate Stability

Hot gas reheat technology improves energy efficiency without sacrificing climate stability.

Smart Control Designed for Commercial Facilities

Advanced WiFi remote control and seamless Modbus integration.

How the System Manages Temperature and Humidity Together

During dehumidification, moisture removal comes first—while temperature is automatically adjusted to keep the room on target.

Proven in Commercial Grow Rooms Worldwide

Used in sealed flower rooms and high-density commercial facilities, these projects demonstrate stable climate control under real-world grow loads.

Model: GAS-45D *6 Pcs

Total Cooling Capacity: 45 ton*6 Pcs

Water Removal: 99.8L/hr*6 Pcs

Cannabis Flower Room Project in the USA

Model: GAS-15D*13 Pcs

Total Cooling Capacity: 14.63 ton*13 Pcs

Water Removal: 32.3L/hr*13 Pcs

Cannabis Flower Room Project in the USA

Model: GAS-65D*2 Pcs

Total Cooling Capacity: 66.5 ton*2 Pcs

Water Removal: 147L/hr*2 Pcs

Cannabis Flower Room Project in Thailand

Model: GAS-20D*2 Pcs

Total Cooling Capacity: 21.1 ton*2 Pcs

Water Removal: 47L/hr*2 Pcs

Cannabis Grow Room Project in New Zealand

One HVAC Design — Tuned for Every Grow Room

Altaqua grow room HVAC systems are not just about cooling or dehumidifying. Each unit is designed to handle changing loads, built-in redundancy, and scalable operation—so performance stays consistent as conditions change.

Each grow room has different climate requirements—so the HVAC design adapts to each phase.

Mother Room

Stable temperature and gentle airflow.

Clone Room

Controlled humidity for rooting success.

Vegetative Room

Balanced cooling and humidity control.

Flower Room

Precise dew point control and airflow.

Drying Room

Low humidity and stable curing conditions.

By tailoring climate design to each stage, growers can achieve higher yield, consistency, and product quality.

Every facility is different—and so is the right HVAC design.

Not Sure Which Grow Room HVAC System Fits Your Facility?

Contact us and let grow room HVAC experts tailor the right system for you.

We’ll recommend the most suitable grow room hvac equipment based on your actual conditions—helping you cut energy costs, stabilize climate, and boost cannabis quality.

Talk to HVAC Engineers

10 Design Reasons Commercial Growers Achieve a Stable Climate with Altaqua

Altaqua grow room HVAC systems are not standalone machines — they’re part of a complete grow room climate design.

This integrated approach helps ensure the entire room reaches and holds set conditions, protecting yield and investment.

Your setpoints stay steady—no chasing swings, less crop stress.

Keeps temperature within ±0.5°C and dew point within ±1°C using real-time control logic to prevent overshoot.

You control real moisture content—not misleading RH percentages.

Dew point is unaffected by temperature swings, making it ideal for stable VPD and consistent dehumidification targets.

Better data means fewer surprises and more consistent results.

Industrial HVAC sensors (Austria) with accuracy up to ±2.5% RH and ±0.3°C across a wide operating range.

No single failure should take your room offline.

Multiple control circuits keep operation stable—even if one module goes offline—reducing downtime risk.

See system status fast and stay in control.

Touchscreen lets you set targets, monitor real-time VPD, view alarms, and run diagnostics quickly.

Less manual tweaking—more consistency across rooms.

24/7 remote monitoring via WiFi with Modbus integration for centralized facility management and automated adjustments.

Stable airflow with lower power draw.

High-efficiency EC motors deliver precise speed control, quieter operation, and reduced energy consumption.

Proven components reduce long-term reliability risk.

Built with suppliers like Copeland, Danfoss, ABB, Siemens, Schneider, and OLAB for dependable performance.

Stable supply air temperature during dehumidification—without extra heating cost.

Captures heat from the cooling cycle and reuses it to reduce energy waste while minimizing room fluctuations.

Uniform conditions across the canopy—fewer hot/cold pockets.

Designed for ducted airflow to improve canopy uniformity and help reduce mold, pests, and disease pressure.

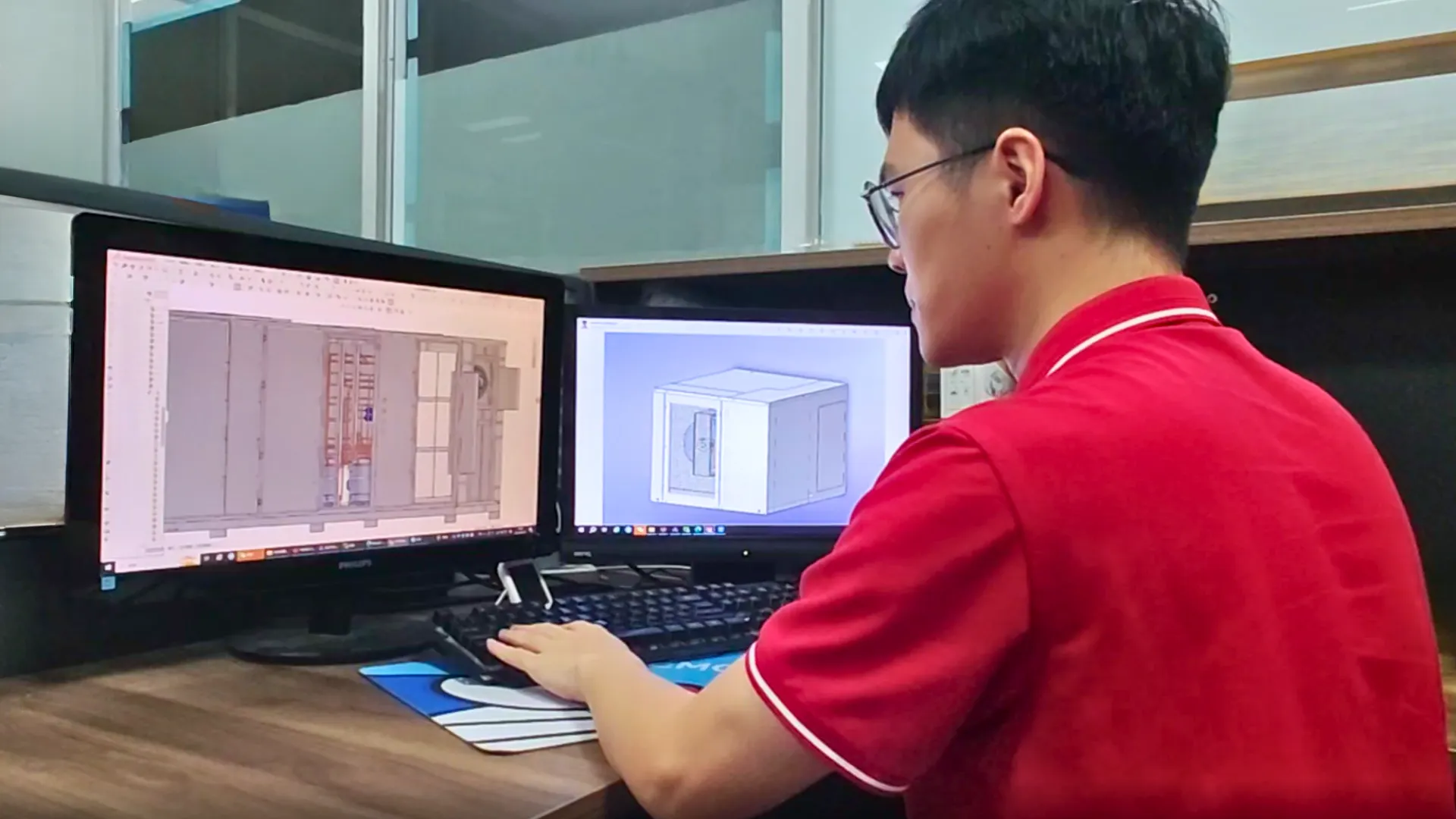

More Than a Manufacturer — Your Grow Room HVAC Design Partner

Altaqua is not just an HVAC factory, we act as your design consultant. Drawing on decades of engineering experience as well as real-world growing grounds, our team delivers custom-built answers for every grow room.

Purpose-built grow room hvac equipment with dependable control, demonstrated manufacturing, and complete service.

Reliable Control Algorithms Design

Integrated intelligent algorithms use temp & humidity to auto adjust modes for the most accurate climate and dew point control.

Experienced Manufacturing Team

More than 17 years of skilled experience with precision in each production process.

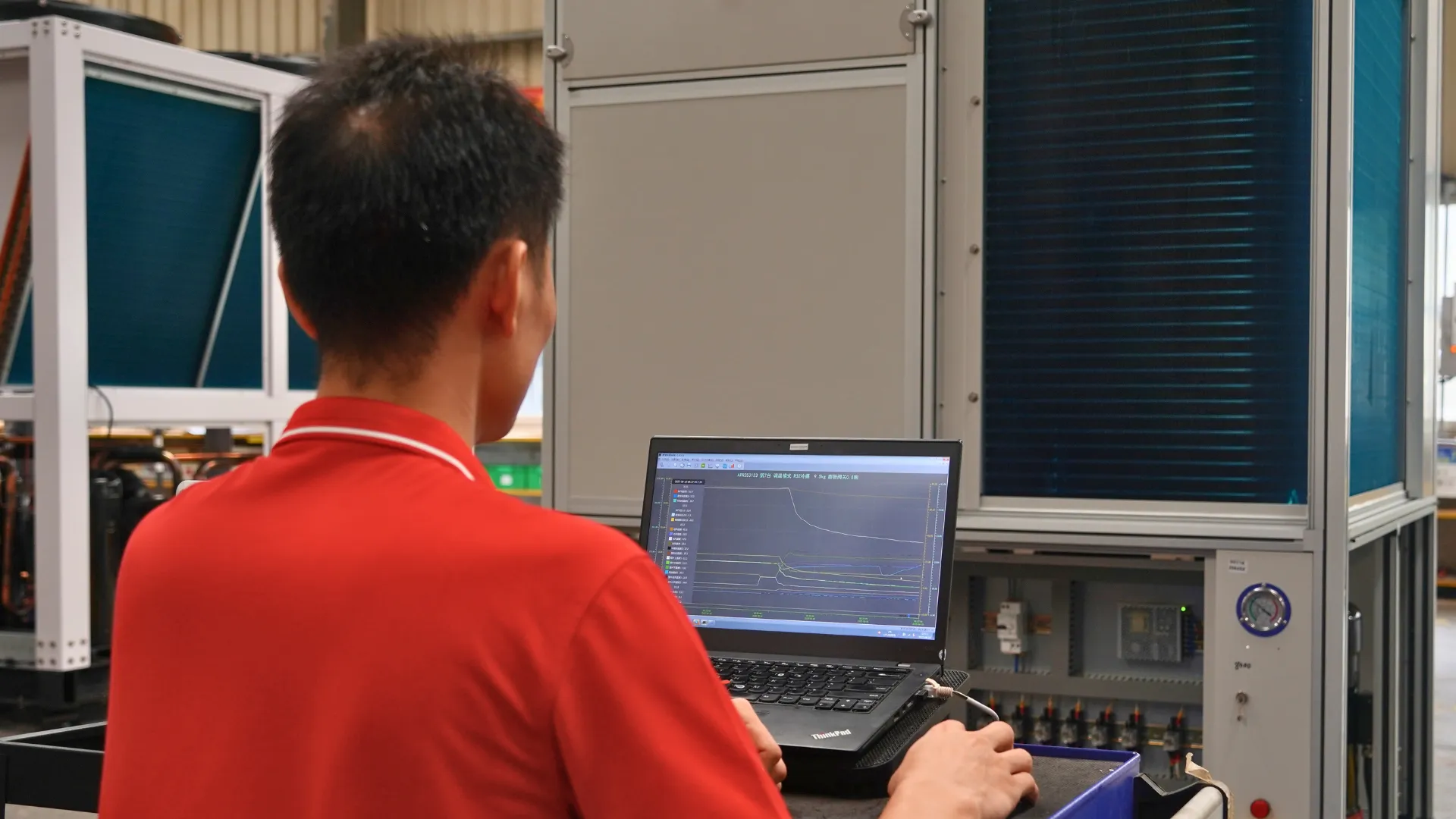

Strict Quality Control & Testing

All units are full pressure tested, performance verified and saving traceability documentation.

Secure Packaging for Transport

Durable multi-layer packaging ensures each unit stays safe and undamaged during long-haul transportation.

Full Installation Support

With straight forward manuals, tutorial videos and technical support, make installation quick, simple, and hassle-free.

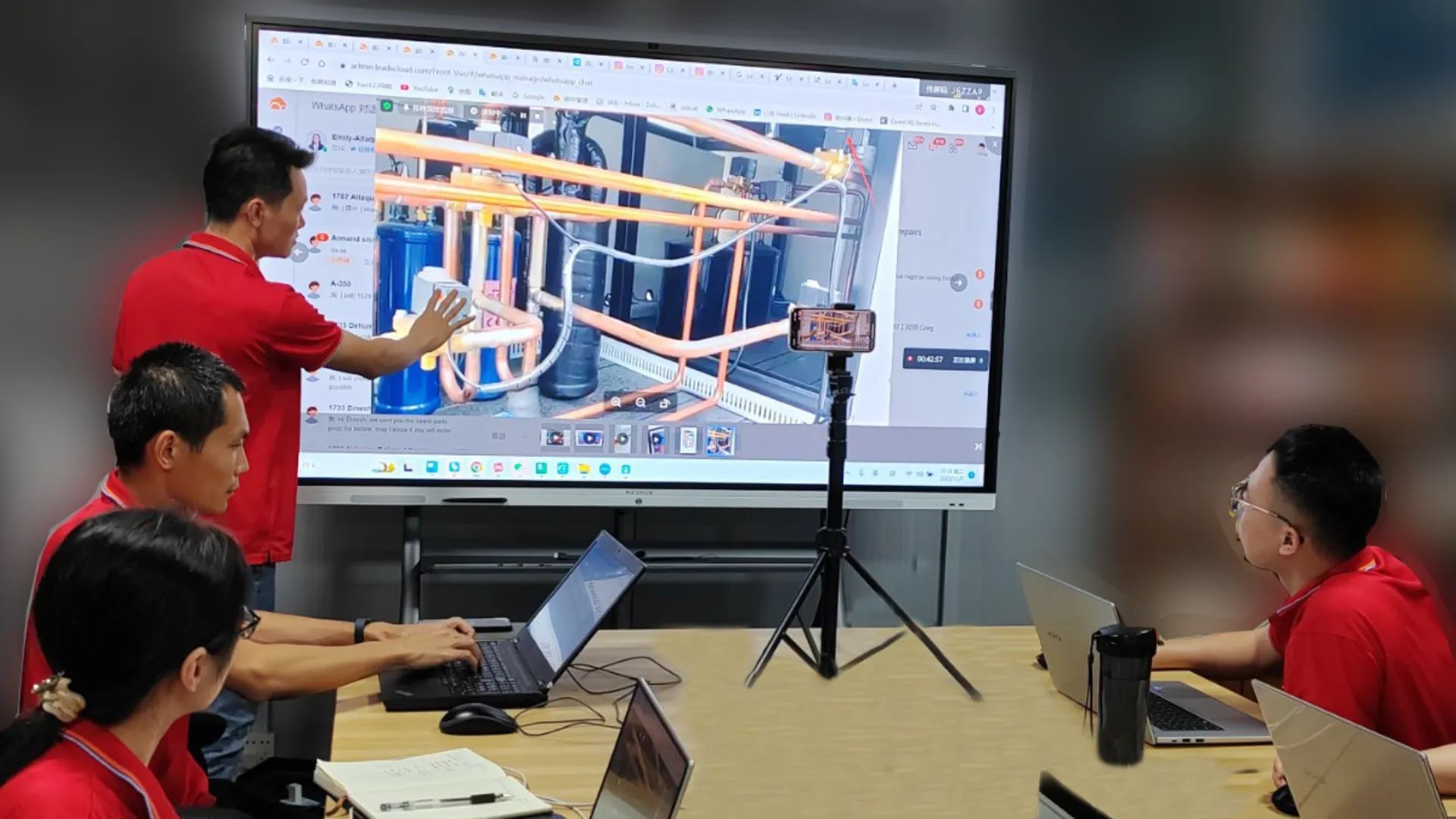

HVAC Expert Team Online Guidance

Grow room HVAC experts provide real-time online guidance, help make system integration a snap and protect your investment with professional after-sales service.

17+ Years of HVAC Experience Behind Every Grow Room System

Altaqua has over 17 years of experience in HVAC and refrigeration manufacturing. In 2019, leveraging our expertise in the indoor swimming pool industry, we expanded into grow room hvac design, an industry that demands the same stringent requirements for high latent moisture control and durability.

We maintain close relationships with commercial growers, building long-term partnerships to understand their specific needs. This direct feedback enables us to refine system performance and customize solutions that are more suitable for cannabis cultivation.

Certified by International ISO Standards

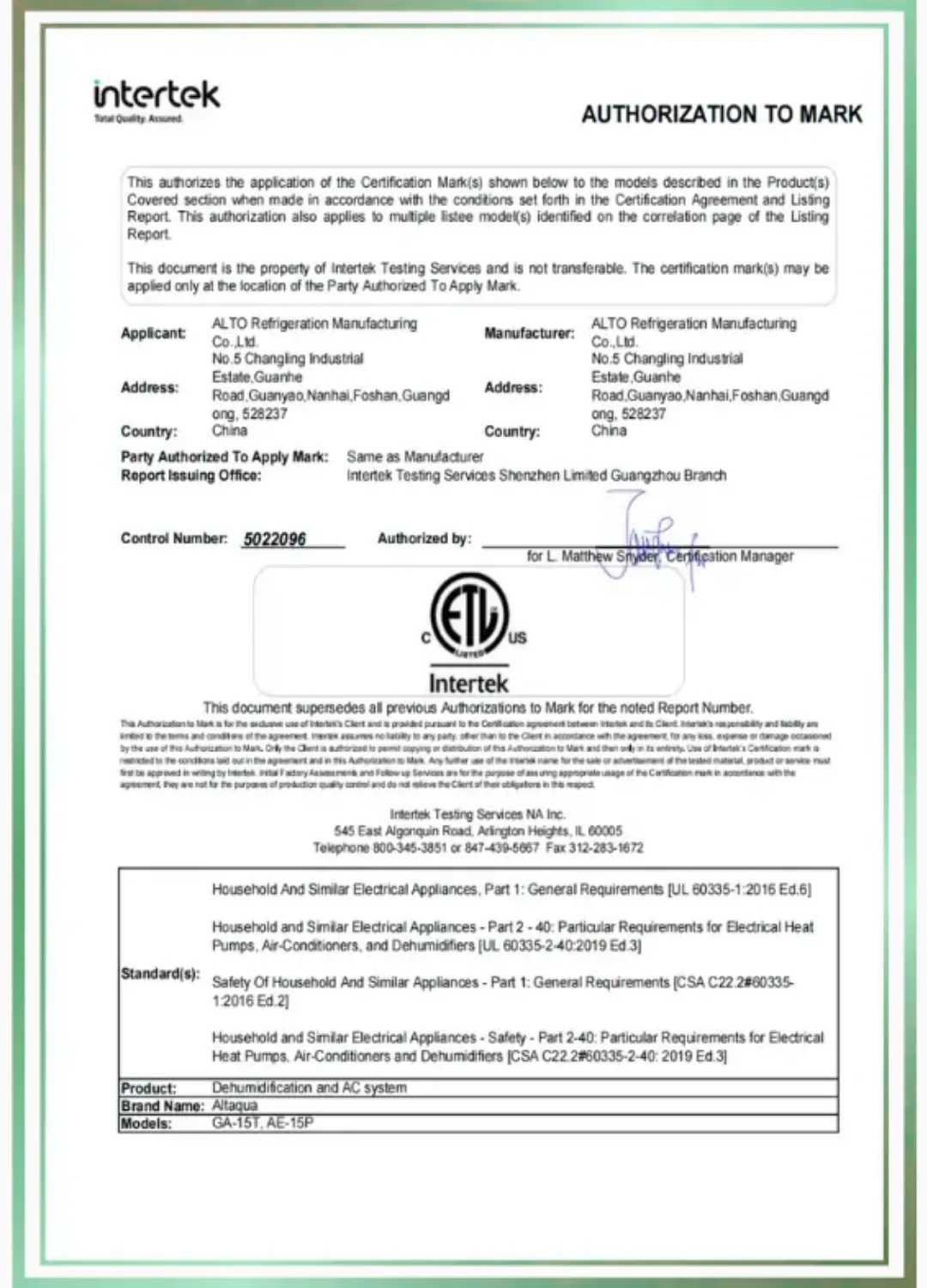

Certified for Global Safety and Compliance

ETL Certificate

Altaqua Grow Room HVAC Systems have been certified by Intertek's ETL program. The ETL mark indicates that our products comply with North American safety standards. It is recognized by authorities and regulatory agencies in the United States and Canada.

This certification verifies compliance in areas such as electrical safety and mechanical safety. It reflects Altaqua’s high standards in design and manufacturing and our commitment to user safety.

Strong Innovation Capability with 69 Patent Granted

Get A Free Proposal