Powdery Mildew on Cannabis: Why Grow Room HVAC Design Matters More Than Treatment

Updated: Jan. 12 ,2026 · 4 min read

Abstract: Powdery mildew is one of the most common problems in commercial cannabis facilities, but it is rarely caused by plant health alone. In most cases, unstable humidity, poor airflow, and HVAC systems designed for comfort cooling create the conditions that allow mildew to thrive. This article explains why standard HVAC systems struggle in grow rooms, how microclimates increase fungal risk, and how properly engineered grow room HVAC design—with precise humidity control, dew point management, and balanced air distribution—helps prevent recurring mildew issues through long-term environmental stability.

Powdery mildew is one of the most common and costly problems in commercial cannabis facilities. When it appears, the first reaction is often to look for a treatment solution — sprays, surface cleaning, or emergency interventions.

But in reality, powdery mildew is rarely a plant-level problem. It is almost always an environmental control problem.

Unstable humidity, poor air distribution, and HVAC systems designed for comfort cooling — not cultivation — create the exact conditions powdery mildew needs to thrive. Without addressing these system-level issues, outbreaks tend to return, no matter how aggressively they are treated.

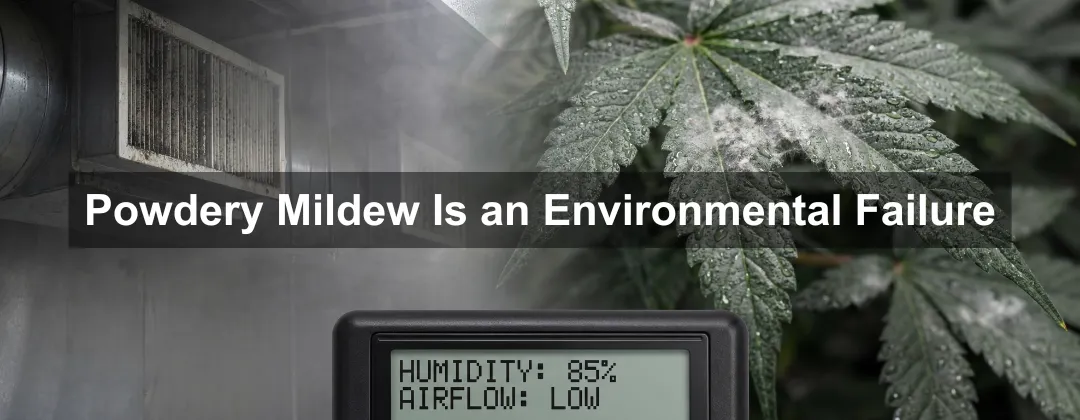

Powdery Mildew Is an Environmental Failure, Not a Plant Issue

Powdery mildew develops when moisture lingers on plant surfaces in warm, stagnant air. These conditions are not random — they are the result of environmental instability inside the grow room.

Common contributing factors include:

- Elevated relative humidity (RH)

- Nighttime humidity spikes

- Poor air circulation across the canopy

- Localized condensation on leaf surfaces

In many facilities, temperature appears to be under control, but humidity is not. Traditional HVAC systems are often designed to regulate air temperature, not to manage moisture removal under high latent load conditions. As a result, humidity drifts into the danger zone, especially during lights-off periods.

From an engineering perspective, powdery mildew is a symptom of inadequate humidity and airflow control.

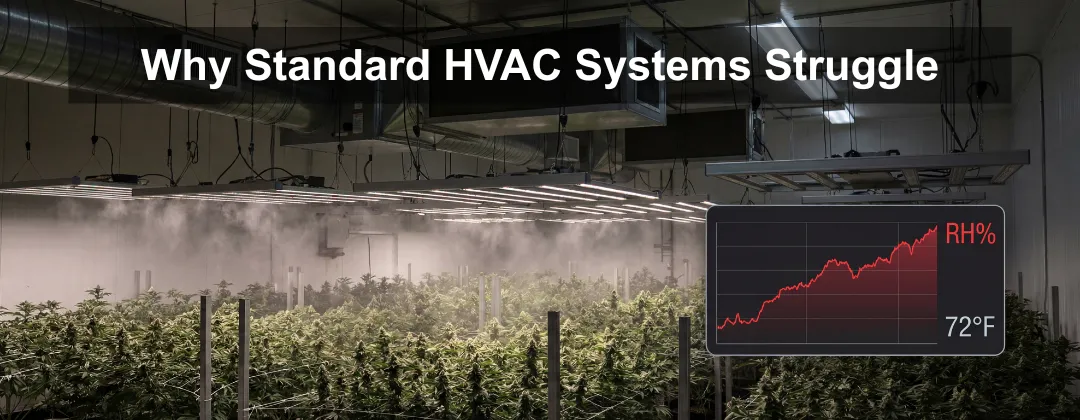

Why Standard HVAC Systems Struggle in Grow Rooms

Most HVAC systems out there are built for people, not for plants. Offices, homes, shopping malls — that’s what they’re designed for.

Grow rooms? Totally different story.

In a cultivation space, you’re dealing with things like:

- Plants constantly releasing moisture into the air

- Humidity swinging up and down throughout the day

- Thick canopies that trap moisture underneath

And the need to keep the environment stable, not just “comfortable”

Traditional comfort cooling focuses mainly on temperature — removing sensible heat. But in grow rooms, moisture (latent heat) is often the real challenge. If the system isn’t designed to actively manage humidity and control dew point, things start to get messy.

What usually happens?

- The thermostat says the temperature is fine, but RH is all over the place

- Moisture builds up around the canopy

- And suddenly, fungal issues become a real risk

So yeah — just “running the AC” doesn’t mean your grow room is actually under control. Stable cultivation environments need more than basic cooling.

Humidity, Airflow, and Microclimates

Grow rooms aren’t as “even” as they look. On paper, the average temperature and humidity might seem fine, but inside the canopy, it can be a totally different world. Small pockets of weird conditions — microclimates — show up all the time, especially in spots where airflow is weak.

In those areas, you usually see things like:

- More moisture hanging around leaf surfaces

- Less air movement inside dense plant zones

- Little temperature differences from one spot to another

The problem is, most sensors are stuck on the wall or in the return duct. They tell you what the room generally feels like — not what the plants are actually experiencing. So while the data looks “normal,” powdery mildew can quietly get comfortable and spread before anyone notices.

That’s why a good HVAC setup for grow rooms has to do more than just hit a setpoint. It needs to:

- Move air evenly through the space

- Keep moisture under control right at canopy level

- Make sure fresh air is always circulating across every plant surface

Because in the end, what matters isn’t what the sensor says — it’s what the plants feel.

How Proper Grow Room HVAC Design Reduces Mildew Risk

Preventing powdery mildew begins with controlling the environmental conditions that allow it to grow.

A properly designed grow room HVAC system focuses on:

1. Precision Humidity Control

Dedicated dehumidification capacity ensures moisture is removed consistently, even during high-transpiration periods and nighttime cycles.

2. Dew Point Management

Keeping the dew point under control helps stop condensation from forming on the leaves. And once you remove that surface moisture, fungi lose one of their favorite growing conditions.

3. Balanced Air Distribution

Good airflow design isn’t just about moving air — it’s about moving it everywhere. When air reaches the whole canopy, those dead, stagnant corners disappear, and the room stays more consistent overall.

4. Stable VPD (Vapor Pressure Deficit)

A steady VPD keeps moisture moving the way it should — out of the plant, not sitting on the surface. No excess moisture hanging around, no extra problems.

5. 24/7 Environmental Stability

Grow rooms don’t get breaks. Lights change, plants grow, seasons shift — and the HVAC system has to keep up with all of it, day and night, without falling behind.

When all of these pieces work together, the room itself becomes a pretty unfriendly place for powdery mildew — no chemicals needed, just solid environmental control.

Preventing Recurring Mildew Starts With Environmental Control

Treating mildew addresses the symptom, not the cause. Environmental instability is what allows mildew to return.

Facilities that rely solely on reactive solutions often face repeated outbreaks of powdery mildew, along with rising labor and material costs, increased risks to crop quality, and growing compliance challenges. In contrast, facilities that invest in proper HVAC system design benefit from reduced fungal pressure, fewer intervention requirements, more predictable crop performance, and improved overall operational stability. Environmental control is not a short-term fix — it is a long-term risk management strategy.

Why Commercial Facilities Choose Integrated Grow Room HVAC Systems

Integrated grow room HVAC systems combine temperature control, dehumidification, and airflow management into a single, coordinated platform.

Compared to fragmented setups using separate air conditioners and portable dehumidifiers, integrated systems offer:

- Centralized environmental control

- More accurate humidity regulation

- Higher energy efficiency

- Simplified operation and maintenance

- Greater reliability under heavy cultivation loads

By addressing both sensible and latent loads simultaneously, integrated HVAC systems create stable growing environments that naturally suppress fungal development.

Conclusion: Fix the Environment, Not Just the Symptoms

Powdery mildew is not just a plant problem — it is an environmental control problem. If mildew keeps appearing, the issue is rarely the crop itself. It is the humidity, airflow, and system design behind the scenes.

A properly engineered grow room HVAC system provides consistent humidity control, stable dew point management, uniform air distribution, and long-term environmental reliability. When the environment is controlled correctly, the conditions that allow powdery mildew to thrive simply disappear.

Environmental stability isn’t just about comfort — it’s about protecting your yield.

FAQ

1、Is powdery mildew on cannabis caused by poor plant health?

Powdery mildew is rarely caused by plant health alone. In most commercial grow rooms, it develops because of environmental instability — especially high humidity, poor airflow, and inadequate moisture control. When HVAC systems focus only on temperature and fail to manage humidity and dew point, conditions become ideal for fungal growth.

2、Why doesn’t standard air conditioning prevent powdery mildew in grow rooms?

Most regular AC systems are built to keep people comfortable, not to deal with the heavy moisture load inside a grow room. They’re good at controlling temperature, sure — but when it comes to pulling out enough humidity or managing dew point, they usually fall short.

So what happens?

At night especially, moisture builds up, humidity drifts, and the environment slowly turns into a perfect place for powdery mildew to grow.

3、How does proper grow room HVAC design reduce mildew risk?

A well-designed grow room HVAC system does more than just cool the space. It keeps humidity in check, manages dew point properly, and pushes air evenly through the canopy.

When the environment stays stable around the clock — lights on, lights off, season to season — mildew simply doesn’t get the conditions it needs to spread. That means fewer emergency treatments, less stress, and better long-term protection for your crops.

Share with your friends:

Popular Blogs on Altaqua:

Download Catalogue