Customized HVAC

for Cannabis Cultivation

Accurate Humidity and Temperature Control

Built for Commercial Cannabis Cultivation

Prevent Pests and Mold for High Yield

Customized HVAC

for Cannabis Cultivation

Accurate Humidity and Temperature Control

Built for Commercial Cannabis Cultivation

Prevent Pests and Mold for High Yield

Customized HVAC

for Cannabis Cultivation

Accurate Humidity and Temperature Control

Built for Commercial Cannabis Cultivation

Prevent Pests and Mold for High Yield

Customized HVAC

for Cannabis Cultivation

Accurate Humidity and Temperature Control

Built for Commercial Cannabis Cultivation

Prevent Pests and Mold for High Yield

Customized HVAC

for Cannabis Cultivation

Accurate Humidity and Temperature Control

Built for Commercial Cannabis Cultivation

Prevent Pests and Mold for High Yield

Grow Room HVAC Applications

Integrated

HVAC Functions

Both temperature and humidity are high, it cools and dehumidifies simultaneously.

Humidity is high but temperature is lower than setpoint, it heats while dehumidifying.

Temperature is near the setpoint, it fine-tunes temperature during dehumidification.

When no temperature or humidity adjustment is needed, compressor remains off and the fan circulates air.

Monitor and regulate CO₂ levels to aid photosynthesis.

Built-in UV sterilization and MERV 8 filters effectively eliminate pathogens.

Continuous fresh air exchange maintains optimal CO2 levels and humidity balance.

Remotely monitor and manage the system 24/7 via mobile devices, with trend tracking and fault alerts.

Key Advantages

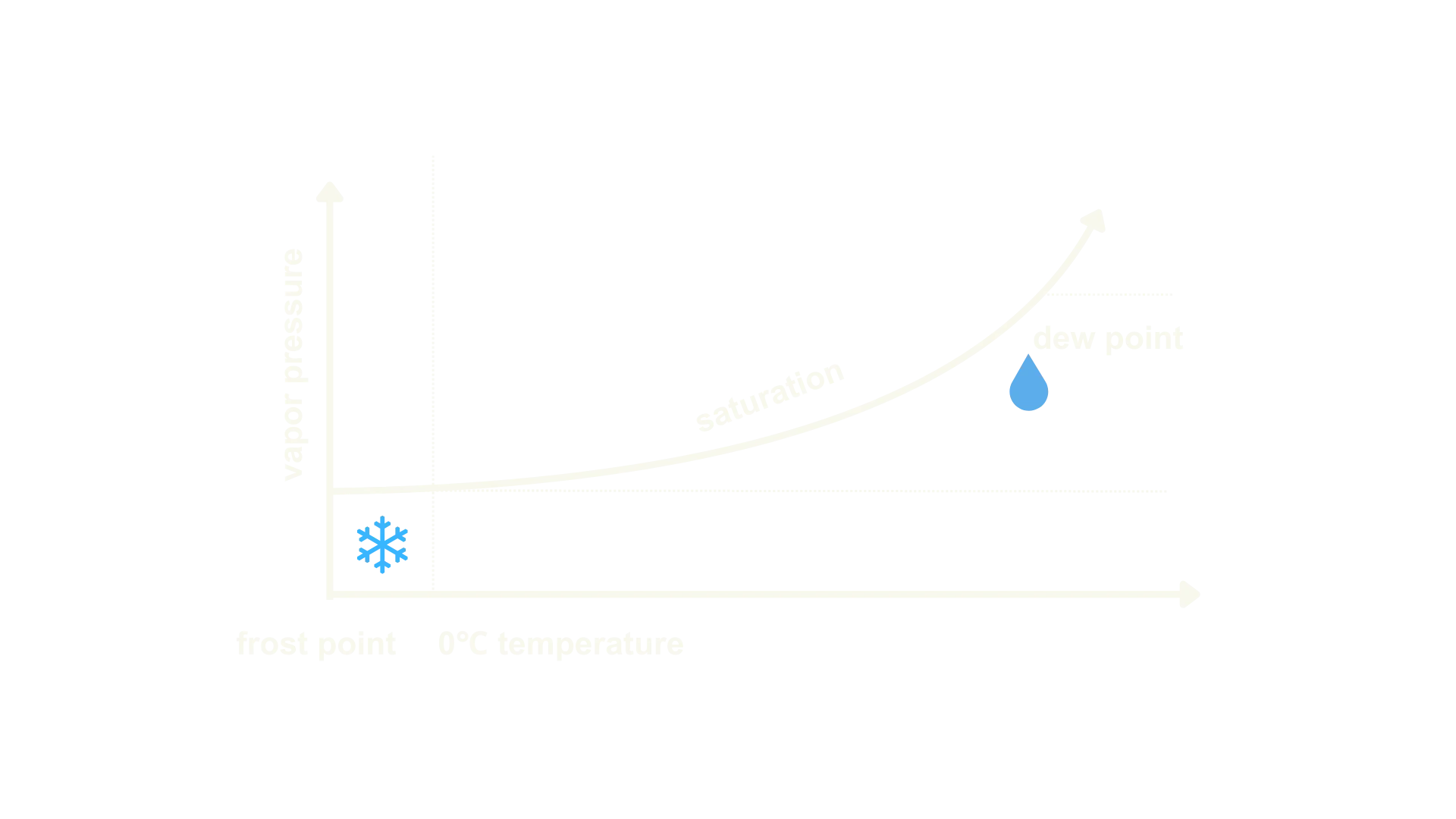

- Dehumidification prioritizes water contents in the air removal over relative humidity reduction reduction.

- Dew point measurement reflects true vapor content unaffected by temperature fluctuations.

- Dew point control demonstrates scientifically validated superiority to RH control methods.

- EE160 RH and Temp sensor is designed for HVAC.

- Accurate humidity control from -40°C to +60°C range.

- Offers ±2.5% RH and ±0.3°C for high accuracy.

- User adjusts ideal RH and temp as needed.

- Redundant design uses multiple control circuits to keep the operation running smoothly nonstop.

- If one module goes down, the others keep working, ensuring there’s no interruption or system downtime.

- Works efficiently by adjusting system operation based on real-time grow room load conditions.

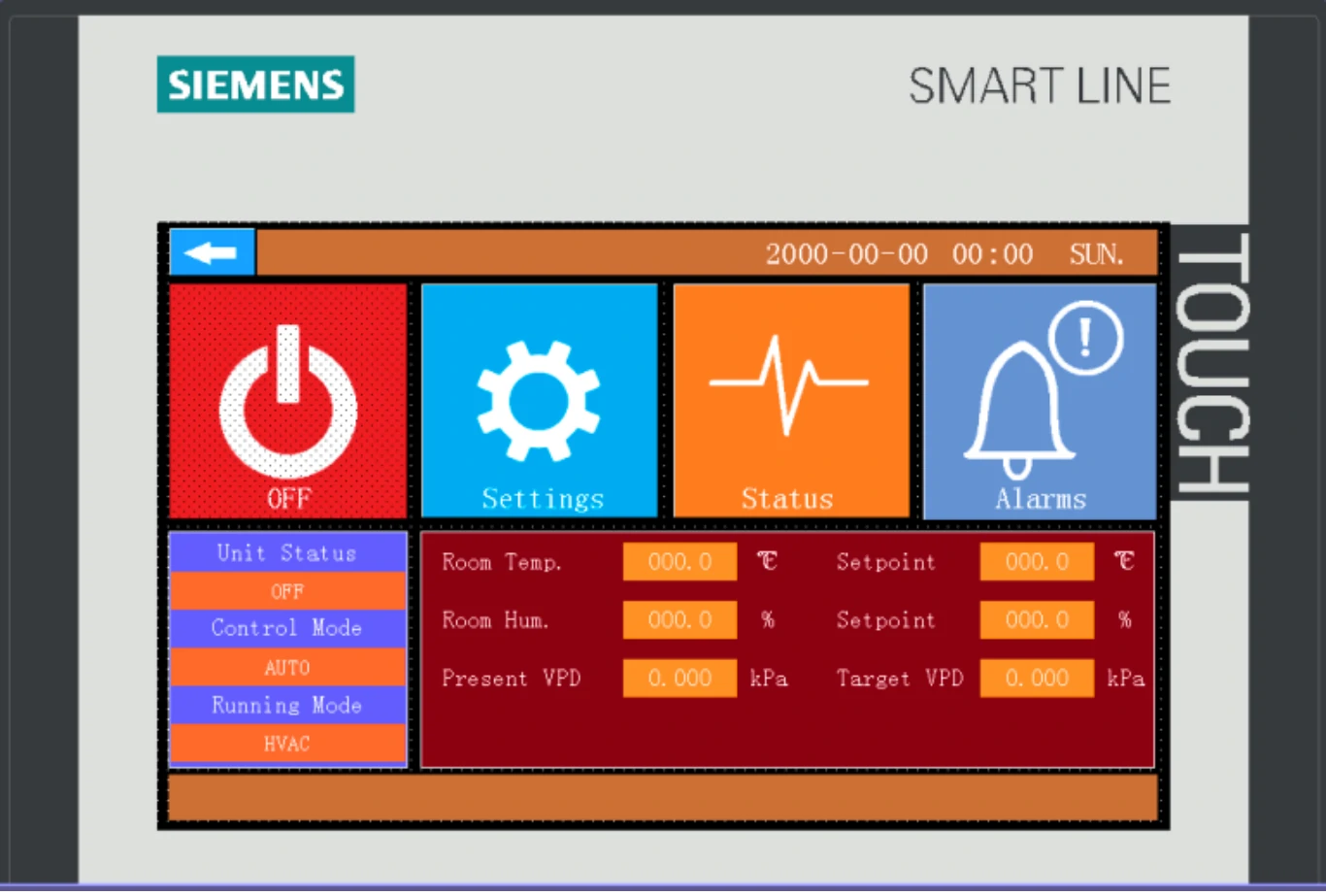

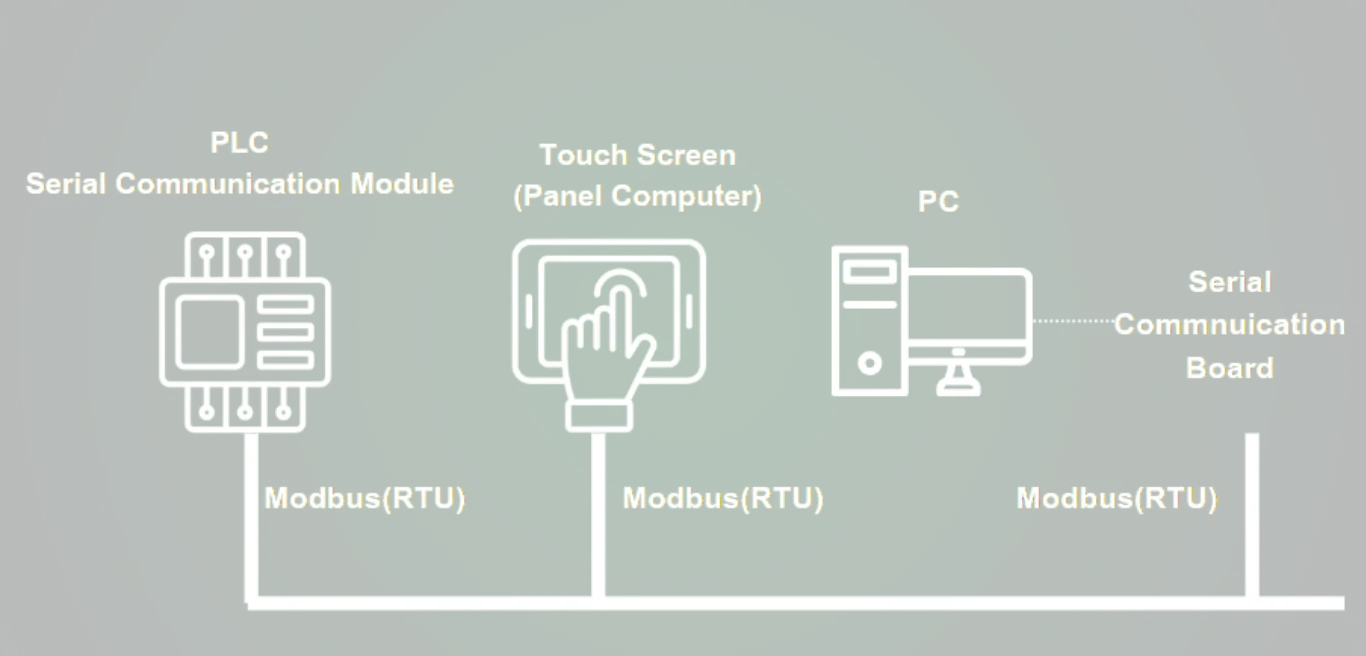

- Intuitive interface with touchscreen navigation.

- Set target temp/humidity and monitor real-time VPD.

- View alerts, diagnostics, and stats all in the screen.

- External rotor motor allows for compact design.

- Full speed control with analog or serial input.

- GreenTech EC tech ensures high efficiency.

- Quiet run with smart EC motor commutation.

- Panasonic, Danfoss, and Copeland compressors.

- Schneider AC contactors control power flow.

- ABB Variable Frequency Drives adjust motor speeds.

- Siemens PLC controller automates system logic.

- Emerson oil separator removes oil from refrigerant.

- OMRON solenoid valves control refrigerant flow.

- REFCO pressure gauges measure system pressure.

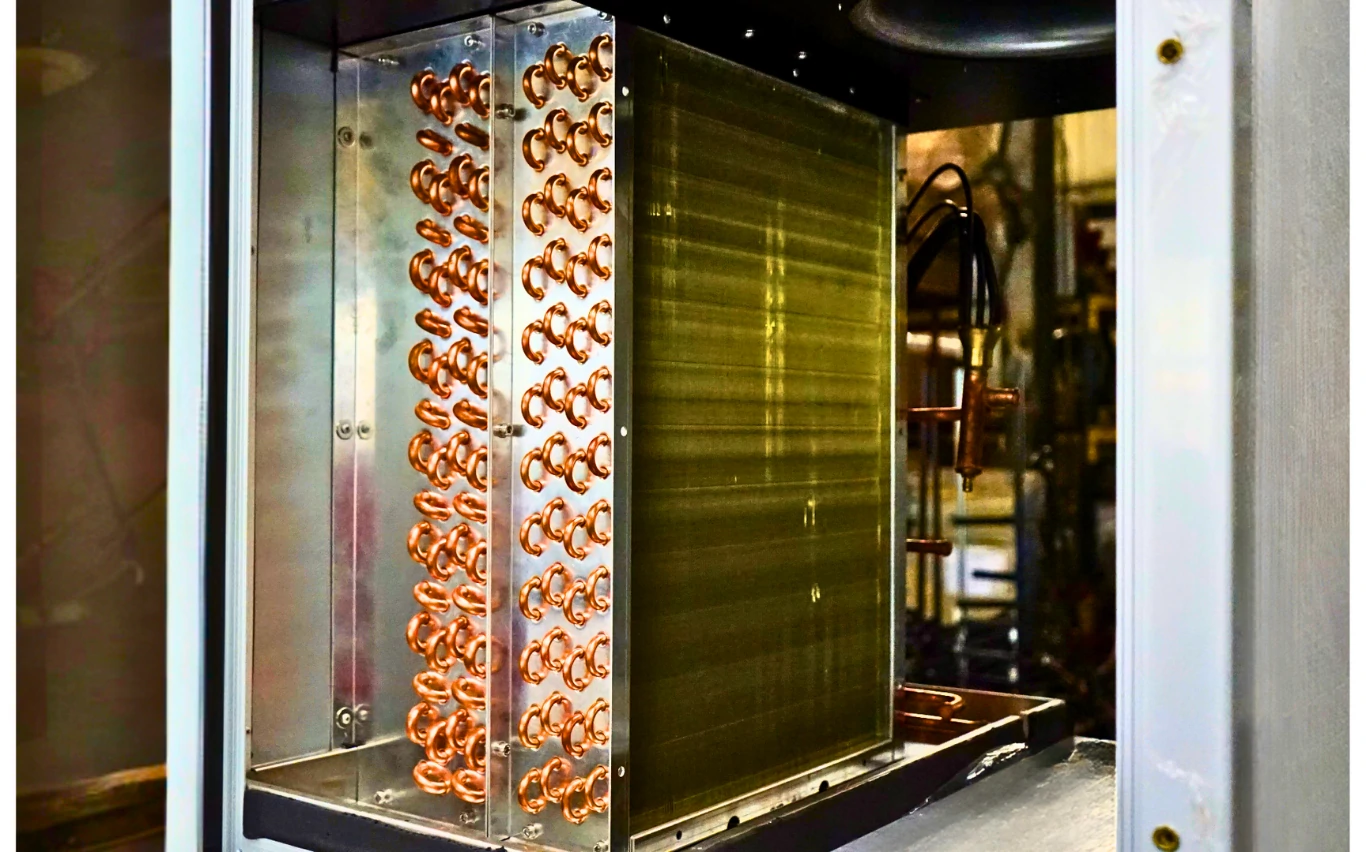

- Reheat coil features copper pipes with inner threads and aluminum fins for efficient heat transfer.

- It captures and reuses waste heat generated during cooling cycle to maximize energy usage.

- Reheats the dry, cool air before it flows back into the grow room to maintain proper conditions.

- Reduces heating energy use while minimizing temperature and humidity fluctuations in the room.

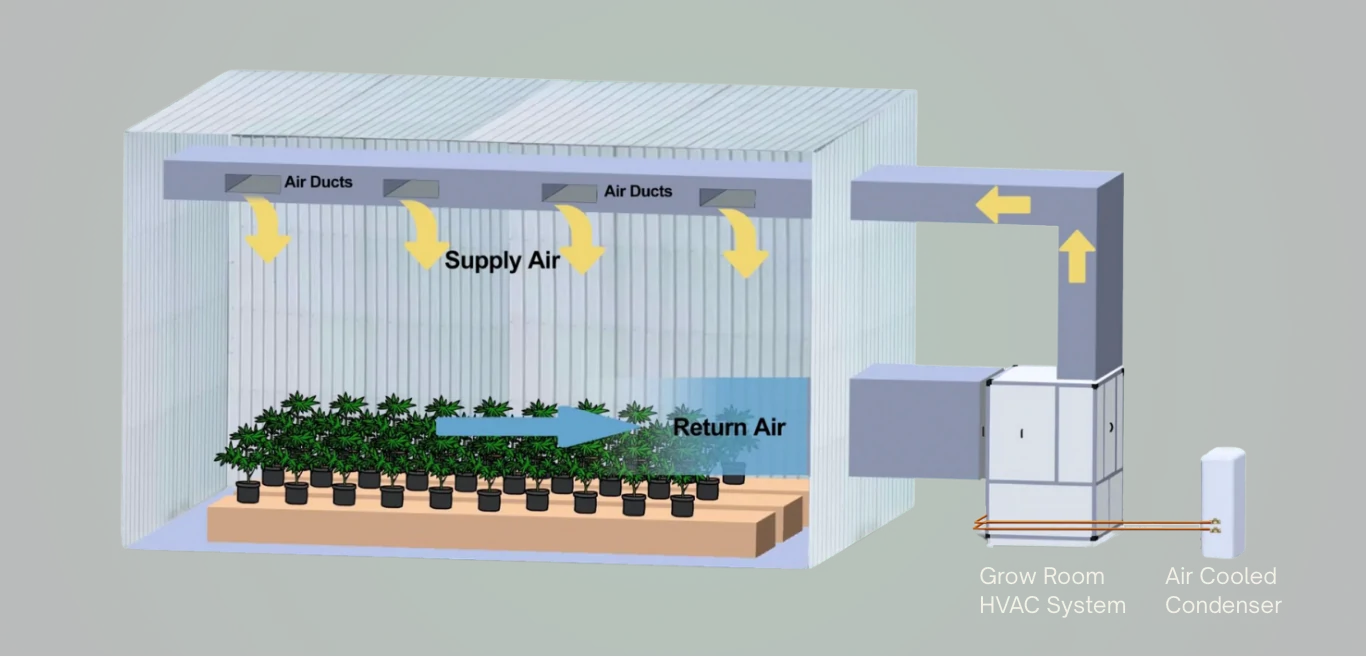

- Our system works efficiently with air duct designs.

- Air ducts prevent hot or cold spots in grow rooms.

- Steady airflow keeps temp and humidity stable.

- Plants grow evenly across the entire canopy.

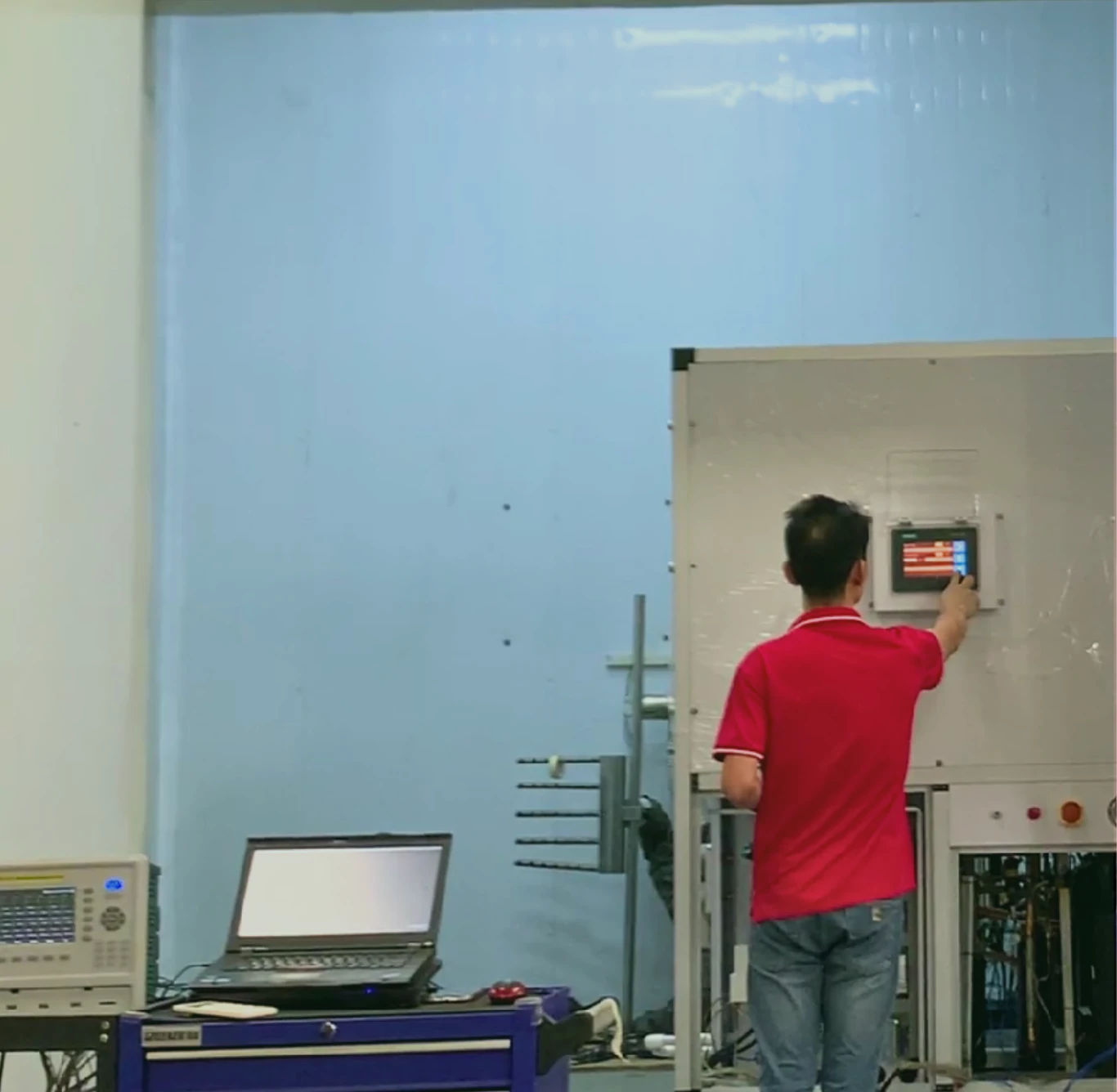

Easy Installation and Operation

Quick setup with connecting ductworks, wiring, and basic humidity and temperature configuration.

Standard HVAC techs can install it with our clear guides and support.

Set ideal temperature and humidity, then activate auto mode. The system will adjust in real time to maintain optimal conditions.

Monitor data and adjust settings anytime via phone or PC. Get instant fault alerts to avoid downtime and crop loss.

Easily connects to building systems for centralized control. Enables real-time tracking and data-driven performance tuning.

Why Choose Altaqua HVAC

Reliable Control Algorithms Design

Built-in smart algorithms analyze temp & humidity to auto-adjust modes for precise climate and dew point control.

International Brand Components

Uses reliable components from ABB, Panasonic, and Danfoss to ensure long-term trusted performance.

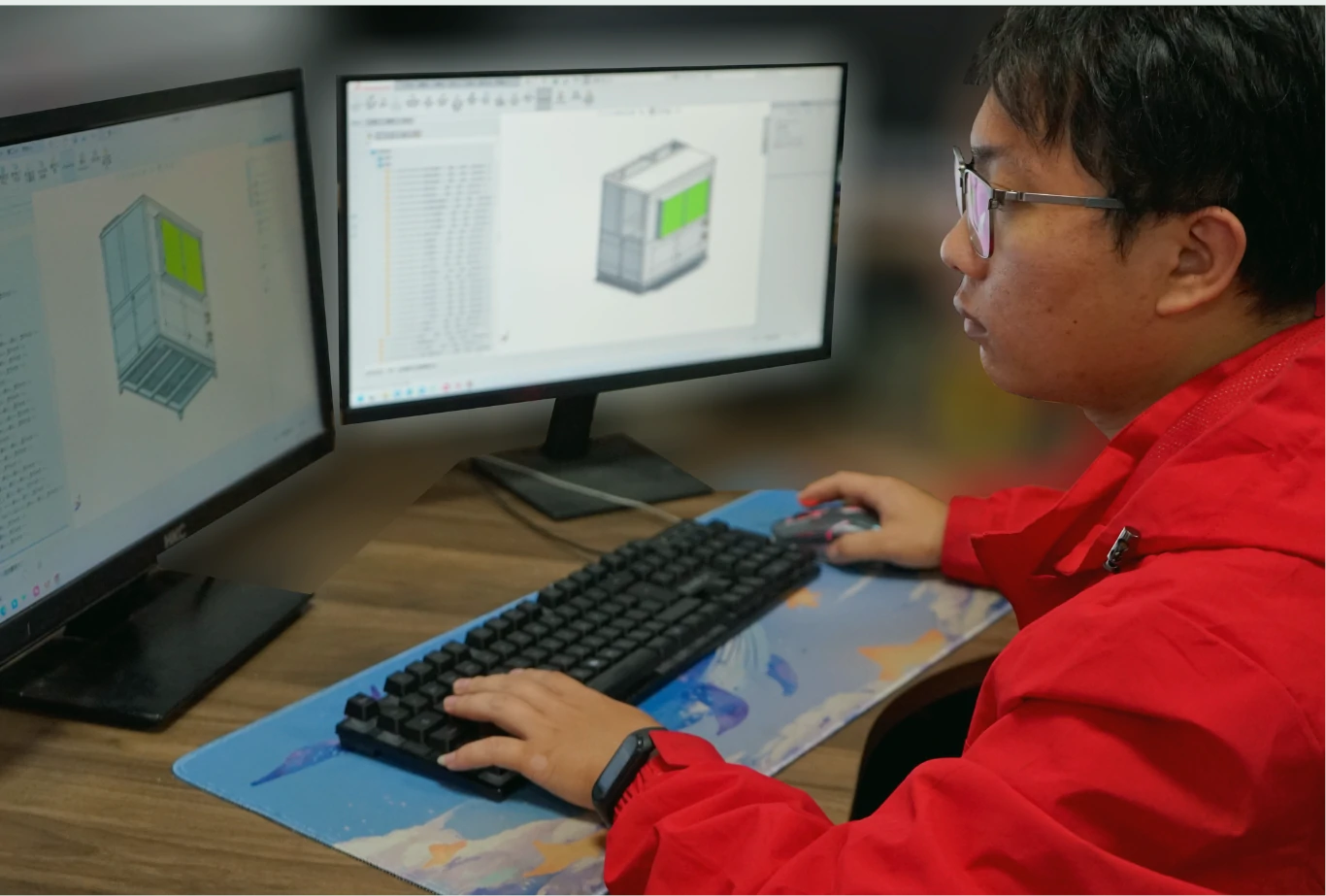

Experienced Manufacturing Team

Over 16 years of expertise with ISO 9001-certified precision in every step of the production process.

Strict Quality Control & Testing

Every unit undergoes full pressure testing, performance verification, saving traceability documentation.

Secure Packaging for Transport

Durable multi-layer packaging ensures each unit stays safe and undamaged during long-haul transportation.

Full Installation Support

Easy-to-follow manuals, tutorial videos, and expert support make installation quick, simple, and hassle-free.

Responsive After-Sales Service

Responsive technical support keeps your system running smoothly and helps safeguard your crops at all times.

Know about Altaqua HVAC Products

Get Altaqua HVAC Catalog

Looking to upgrade your grow room with an integrated HVAC

system? Don't hesitate! Our product manual's got it all — clear

specs, standout features, and super simple installation guides.

Featured

Success Projects

Our HVAC systems have been successfully implemented in various commercial grow rooms, helping cultivators maintain optimal environmental conditions for improved plant health and consistent yields.

Professional Service & Support

Pre-Sales Services

Sales Services

After-Sales Services

Talk to HVAC Engineers

Contact With HVAC Experts

Altaqua Focus on HVAC from 2008