VPD for Veg: How Professional Grow Room HVAC Ensures Stable Growth

Updated: Dec. 17 ,2025 · 5 min read

Abstract: VPD for veg is the stage where most grow rooms lose climate stability. High humidity, rapid load swings, and uneven airflow make traditional AC + dehumidifier setups fail fast—costing growers growth, consistency, and profit. A professional grow room HVACD system changes the equation by keeping temperature and humidity under precise, independent control, delivering the stable VPD for veg that commercial cultivation truly depends on.

Once you step into commercial cultivation, VPD stops being just a number scribbled on a whiteboard. It becomes a climate-control metric that directly affects your ROI, yield stability, and even the quality of your buds.

And during the vegetative stage, this becomes painfully obvious—high humidity, active stomata, and rapid growth demand a level of environmental control that traditional AC-plus-dehumidifier setups simply can’t deliver.

In a commercial grow room, understanding VPD isn’t enough.

The real advantage comes from being able to stabilize VPD.

That’s why more and more growers are rethinking the HVAC systems they rely on.

VPD for Veg Isn’t a Growing Trick—It’s a Stress Test for Your HVAC System

A lot of growers understand VPD only as a formula or a preferred range.

But walk into any commercial grow room and you'll immediately realize VPD is incredibly dynamic:

- Lights turn on → temp rises, RH drops

- AC kicks in → temp falls, RH drops even further

- Irrigation → humidity spikes

- VPD varies by 0.2–0.3 kPa within the same room

None of these swings are about growing skills.

None of these swings are “grower mistakes.”

They’re all reflections of HVAC performance.

Commercial growers don’t need a “perfect VPD chart.”

They need:

- A grow room HVAC system that keeps VPD for veg within a stable, predictable range.

Veg Requires High Humidity—but the Higher the Humidity, the Harder It Is for HVAC to Stay in Control

Veg likes it humid — there’s no way around that. Most growers aim for a VPD around 0.7–1.0 kPa, which usually puts relative humidity somewhere in the 65–75% range.

And honestly, plants love it there. Transpiration flows better, root pressure builds, and vegetative growth really starts to pick up.

But that same humidity is where things get tricky. Once RH climbs, growers start dealing with a few familiar headaches: higher disease pressure like powdery mildew or botrytis, airflow dead zones that suddenly matter a lot more, and leaves that are one step away from surface condensation.

For HVAC systems, this is the danger zone. High humidity is the hardest condition to hold steady—and it’s also the most critical if you’re trying to keep VPD for veg on target. Even a small cooling adjustment can knock RH down by 10–15%, pushing VPD way out of range before you even realize what happened.

So keeping veg rooms “humid but safe” isn’t just about dialing in a grow strategy. It takes a commercial grow room HVAC system that’s actually designed for precision, not one that’s fighting the environment every step of the way.

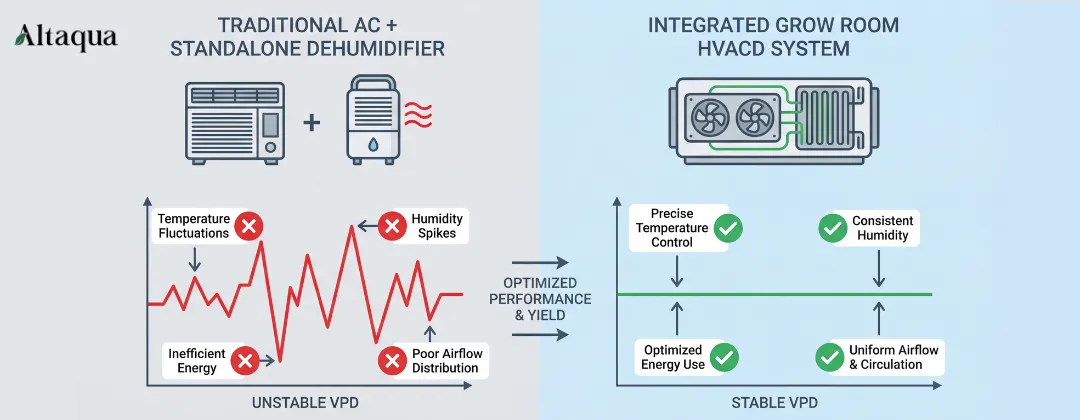

Why Traditional AC + Standalone Dehumidifiers Can’t Keep VPD Stable in Veg

Most growers start out with an AC-and-dehumidifier setup… until they start running into real problems.

➤ Problem 1: AC lowers temperature and humidity at the same time

Trying to hold 70% RH?

Five minutes of AC runtime and you might drop to 55%.

➤ Problem 2: The dehumidifier makes VPD for veg even worse

Lower humidity = higher VPD.

Higher VPD = more stress on the plant.

➤ Problem 3: Temperature and humidity control don’t sync

The AC follows temperature.

The dehumidifier follows humidity.

One pulls left, one pulls right → VPD swings all over the place.

➤ Problem 4: The more the system runs, the further VPD drifts from target

You try to correct it… and it gets worse.

This is not a growing issue.

It is a system-design failure.

Traditional setups cannot:

- Independently control temp & humidity

- Provide reheat

- Maintain high humidity without overcooling

This is exactly why veg-stage VPD overwhelms them.

Commercial grow rooms need something purpose-built:

- A real HVACD system designed specifically for stable VPD for veg, not repurposed home comfort equipment.

Why VPD Isn’t Even Consistent Within the Same Room: This Is an HVAC Design Problem

Almost every commercial grower has seen this scenario:

- Sensor A shows 72% RH

- Sensor B shows 58% RH

- Plants on the left grow fast

- Plants on the right get tip burn

- Top canopy is moist

- Bottom canopy is dry

This isn’t a VPD formula issue—it’s a microclimate issue.

Typical causes include:

- Uneven airflow distribution

- Poorly placed HVAC return

- Supply air causing hot/cold spots

- Dehumidifiers drying only one corner

- Temperature stratification (2–4°C difference between layers)

You cannot rely on a single wall sensor to represent the whole environment.

Commercial growers don’t need “average climate.”

They need uniform climate, which is essential for stable VPD for veg.

And that requires:

- A commercial grow room HVAC system with engineered airflow design.

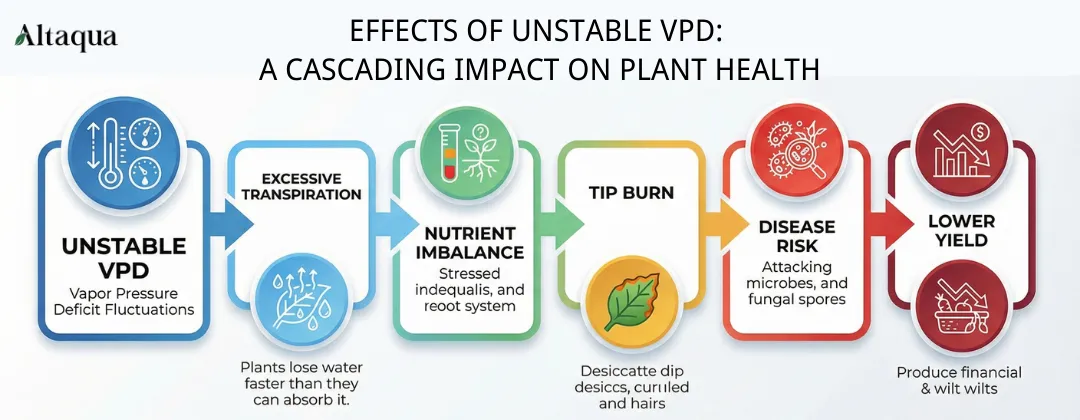

VPD Fluctuations Aren’t Minor Problems—They Turn Into Real Financial Losses

In the veg stage, even a small deviation in VPD sets off a chain reaction:

➤ If VPD is too high:

- Excessive transpiration

- Calcium deficiency

- Tip burn

- Reduced vigor

- Unstable transitions into flower

➤ If VPD is too low:

- Water film on leaves

- Explosive disease risk

- Reduced photosynthesis efficiency

- Impaired nutrient uptake

And in commercial cultivation, a “small fluctuation” doesn’t just affect one plant—it affects the whole crop:

- Lower yield, worse bud structure, downgraded product, higher operating costs.

That’s why experienced growers focus on climate control, not “equipment stacking.”

Why Professional Growers Eventually Choose Integrated Grow Room HVACD Systems

A real grow room HVACD system can do things no traditional AC-plus-dehumidifier combo can:

A true grow room HVACD system can do things traditional setups simply cannot:

✔ Independent temperature & humidity control

No more “cooling kills humidity” problems.

✔ Built-in reheat

Cool the room without crushing RH or VPD.

✔ High-powered dehumidification

Built to handle real grow room swings—from heavy irrigation to lights cycling on and off—without losing control.

✔ Engineered airflow uniformity

No more hot spots or damp corners. Air moves evenly, so VPD for veg stays consistent across the entire room, not just near the sensors.

✔ Designed for sealed grow rooms

These are the environments where VPD stability isn’t optional—it’s mission-critical.

✔ Adaptive response to fast load changes

Lights flip, heat jumps, irrigation hits—and the HVACD reacts in real time, automatically.

Bottom line:

A professional HVACD system turns VPD for veg into something stable, predictable, and actually profitable.

Conclusion: In commercial cultivation, knowing VPD isn’t enough—being able to control it is what really matters.

On paper, VPD for veg looks like just another growing metric. Something you track, maybe adjust now and then.

In real commercial rooms, though, it’s more like a stress test. It shows you how well your HVAC actually performs—how tight your temperature control is, how steady your humidity management is, whether your airflow design really works, and how fast the system can react when loads change suddenly.

When VPD stays stable, everything else tends to fall in line. Growth evens out. Yields become more predictable. Profits stop swinging with the climate.

And that’s why experienced growers see it clearly: control the climate, and you control the profit. The grow room HVAC system sits right at the center of that equation.

FAQ

1、Why does VPD for veg keep fluctuating even when I'm “doing everything right”?

Honestly, it’s rarely the grower’s fault. VPD for veg is extremely sensitive—lights come on, temps jump, humidity drops… then irrigation hits and everything swings the other way. Even different corners of the same room can show completely different VPD values.

And that’s the point: these swings don’t really come from “bad technique.”

They come from the HVAC system struggling to keep temperature and humidity in sync.

If your AC cools too aggressively or your dehumidifier overworks, VPD shoots out of range fast.

So the issue isn’t usually your growing—it’s your climate control setup not being designed for true VPD stability.

2、Why can't a normal AC and a standalone dehumidifier keep VPD stable during veg?

Because they’re basically fighting each other the whole time.

The AC cares only about temperature.

The dehumidifier cares only about humidity.

So during veg—when humidity has to stay pretty high—these two systems push the room in opposite directions. AC runs for a bit → humidity crashes. Dehumidifier kicks in → VPD climbs even more.

That’s why VPD for veg becomes so unpredictable with these setups.

You need a system that can control temperature and humidity independently, not two machines pulling left and right at the same time.

3、What actually helps keep VPD for veg stable in a commercial grow room?

What really works is an HVACD system built for controlled environments—not something pieced together from home-use AC units.

A purpose-built grow room HVACD system can:

- manage temperature and humidity separately

- add reheat so cooling doesn’t kill your RH

- maintain airflow evenly so microclimates disappear

- react quickly when lights, heat load, or irrigation change

That combination is what finally keeps VPD for veg steady instead of bouncing all over the place.

At the end of the day, stable VPD isn’t luck—it’s engineering.

Share with your friends:

Popular Blogs on Altaqua:

Download Catalogue