How Reheat Coil for Dehumidification Solves Hidden Grow Room Problems

Updated: June 27, 2025 · 18 min read

Have you ever experienced a problem like this? At night, humidity in the grow room spikes. When the plant lights turn off, the temperature drops. This disrupts the planned VPD balance. As a result, cannabis may grow abnormally or face disease risks. These small issues come from one main problem: unsynchronized temperature and humidity control.

Many growers don’t realize the hidden risks until they face crop losses. That’s where a reheat coil for dehumidification comes in. Without it, your dehumidifier may be pulling out moisture, but also leaving your grow room too cold—throwing off the whole balance your plants rely on. A reheat coil for dehumidification helps restore that balance by stabilizing the temperature immediately after moisture is removed.

This blog will take you on an in-depth look at how a reheat coil for dehumidification works in a grow room system. Using a reheat coil for dehumidification isn’t just about fixing humidity. It’s about keeping your cannabis healthy, your VPD stable, and your entire grow environment in sync. If you’ve been relying on standard dehumidification, it might be time to rethink what your plants really need.

What Triggers the Question: Why Consider Reheat Coil for Dehumidification?

In many grow rooms, many people don't initially consider a “reheat coil for dehumidification” solution. Most dehumidification systems focus mainly on "water removal." They just pull moisture out of the air.

However, that's where the problems begin.

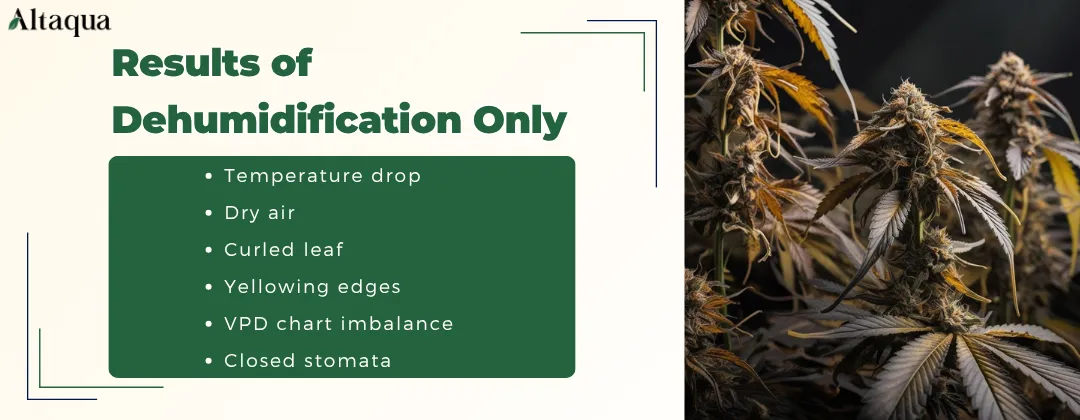

Dehumidification Alone Can Cause Trouble

Many growers have faced a time when the dehumidifier lowers humidity. But then, the environment gets colder, especially at night or after the lights go out. When the humidity drops, the temperature is pulled down as well. You may think “there's nothing wrong with a little dry air”, but that's not what cannabis thinks.

Lowered Temperature Disrupts VPD Balance

VPD (Vapor Pressure Difference) is key for cannabis. It affects how the plant absorbs water, transpires, and takes up nutrients. It is not only dependent on humidity, but also highly dependent on temperature. Lowering humidity with a dehumidifier can also lower the temperature. This change will affect the VPD value, too.

This change doesn’t wait for the cannabis to adjust. It affects how stomata open and close, how leaves transpire, and how roots take up water. After the lights go off, the air cools quickly. This can increase the VPD imbalance.

Fluctuating Transpiration Affects Nutrient Uptake

If the transpiration rate is erratic, the cannabis plant will struggle to take in water and nutrients consistently. This fluctuation may not bring about a noticeable ask kick in a short period of time. In the long run, this can impact cannabis growth. It may affect the thickness of stems and leaves. In severe cases, it can cause salt buildup in the roots and burns on leaf edges.

Most of the "abnormal behavior" you notice comes from failures in environmental control. It's not usually just one pest, disease, or variety issue.

Why Temperature Matters After Moisture Is Removed?

If you think that dehumidification is the same as “drying”, you may only have half the picture. In the modern growing environment, temperature and humidity are an inseparable pair.

True Environmental Stability Requires Both Temperature and Humidity Control

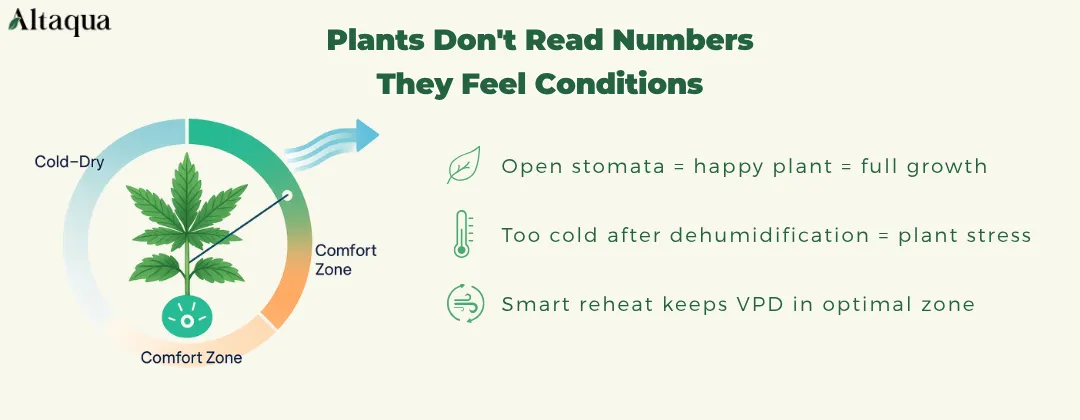

Picture how cannabis feels in a cold space after dehumidification. It's uncomfortable, stiff, and uninspiring, similar to being in a cold, damp basement. And that's why the reheat coil for dehumidification plays a key role here. It doesn't just heat the air; it warms it slightly after removing humidity. This brings the temperature to a level that cannabis can adapt to more easily.

The “temperature and humidity bistability” that results from this approach is truly a controlled environment. Your HVAC system isn’t just a dehumidifier anymore. It’s now an environmental coordinator. It helps your cannabis vaporize at different stages.

Crop Response to “Perceived Conditions” Is More Sensitive Than You Think

Don't underestimate cannabis' ability to sense the details of the environment. Cannabis senses “temperature + humidity” better than we do. While we might say, “it’s a bit stuffy in here,” the plant is already adjusting its stomata. It reduces transpiration and slows absorption to cope with the conditions. Many cannabis growers notice leaf droop and humidity spikes at night. They may also face powdery mildew and mold. This happens when air temperature can't keep up with humidity.

Consider the reheat coil for dehumidification. It can help create a healthier and more stable growing environment. It's not just extra gear. It's a key addition to the often overlooked part of standard dehumidification systems.

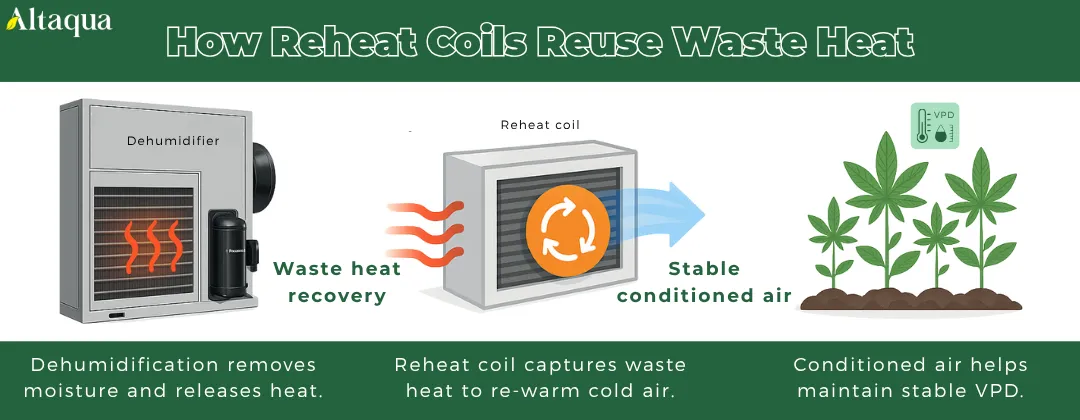

How Reheat Coil for Dehumidification Works in a Dehumidification System

The key to solving the fluctuating environment in the grow room is “Dehumidification + Reheating.” To understand this solution, start by learning how the reheating coil works. Reheating isn't about making the room hot. It aims to return the temperature to a balanced point. This balance of temperature and humidity helps cannabis with transpiration, respiration, and metabolism.

Simple Physics Behind Reheat

To understand how a reheating coil works in a grow room, we must first look at the basic principles of thermodynamics. This is not a complex engineering theory, but a simple and efficient way of “reusing energy”. We need to understand reheating to see how it fixes VPD fluctuations and temperature or humidity imbalances in growing. Let's dismantle this principle from two perspectives.

What Is a Reheat Coil for Dehumidification?

A reheat coil for dehumidification is a heat exchanger. It is installed at the air outlet of a dehumidification system. Its job is to warm the cooled, dehumidified air. This makes the “cold air” more suitable for marijuana after humidity is removed.

Why is this step important? Because the dehumidification process is essentially a cooling process. As air flows through the evaporator coil, moisture condenses. This causes the air temperature to drop. Sending this cooler air into the grow room will cause a sudden temperature drop. This can disturb the VPD balance for the cannabis.

The reheat coil for dehumidification is there to warm up this air to a more appropriate point. It doesn't “heat up” the air. Instead, it returns the temperature. This helps keep the environment in the right range as humidity drops.

How to Repurpose Heat That Would Otherwise Be Wasted

A great reheat system uses "heat recovery" to warm up instead of electric heaters. When an HVAC system is dehumidified, the compressor and condenser generate a lot of heat. This heat would have been eliminated or dissipated for nothing. The reheat coil for dehumidification sends heat into the coil. This process gently warms the air after it leaves the cooling section. Our Altaqua Grow Room HVAC System utilize this highly efficient hot gas reheat feature.

This “recycling” process has two distinct benefits:

The first is energy efficiency. You don't need to use additional energy to heat the air.

The second is smoother. Recovering heat doesn’t make the temperature rise too high. Instead, it keeps it steady within the set range. This creates a feeling of “cold but not cold, dry but not dry.”

How Reheat Coil for Dehumidification Makes a Difference in Grow Rooms?

Once you grasp how reheat works, you may wonder: How does it help in real-world growing environments? Reheat impacts the cannabis' transpiration rhythm, growth efficiency, and affects their yield and quality. Here we will look at two key aspects of how reheat is specifically involved in optimizing the entire growing process.

Maintain Stable VPD and Avoid Diurnal or Phase-Based Swings

VPD stabilization is crucial in cannabis cultivation. A stable VPD is not just calculated; it is controlled. Traditional dehumidifiers can experience sudden temperature drops at night or when the lights go out, leading to a spike in VPD. The core value of reheat coil for dehumidification is to bring the environment back on track at these critical times.

When the lights go off, evaporative cooling slows down. This causes air humidity to rise. Then, the dehumidification system activates, cooling and drying the air. However, without the reheat coil, the temperature also drops. This leads to a messed-up VPD. The transpiration rate goes down, water collects on leaves, or even condenses. This increases the risk of disease.

With a reheating coil, the air is gently warmed after dehumidification, avoiding a sudden drop. This way the VPD stays within the set green zone. Environmental switching between day and night, between lights on and off becomes smoother.

Coordinate with Lighting and Irrigation to Sustain Growth Efficiency

In the cannabis growing cycle, lighting and irrigation stick to a strict schedule. The reheating coils help to “protect” these rhythms.

For example, a dehumidification system intervenes when air humidity rises rapidly after irrigation, but if it is not synchronized with warming at this time, cannabis leaves may close their stomata due to the low temperatures, reducing transpiration and thus affecting water circulation. But when paired with a reheating system, the ambient temperature is not pulled down by dehumidification, and cannabis can still maintain its normal metabolic rhythm.

Similarly temperatures may fluctuate slightly when lighting intensity changes. If the dehumidification system adjusts reheat output based on lighting, it helps create better conditions for cannabis growth. This means improved temperature and humidity levels. As a result, growers can expect thicker stalks, healthier roots, and higher yields.

When Is Reheat Coil for Dehumidification Actually Needed?

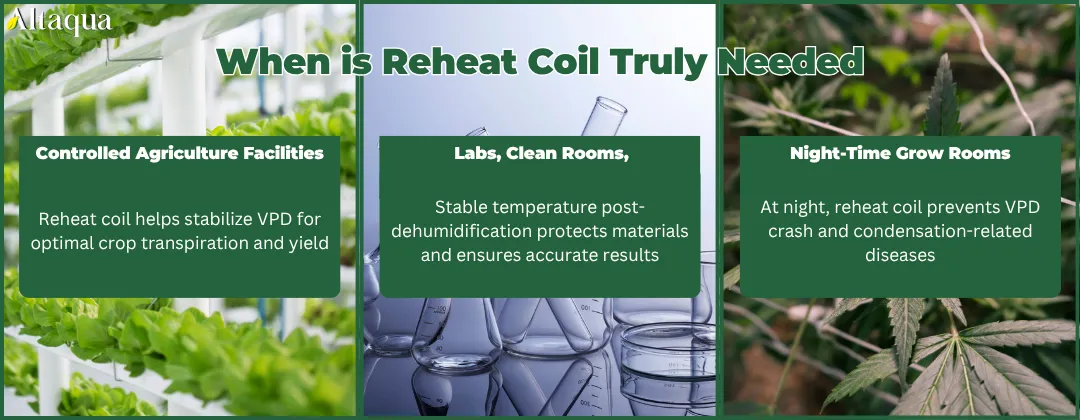

Reheat coils are not “standard” in every dehumidification system. For ordinary homes or commercial spaces with low environmental requirements, simple cooling and dehumidification is sufficient. But when it comes to places with stringent environmental control requirements and humidity fluctuations that can directly affect product or crop quality, reheating coils go from being “optional” to “required”. Especially in spaces where specific temperature and humidity combinations must be maintained, and where day and night operation fluctuates dramatically, the role of the reheat coil for dehumidification is often a critical part of stabilizing the entire system. Let's take a look at a few typical scenarios.

Controlled Agriculture Facilities

Modern Controlled Environment Agriculture (CEA) relies more on climate than traditional farming does. In cannabis cultivation, it’s important to balance air humidity, temperature, and VPD. These factors need to stay within a narrow range. Too much dehumidification without heating can cause low temperatures. This can disrupt the transpiration rhythm of cannabis. Using a reheat coil for dehumidification helps keep the temperature steady. This way, the whole climate system can run smoothly. It also prevents stress and yield loss caused by changes in the environment.

In greenhouses and vertical farms, humidity levels can vary by zone. Reheat coils allow each zone to be fine-tuned. You can adjust the temperature and humidity in specific areas. This flexibility helps commercial growers maximize their yields all year long.

Labs, Clean Rooms, Archives

In some special places such as laboratories, semiconductor workshops, sterile rooms, and cultural relics storage warehouses, the requirements for humidity and temperature are equally high. Dehumidification alone can easily lead to a space that is too cold, and too cold may affect experimental results or lead to damage to materials due to expansion or contraction. Artifacts, for example, are particularly sensitive, and the slightest instability may result in mold or structural deterioration.

In such environments reheat coil for dehumidification is not only a climate control tool, but also a guarantee of stable operation. It ensures that the air does not “cool down” after the moisture is removed, but is reheated to a stable, suitable temperature. This balance of temperature and humidity is essential for the long-term safe operation of the space and to avoid frequent energy wastage.

Grow Rooms Facing Night-Time or Lights-Off Humidity Surges

This is one of the most common and “overlooked” issues in marijuana cultivation. During the day, when the lights are on, the temperature rises, the air can hold more water vapor, and the VPD is relatively stable. At night, however, when the lights are off, the temperature drops rapidly, the air becomes more saturated, and the humidity level soars. At this point, if you don't dehumidify and supplement heat in time, not only will the VPD value be broken, but condensation on the leaf surface and water vapor accumulation will even induce diseases such as mildew and downy mildew, which will have a direct impact on the harvest.

The use of a dehumidification system equipped with a reheating coil allows the equipment to maintain a stable temperature and humidity even at night: the compressor removes excess water vapor, and the cooled air is subsequently reheated through the coil to maintain the air in the temperature range required for planting. This smoothes out the diurnal fluctuations and ensures that the plants are kept in a comfortable, healthy climate even during the “rest of the night” phase.

Is Reheat Coil For Dehumidification a Smart Investment?

Many cannabis growers are hesitant to configure their HVAC systems with the option of “reheat or not”. It may sound like an add-on, and it may increase the initial investment and operating energy consumption. But it's easy to overlook the long-term value of a reheat system when you're only looking at the immediate cost of the equipment or your electric bill.

In actual operation, a well-designed reheating coil system will not significantly increase your operational burden, but may through the “temperature and humidity balance”, “VPD stabilization”, "system load shedding Instead of significantly increasing your operational burden, it may bring considerable hidden benefits through “temperature and humidity balance”, “VPD stabilization”, “system load reduction” and other means.

It's more than just a tool. It's a smart investment. It boosts planting efficiency and helps keep product quality steady over time.

Does Reheat Always Mean Higher Energy Use?

Many people think "reheating" means "power consumption" and "energy waste." However, this view is not correct. Indeed, reheating will consume some additional heat, but the key lies in where the heat comes from, and whether its role is necessary.

Modern dehumidification systems use waste heat recovery in reheating. Instead of needing extra heaters, these systems use heat from the condenser. This heat comes from the dehumidification process and helps warm up cold air. This process adds little or no extra energy. It smooths the temperature of the discharged air. Also, it helps avoid the environmental issues linked to "overcooled air supply."

This stable heat and humidity output in the grow room is critical for VPD management and plant health. Instead of energy consumption, it is a “second use” of energy efficiency optimization.

When Reheat Saves You Money in the Long Run

Instead of worrying about whether reheating will “cost more money”, it is better to think about it from another angle: in what ways, it is actually “help you save money”.

Reducing Crop Stress and Improving Yield Is a Hidden Saving

For a valuable crop like cannabis, even one change in VPD, moisture buildup, or leaf condensation can impact transpiration and nutrient absorption. When cannabis faces ongoing stress, it grows slower and changes color later. It can also suffer from moisture damage like gray mold and downy mildew. This impacts both quality and yield.

A reheat coil is important because it quickly restores temperature after dehumidification. This helps keep the ideal VPD zone. It can stabilize the climate even in tough times like "lights out," "low load," and "high humidity at night." This “detailed stabilization” of the climate is often key to the final yield of a single plant and batch consistency.

In the long run, a stabilized growing system results in fewer diseases, lower plant culling, and higher dry flower conversion. These seemingly “invisible” gains are your real profit margin.

Lowering HVAC Cycling Frequency Reduces Maintenance Costs

Another hidden advantage of reheat coils is that they slow down the start/stop frequency of the main HVAC unit.

When there is no reheat unit, the system must repeatedly switch between “over dehumidification” and “make-up”. This increases energy use. It also makes the compressor, fans, and controllers start and stop often. This can lead to more wear and tear, which shortens the equipment's life.

Dehumidification systems with reheating adjust air supply temperature accurately. They keep the humidity level steady. This setup prevents constant switching between cooling and heating. As a result, the HVAC system operates more smoothly. This means less maintenance, fewer consumables, and longer service life. In the long run, saving on maintenance gives a big operational edge that you shouldn't overlook.

How to Choose the Right System with Reheat Capability

Deciding to configure a reheating system for your grow room is only the first step, what really counts is - how to pick the right solution. System designs affect how well temperature and humidity are controlled. They also impact how easy the system is to use and how reliable it is over time. If not chosen well, you won't get the right dehumidification and temperature control. This can also raise operational costs and maintenance risks.

To see if a reheat system is “right for you,” consider these points: Does its design match your current HVAC system? Does the control logic integrate seamlessly? Is it easy to install and maintain? We also need to compare reheating with other dehumidification methods. This will help us see its energy-saving benefits and limits.

Integrated vs. Add-on Reheat Solutions

There are two main types of reheating solutions on the market. One is integrated reheating systems. The other is external heating unit retrofit solutions.

Integrated systems are HVAC setups where the reheat module is designed to fit inside the main system. In these systems, the air ducts, control logic, and duct layout work together seamlessly. This type of system is suitable for users who are planning a new grow room or a complete upgrade of an existing system. Its advantages are precise control, quick response, compact size, and a compatible system that improves energy efficiency.

External retrofits are often used in grow environments with existing HVAC systems. They help tackle humidity control issues. Users can temporarily increase reheat capacity by adding an electric heater or hot water coil. This approach is flexible and cost-effective. However, it often leads to control delays, weak equipment coupling, and low energy efficiency.

To achieve long-term stability and precise climate control, focus on a native integrated reheat system. If you have a tight budget or need to boost humidity quickly, think about an external retrofit as a temporary fix.

Can It Integrate with Your Control System?

The performance of a reheat system is dependent on precise control logic. A good reheating solution should easily link to your existing environmental control system. This includes sensors for temperature and humidity. It also covers VPD monitoring, zone control, and strategies for night dehumidification.

Use an advanced control platform, like a central controller with VPD dynamic calculations. Then, prioritize a reheating system that supports protocols like MODBUS and BACnet. This helps ensure smooth information exchange. Otherwise, it is difficult for the most efficient hardware to realize its real advantages.

If your control system is basic, consider buying reheating equipment with a built-in control module. You can also check with your HVAC system supplier to make sure everything works together later.

Is It Easy to Install and Maintain?

Many grow farms have limited space for HVAC systems. So, the reheat system size, wiring layout, and maintenance area must be planned carefully.

Integrated equipment is easy to install. It needs just one commissioning to start automatic operation. Maintenance is also simple later on. External retrofit equipment may need extra power leads, heating protection devices, and air duct changes. This can lead to a longer construction cycle. Also, operations may face delays in “temperature and humidity separation” control.

When choosing reheating elements like electric heaters or heat recovery heat exchangers, consider their long-term operation. Dust, corrosion, and scaling can be problems. Regular maintenance and ease of cleaning are also key factors to think about.

Compare with Other Dehumidification Methods

Before choosing a reheat coil for dehumidification system, understanding the advantages and disadvantages that differentiate it from other common dehumidification methods will help you make a more cost-effective choice.

Reheat Dehumidification vs. Standard Dehumidification: Which Is More Efficient?

The principle of standard dehumidification (i.e. cooling dehumidification) is simple: the air is cooled by an evaporator and the moisture is condensed and discharged. But there's a common issue with this method: the air temperature can be too low. This makes the air supply cold, disrupting the VPD balance in the grow room.

Reheating dehumidification warms up cooled air. This helps reduce humidity while keeping the air temperature just right. This method works well in places like marijuana cultivation. Those environments are sensitive to temperature and humidity levels.

Reheating might look like it uses extra energy, but it helps stabilize the climate. This benefit is much greater than the energy it consumes. This is especially true when humidity rises quickly at night after the lights go out.

Electric Reheat vs. Heat Recovery Reheat: Which Is More Efficient?

Electric heating is direct and quick. It’s easy to control, making it great for small systems that don’t change load often. Its energy efficiency is often low, especially in winter or in places with high electricity prices. This leads to high operating costs.

Heat recovery reheating is more energy efficient. It sends heat from the condenser back into the air. This allows for heating after dehumidification without using extra energy. This method is now seen as the most energy-efficient way to reheat. It works well for high-frequency use in grow rooms.

If the project budget is tight and power capacity is low, start with electric heating. Then, upgrade to heat recovery equipment when you can.

|

Comparison Criteria |

Standard Dehumidification |

Reheat Dehumidification (Electric) |

Reheat Dehumidification (Heat Recovery) |

|---|---|---|---|

|

Dehumidification Capacity |

Strong |

Strong |

Strong |

|

Supply Air Temperature Control |

Weak – often delivers cold air |

Good, but with higher energy use |

Good, with higher energy efficiency |

|

VPD Stability |

No |

Yes |

Yes |

|

Energy Efficiency |

Moderate |

Lower |

Higher |

|

Control System Integration |

High |

Needs additional control modules |

Often integrated with system |

|

Initial Investment Cost |

Low |

Medium |

Higher (but with long-term benefits) |

|

Maintenance Complexity |

Simple |

Moderate (check electric components) |

Moderate (maintain heat exchange coils) |

|

Best Use Case |

Environments with low humidity sensitivity |

Small projects needing better humidity control |

Grow rooms requiring stable VPD |

Altaqua HVAC with Reheat Coil For Dehumidification Is a Smart Choice for Growers

Altaqua Grow Room HVAC System focus on reheat coil for dehumidification as a crucial technology, not just an extra feature. They have years of experience in high-end indoor growing. So, they provide reheating and dehumidification systems made for cannabis cultivation. We not only focus on the data of temperature and humidity control, but also on the long-term stability of the system and the simplicity of operation.

Designed for Grow Room Realities

In the real world of growing, environmental conditions change rapidly. Altaqua Grow Room HVAC System has a reheating coil for dehumidification. It controls the supply air temperature during dehumidification. This helps prevent “cold damage” or dew point condensation from very cold air. The system also considers load changes and day/night cycles in grow rooms. This helps keep a steady VPD range despite changing environmental conditions.

Smarter Reheat, Less Guesswork

Traditional reheating systems need manual adjustments. This can lead to under- or over-heating, upsetting the environment. Altaqua solves this with smart control logic. It checks indoor temperature and humidity in real-time. Then, it uses the VPD algorithm to adjust the reheating coil as needed. Now, you don’t have to calculate the supply air dew point by hand or change the setpoint often. The system handles this step for you automatically. Less manual intervention and lower error rate bring a healthier and more stable plant growing environment.

Integrated, Not Added Later

Many growers overlook reheat at first. They often wait until humidity control issues arise before thinking about retrofitting. Altaqua's reheat function is built into the system from the start. This means no extra wiring or outside control is needed. The machine's control is unified. This prevents multiple controllers from “fighting” each other. As a result, overall efficiency improves.

Real Savings, Beyond Energy Bills

While the Altaqua system is inherently energy efficient, the real “savings” are not just in the electricity bill. For example:

1.Reduced crop yields due to environmental fluctuations and increased yields per unit area;

2.Reduced incidence of disease and less frequent use of pesticides and nutrient compensation;

3.Reduced cost of human involvement in equipment commissioning and risk of error.

These “hidden savings” are hard to measure right away. But they directly affect a growing program's long-term profits. Altaqua HVAC systems meet your needs. They help you get better and more steady returns in the tough growing industry.

Conclusion

For a humidity-sensitive grow environment like a cannabis grow room, reheat coil for dehumidification is essential. It's not just optional; it’s the key infrastructure that helps stabilize and control conditions. Without stable humidity, VPD can't be controlled. If air temperature isn't accurate, transpiration won't be stable either. At night or during low load, a single dehumidification system can make the air too cold. This can quickly drop leaf temperature or even lead to condensation, which stresses the plant. Reheating helps fill this gap. It lets you remove moisture from the air without making it too cold. This protects the rhythm and stability of crop growth.

If you struggle with VPD swings, humidity-related diseases, erratic yields, or constant equipment restarts, reheat coil for dehumidification might be the solution you haven’t tried. It’s likely to help. It can help you take your growing environment from “reactive” to “active”. Altaqua Grow Room HVAC System have smart reheating features. They make it easy to set up and maintain. Plus, they help you avoid compatibility and energy issues found in traditional aftermarket systems. In the end, it's not just the electricity bill that's going down, it's the whole logic of growing that's becoming more stable and easier.

FAQ

1、I already have dehumidification in my grow room, do I need to reheat the coil?

If your grow room has low supply air temperatures during dehumidification, you may notice issues like cold leaf temperatures at night, unstable VPD, plants being more prone to disease, or slow growth. In this case, reheating is essential. It can rewarm the air after dehumidification. This keeps humidity and temperature control in sync. As a result, it creates a better micro-environment for crop growth.

2、Does reheat function mean higher energy consumption?

Not necessarily. A well-designed reheating system can save energy. For instance, using a heat recovery system instead of electric heating boosts dehumidification efficiency, too. Reheating helps HVAC systems by lowering start-ups and stops. This can extend equipment life and save energy over time.

3、Should I choose an integrated reheat system or a post-installed heating unit?

An integrated system is the better choice. It looks at airflow, heating capacity, and the control system early in the design. This leads to more stable and smarter regulation. Post-installed equipment can face issues like poor compatibility and uncoordinated control. It often has low energy efficiency. Over time, this can lead to higher operation and maintenance costs.

4、What is the biggest difference between reheat dehumidification and normal dehumidification?

The biggest difference is the ability to control the “supply air temperature”. Regular dehumidification systems mainly remove moisture from the air. In contrast, reheat dehumidification not only does that but also adjusts the air temperature. This helps create a better crop environment. It stabilizes VPD, reduces plant stress, and boosts overall yield and quality.

Share with your friends:

Popular Blogs on Altaqua:

Download Catalogue