Sensible Heat Factor: Not Just for Engineers, But Essential for Cannabis Growers

The Sensible Heat Factor has been quietly affecting the results of many marijuana growers without them even realizing it. You might feel your air conditioner is doing a good job. But when you enter a room, it can feel humid and stuffy. Or maybe the temperature seems just right, yet your marijuana is still yellowing and wilting. These issues all connect to the Sensible Heat Factor.

Have you ever wondered how many dehumidifiers you need for the right humidity? Or why your marijuana isn’t acting as expected, even after doing everything right? This article will help clear up your confusion. The Sensible Heat Factor might sound technical, but it’s key to a stable growing environment and better yields.

We will explain the Sensible Heat Factor, how it works in HVAC systems, and how to control it in grow rooms. This will help you achieve the best temperature and humidity balance. Whether you're a marijuana grower or a technician, this article provides the answers you need.

Real Grower Problems Tied to Sensible Heat Factor

In managing a marijuana grow room, problems can be tricky. You might think the issue is with equipment, the controller, or even the plants. But often, it’s linked to a factor you might overlook: the Sensible Heat Factor. It’s not as clear as a thermometer. It’s also less common than a humidity meter. Still, it shows if your environment is truly balanced.

Why Is My AC Cold, But the Room Feels Wet?

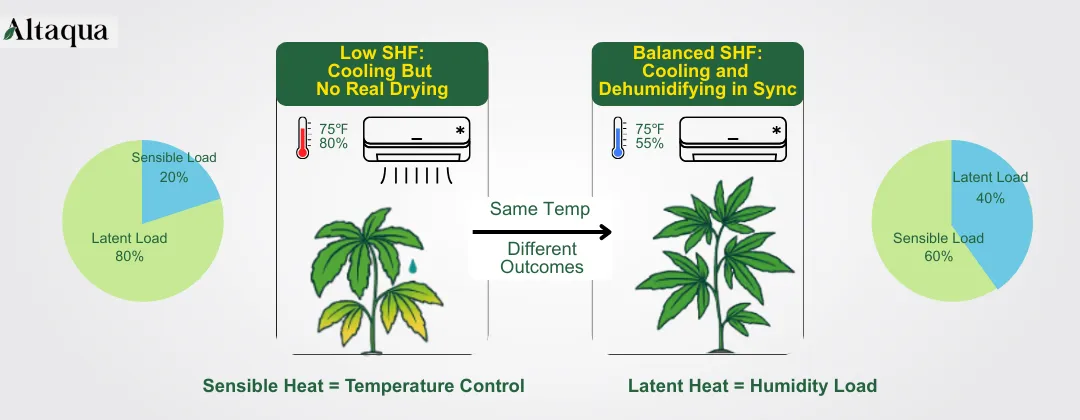

Many cannabis growers feel confused. Even when the air conditioner blows cool air, the room can still be very humid. This happens because most air conditioning systems focus on "human comfort." They mainly cool the air, which means they handle "sensible heat" but not humidity.

But a marijuana grow room has a different heat load to deal with. Besides cooling, it's crucial to remove moisture from the marijuana's vapor. This is the "latent heat" part. If the system fails to manage this moisture, the space gets more humid. You feel uncomfortable, even in low temperatures. Plus, high humidity stresses the roots and leaves of the marijuana plant.

Why Are My Plants Showing Signs of Stress Despite Perfect Temps?

Some marijuana growers use guides to keep temperatures in the "golden zone" of around 75°F. They also refer to VPD charts. Still, many find their leaves turn yellow, curl, and stop growing. Some growers meditate but still can't fix this issue.

Growers shouldn't just think about the temperature now. They need to focus on what it means. Specifically, they should check if the temperature and humidity ratio match.

If the sensible heat factor is off, the air can hold too much moisture. This can hurt transpiration and nutrient transport in cannabis. Just like people in hot, humid weather can get dehydrated, plants can "suffocate" too. This stress can last a long time and may slowly lower both the yield and quality of marijuana.

Why I Keep Adding Dehumidifiers, But Nothing Works?

When humidity rises in the grow room, many marijuana growers often rush to buy a dehumidifier. If one doesn’t work, they get two. If two fail, they might buy two more. Yet, this often leads to high humidity levels and soaring electricity bills.

Why is this?

The key is in the sensible heat factor. If it's not designed well, it’s like treating a headache with a foot remedy. The dehumidifier just fixes a symptom. It doesn’t tackle the root cause. The AC system may not handle latent heat well, the airflow might be poor, or the grow room could be miscalculated. Adding more equipment won't solve these issues.

What Is Sensible Heat Factor in Grower Terms?

In the paragraph above, one word that comes up a lot is sensible heat factor. What is sensible heat factor? Sensible heat factor (SHF) is key, though often ignored. It shows if your HVAC system focuses on "cooling" or "dehumidifying." Let’s begin with the basics.

The Difference Between Sensible and Latent Heat

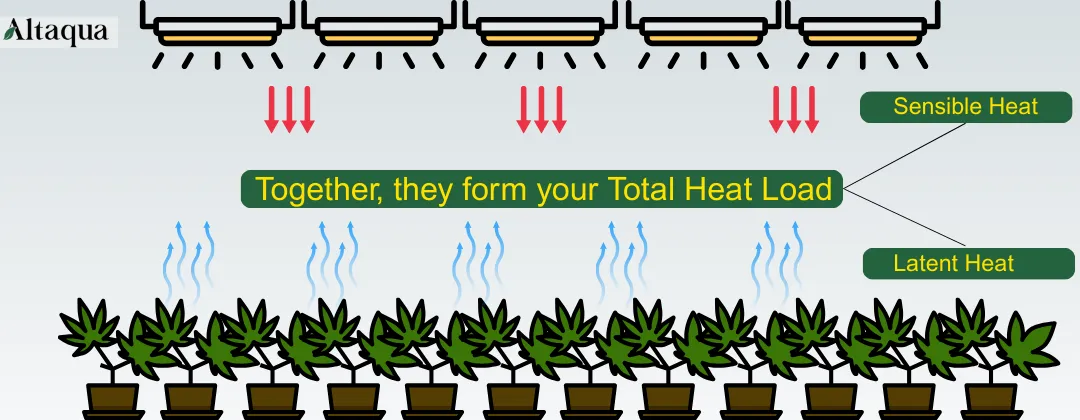

To grasp SHF basics, we must first clarify two key ideas: Sensible Heat and Latent Heat. They are like two sides of the same coin, forming the "heat load" of your grow room. Understanding their roles helps explain why some rooms stay humid, even when cooled.

Sensible Heat – What You Feel

"Sensible" means "perceptible." When you enter a grow room and feel cooler air, that's sensible heat at work. Sensible cooling happens when the temperature changes directly. For example, if you set the air conditioner to 72°F, and the room drops from 78°F, that’s sensible cooling. In simple terms, sensible heat affects your body temperature.

Latent Heat – The Hidden Moisture Load

Latent heat isn't something you can directly feel. It's hidden in water vapor in the air. For instance, plants release water when they're in light. You might not feel hot right away, but that moisture needs to be removed by dehumidification. This hidden heat connects to humidity, mold, and disease.

How Is Sensible Heat Factor Related to HVAC Systems?

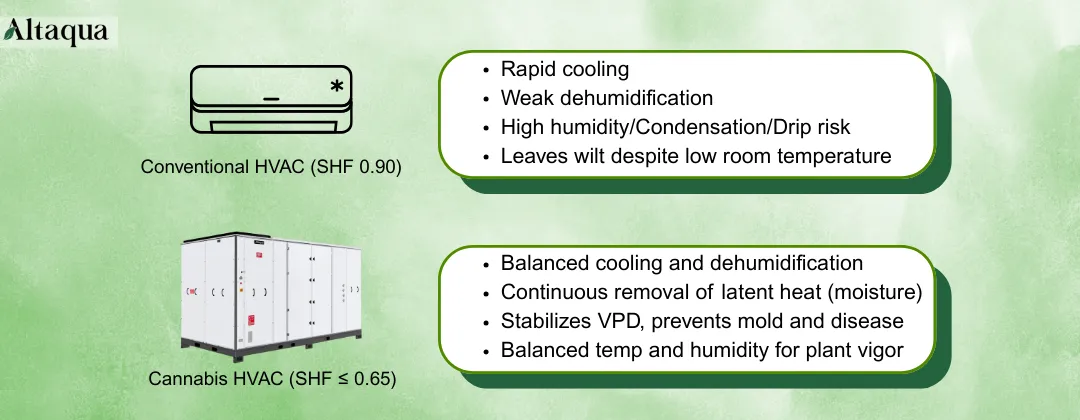

SHF is key to understanding HVAC system performance. It shows if the system prefers to cool or dehumidify. A good HVAC system should manage both types of heat. Let’s explore how SHF measures cooling and dehumidification performance in HVAC systems.

SHF as a Performance Metric

The Sensible Heat Factor (SHF) is a ratio. It shows how well a system can manage sensible heat compared to the total heat load. You can calculate it using this formula:

SHF = Sensible Heat Load / (Sensible Heat Load + Latent Heat Load)

This may seem technical, but here’s a simple example: An HVAC system removes 90 units of sensible heat (cooling air) and 10 units of latent heat (water vapor) every hour. So, its SHF is 90 / (90 + 10) = 0.90.

If the SHF of an HVAC unit is 0.90, that means 90% of its capacity cools. Only 10% is for dehumidification.

A system like this works well in an office, home, or store. These spaces care more about temperature than humidity. However, it’s a different story in a marijuana grow room. Plants breathe and release moisture through transpiration and photosynthesis. This adds a lot of humidity to the air. If the HVAC system can’t handle all that water vapor, humidity can rise quickly. This can cause diseases and other growing issues.

Balancing Cooling and Dehumidification

An HVAC system for a marijuana grow room needs a lower SHF value. This is important because it has to do two jobs at once:

·Keep the air temperature in the right range for cannabis

·Continuously remove the water vapor produced by cannabis transpiration

If the unit only cools and doesn’t take out humidity, the air can get damp. This makes the space feel heavy and can cause water to drip on walls and vents. You might also see that marijuana leaves stay wet. Over time, this can lead to mold issues.

A system with a lower SHF might seem to "not cool down as fast," but it actually removes moisture from the air. This is key for a marijuana grow room to operate smoothly and steadily.

Cannabis-specific HVAC systems have special dehumidification parts or improved condensate pans. These features help remove moisture while keeping temperatures from dropping too low. This focus on humidity control is what makes them different from regular commercial air conditioners.

Why Does SHF Matter for Cannabis Cultivation?

HVAC systems do more than just cool the grow room. They play a key role in growing marijuana, which is sensitive to changes in its environment. For cannabis growers, temperature and humidity matter. They need to work together. The Sensible Heat Factor (SHF) is the hidden force that helps them stay in sync.

Managing Temperature and Humidity Together

During growth, we often confuse "temperature" with "environment." Controlling temperature isn’t enough. The key is to understand how temperature relates to humidity. We refer to this as VPD, or Vapor Pressure Deficit.

VPD acts like the "respiratory pathway" for plants. It controls their transpiration. If it's too hot and humid, plants lose water fast and shut their stomata. But if humidity is high and temperatures are low, transpiration slows. Water can't escape, and root uptake stops.

So what does this have to do with SHF?

If your HVAC unit's SHF is too high, it's cooling too much and not dehumidifying. The room may feel cool, but humidity stays high. This misalignment affects the VPD, stressing the plants or causing them to wilt.

A system with the right SHF value and a good design can sync temperature and humidity. This helps stabilize your VPD range and keeps your plants healthy.

Optimizing VPD for Maximum Yield

What does a growing environment that is in the optimal VPD zone give you?

|

Benefits of Optimizing VPD |

Concrete Expression |

|---|---|

|

Faster Photosynthetic Efficiency |

Keeping an ideal VPD environment will boost flower density, odor, and color. This leads to a better quality and more productive crop. |

|

Deeper Root Development |

Moderate transpiration pressure helps roots absorb water effectively. This improves water and nutrient uptake, which supports plant growth. |

|

Higher Resistance to Stress |

Plants are more resilient. They handle temperature and humidity changes better. |

|

Stronger Flavors and Heavier Yields |

Keeping a good VPD environment helps boost flower density, odor, and color. This leads to a better quality and higher yield crop. |

The key to all this is whether you can create a stable system for temperature and humidity control. SHF is crucial in this process.

Think of SHF as an environmental "tendency," not a technical term. Do you want the system to cool more, or to dehumidify more? Choose the wrong option, and your grow room may suffer. Pick the right one, and VPD will stabilize, leading to higher yields.

In cannabis cultivation, SHF is essential. It's the key factor that works behind the scenes.

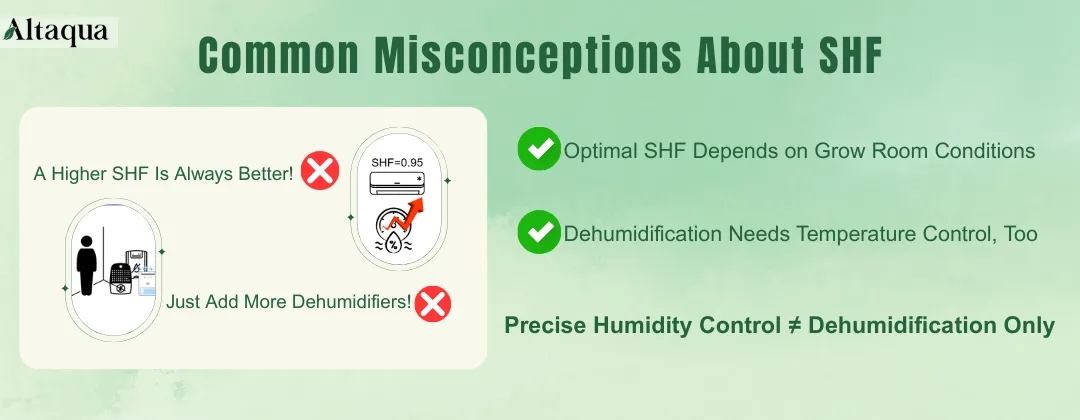

Common Misconceptions About SHF

SHF is a technical term, but many growers misunderstand it. Some chase high SHF without reason, while others overlook it entirely. Let's clear up these myths. We'll explore equipment choices and environmental management in a more scientific way.

Higher SHF Isn’t Always Better

Many people see a unit with an SHF of 0.95 and think it means "high efficiency." This idea holds true in homes or offices. Here, cooling is the main need, while humidity control is less important.

In a marijuana grow room, things change a lot. Cannabis needs stable humidity to thrive. If most of the system energy cools the room but can't dehumidify it enough, problems arise:

·The air humidity does not drop and the leaves are unable to transpire efficiently;

·Room temperatures are cool. This makes plants grow slowly. They can also get mold or face stress.

·The air conditioner runs for a long time, but the humidity problem can never be solved.

So what kind of SHF is appropriate?

For a grow space, the ideal SHF should be between 0.70 and 0.85, depending on your target VPD and stage of planting.Example:

|

Planting Stage |

Recommended SHF Range |

Control Focus |

|---|---|---|

|

Seedling Stage |

0.75–0.85 |

Gentle cooling and moderate dehumidification |

|

Veg Stage |

0.70–0.80 |

Enhanced dehumidification to maintain high VPD |

|

Flowering Stage |

0.65–0.75 |

Dehumidification priority to avoid mold and wet spot |

These medium SHF devices handle temperature and humidity well. They create a stable and safe microclimate for plants.

SHF Doesn’t Replace Full Environmental Control

SHF is important for figuring out how well an HVAC system dehumidifies. However, it's just one part of the whole environmental control system. A good SHF value helps balance cooling and dehumidification. Still, it doesn't show if the system is right for growing.

For a productive growing environment, use SHF as a base judgment. Don’t rely on it alone for purchasing decisions. Focus on whether the system adjusts heat load for different growth stages. It should also manage humidity to meet growing needs.

In short, SHF shows how the equipment behaves, like cooling or dehumidifying. However, it won’t tell you if the whole room is stable for plant growth.

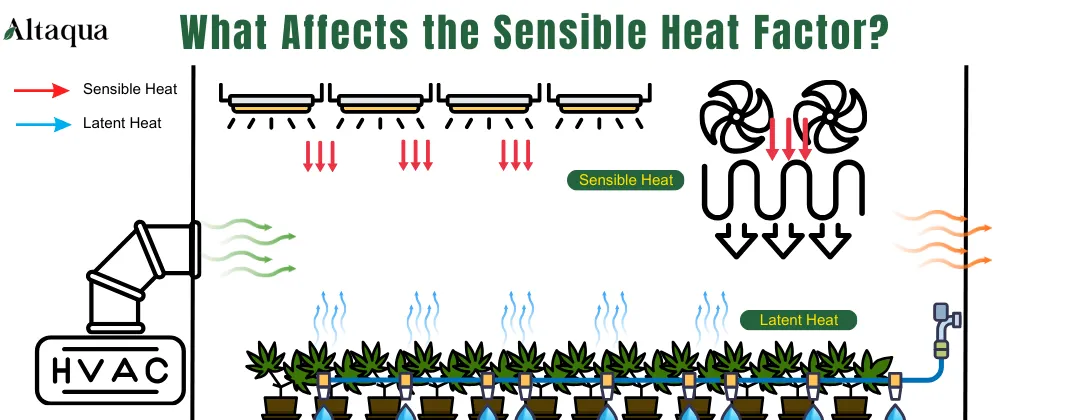

What Affects the Sensible Heat Factor?

The Sensible Heat Factor (SHF) isn’t a constant. It changes with different environmental factors and design conditions. This shows how well your grow room manages "temperature" and "humidity" right now. These factors help you find the right HVAC equipment for your cannabis grow room. It helps you enhance your environmental control strategy. This boosts system efficiency and increases crop yields.

Room Design and Equipment Load

A grow room isn’t a sterile lab box. It has light, wind, and a heat source. Plus, there’s constant water vapor. All these factors impact how well the system manages sensible and latent heat. This, in turn, affects the SHF when you run it.

Impact of Lighting and Fans

Lamps are definitely a big heat load.

High-power LED or HPS lights run for 12 hours a day. The room feels like an "electric stove." Fans and an electronic control box also generate heat. As a result, the heat builds up quickly, and latent heat isn't managed.

SHF is also rising. Is it sound efficient? No. Your system keeps "blowing cold air," but moisture collects on the blade. This buildup in the corner will cause problems eventually.

Equipment Placement and Airflow

The HVAC setup and return air paths greatly impact heat and moisture distribution in a room. If you place a high-efficiency dehumidifier in a dead space, it won’t work well. You'll just see reduced efficiency.

Airflow controls moisture movement. If the supply air focuses on the aisles and the return air is too high, moisture gets stuck in the middle of the plant. This trapped moisture can't escape.

A good setup lets cold, dry air flow through the entire plant layer like water. This removes all the vapor from transpiration. It keeps the system running smoothly and the SHF stable. On the other hand, bad airflow wastes electricity, even with costly equipment.

Good airflow design should make sure cold, dry air spreads evenly over the planting area. It should also let return air bring as much moisture as it can back to the dehumidification core for a better SHF.

Environmental Conditions

The weather you see outside shapes what you wear. In the same way, the outdoor environment can quietly influence your indoor SHF. It doesn't stop the conversation like wall insulation. Instead, it keeps your indoor heat and humidity in balance. It does this by using fresh air, air intake vents, heat exchangers, and more.

Outdoor Temperature and Humidity

If your system has a fresh air or make-up air feature, outside air is the "invisible variable."

In summer, hot and dry air brings high sensible heat. The system needs to cool down first, which makes the SHF rise. In the rainy season, humid air carries a lot of latent heat. The system must dehumidify a lot, so the SHF decreases.

The grow room isn't just "an internal system in charge." It's "a complex ecology interacting with the external climate." The SHF changes constantly in this interaction.

Seasonal Variations in Grow Rooms

Remember, the planting room changes with each season. Spring, summer, fall, and winter all have different "temperaments."

Spring and fall can be chilly. Mornings and evenings feel different. The system often switches modes because of SHF changes. In summer, equipment runs non-stop, and high humidity leads to condensation. Winter brings dry and cold air, making it hard to dehumidify as the new air carries a lot of sensible heat.

Smart marijuana growers adjust their operation logic based on the season. This way, they keep the SHF in the "just right" zone.

Type of HVAC System Used

In the end, you’ll see that your efforts mean nothing if you pick the wrong equipment. The way the equipment is built affects how it deals with sensible and latent heat. This heat is the main source of SHF.

Regular home air conditioners usually have high SHFs. They cool well but struggle with dehumidification. This makes them tough for grow rooms.

Industrial comfort air conditioners are moderate. They assume people are the main load and overlook plant transpiration.

A dehumidification system made for plants focuses on latent heat. Even if the SHF isn’t ideal, it leads to more stable results.

Bottom line: Higher SHF is not better, but rather the right fit for your plants and your growing rhythm.

How to Control SHF for a Better Grow Environment

The sensible heat ratio (SHF) is the unsung hero of growing marijuana. It helps balance indoor temperature and humidity. This balance lets your plants thrive and reach their full potential. So, how can you manage your SHF for a better growing space? Here are some key steps to get you started.

Understand Your Room’s Heat Load Composition

Before controlling your SHF, you must know how much "heat" is in your grow room. The concept of heat load may sound abstract, but it's really quite simple: it's the sum of all the factors that affect the temperature and humidity of your environment.Light, equipment, humidity, plant transpiration ...... are all sources of heat load.

Sensible vs. Latent Sources in Grow Rooms

Sensible heat comes from things that warm you directly. This includes lights, fans, and electronic devices. These heat sources mainly control the air temperature.

Latent heat sources don't change temperature as much as sensible heat sources. Instead, they add moisture to the air. This occurs through evaporation. Plants also release water through transpiration. This happens when water evaporates from the soil.

Lighting, Plants, and Moisture as Load Factors

The main sources of heat in marijuana grow rooms are lighting, plants, and humidity.

|

Load Factor |

Descriptive |

Affect |

|---|---|---|

|

Illumination |

Plants need light to grow, especially from high-powered HPS or LED lights. These lights give off heat and help regulate temperature. When choosing lighting, it's important to balance energy efficiency with temperature control. |

It influences room temperature. Proper control of the sensible heat ratio is needed to prevent excessive heat. |

|

Plant Transpiration |

Plants release water through their stomata. This raises air humidity and helps control it. It also increases latent heat load. Healthy plants transpire a lot, which leads to higher humidity. |

Increases latent heat load. It affects humidity control. It needs a balance between humidity and temperature. |

|

Humidity Level |

Humidity in the air impacts its heat capacity. Managing humidity is key for regulating the SHF. Too much or too little humidity can disrupt the sensible heat ratio. |

Affects air heat capacity and an imbalance in humidity control may result in an unstable SHF. |

Rationalizing these load factors lets you adjust the SHF. This way, both temperature and humidity can reach ideal conditions.

Balance Airflow and Dehumidification Effectively

Balancing airflow and dehumidification is key to a perfect grow room. Think of your grow room as a big climate control system. Airflow is like the bloodstream. Good airflow spreads temperature and humidity evenly. This stops overheating and moisture buildup.

How Air Movement Affects Heat and Moisture Distribution

Air movement does more than create a breeze. It impacts temperature and humidity in your grow room. Without good airflow, some areas can get too hot while others become too humid. A well-designed airflow system helps circulate air, balancing heat and moisture. This way, temperatures and humidity stay in check.

Using Variable Speed Fans to Shift SHF

Variable speed fans can help you adjust the SHF in your grow room. They change air speed based on temperature and humidity. This helps you manage airflow and the sensible heat ratio. So, you can easily modify the indoor environment to meet your needs.

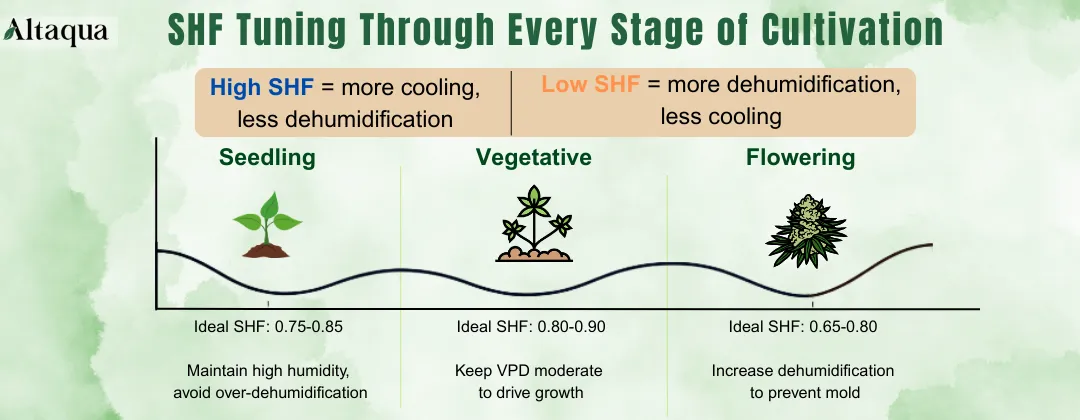

SHF Tuning for Different Growth Stages

During growth, plants have varying environmental needs. Adjusting the sensible heat factor (SHF) is crucial for precise climate control. The SHF shows the ratio of cooling, or sensible heat, to dehumidification, or latent heat. A high SHF means better cooling and less dehumidification. A low SHF means more dehumidification.

Vegetative vs Flowering: Different SHF Needs

During the nutrient phase, the plant grows leaves and stems. Transpiration starts to rise, but it stays moderate overall. To boost growth, lighting systems often run at high power, creating a lot of heat. At this stage, a higher SHF is needed. This means more cooling and less dehumidification. It helps keep the environment moist. It also supports the roots and nutrient tissues.

When the plant reaches the flowering stage, its transpiration rate rises. It releases a lot of water into the air through its leaves, which cools the environment. This means you must manage both the heat from the lights and the moisture from the plants. At this stage, the system needs a lower SHF. This needs better dehumidification. It will lower humidity and help stop mold or disease on the flowers.

Climate Strategy for Maximum Yield

Maximizing yield isn't just about adding more light and nutrients. It’s the combined efficiency of the entire environmental control system that sets the production limit. To grow flowers that are dense, colorful, and flavorful, you need to manage SHF and VPD (Vapor Pressure Difference) carefully at each stage.

At the seedling stage, plants are still young and don’t transpire much. The lighting creates a lot of heat. At this time, you want a high SHF. This means more cooling and less dehumidification to keep temperatures steady.

When plants grow and bloom, they lose water fast, raising humidity levels. If you keep a high SHF now, it can cause too much humidity, harming your flowers. So, you need to lower the SHF to improve dehumidification and keep humidity in check.

How Altaqua HVAC Control Sensible Heat Factor in Grow Room

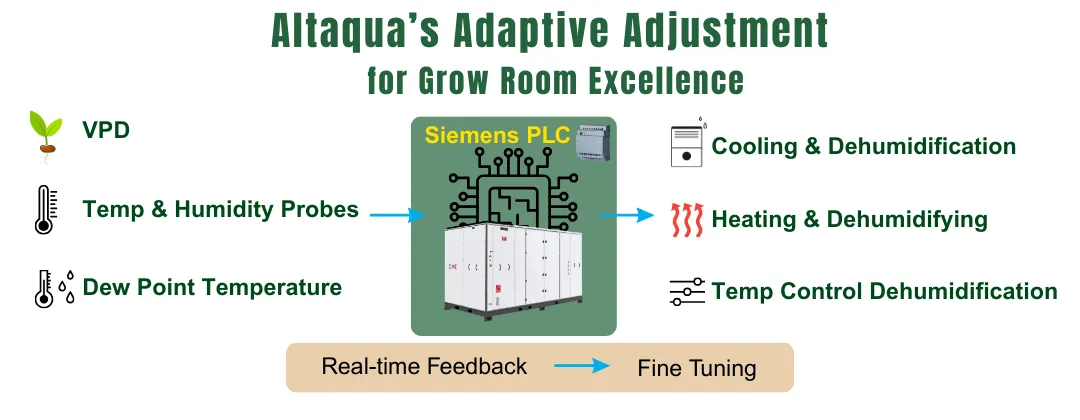

A good air handling system shouldn’t have a fixed output. It needs to adjust the SHF automatically. This means it can switch between cooling and dehumidification based on the plant's needs and environmental load.

Key elements include variable-speed fans, sensitive sensors, and precise control logic. These parts help the system keep pace with plant growth.

Altaqua Grow Room HVAC systems manage changing loads in growing spaces. We offer not just cooling but also smarter heat and humidity control. This helps regulate sensible heat ratios at various growth stages and loads. As a result, your growing area stays in the best condition.

Integrated Temperature and Humidity Control for Balanced SHR

Traditional HVAC systems usually keep temperature control and humidity management apart. In plant growing, this separation can lead to energy waste and environmental changes.

The Altaqua Grow Room HVAC system links temperature and humidity controls to gather real-time indoor data. It uses temperature and humidity sensors, along with dew point monitors. When cooling is needed, it focuses on cooling and dehumidifying. If humidity goes up, it shifts to dehumidification and temperature control. This approach effectively lowers humidity instead of just using cooling to remove moisture.

This fine-tuning ability makes SHF a dynamic factor. It changes based on actual demand. This helps meet plants' environmental needs at each stage.

Airflow and Mode Control for Dynamic Load Response

In a grow room, heat and humidity change all the time. Factors like plant transpiration, light, and people can affect temperature and humidity. The Altaqua Grow Room HVAC system doesn’t depend on human judgment. Instead, it uses a sensor network and smart control logic. This setup senses environmental changes in real time and automatically switches modes.

The EBM high-efficiency EC fan in the system adjusts air speed and volume based on the load. This ensures even airflow coverage and meets both sensible and latent heat needs. For instance, if it senses higher indoor humidity and more evapotranspiration, the system switches to "dehumidification + temperature adjustment" mode. This raises the latent heat ratio. It helps remove water vapor without cooling the plants too much.

Altaqua Grow Room HVAC's control strategy offers more flexibility and precision than traditional HVAC systems. Those systems can only follow setpoints and operate passively.

Dew Point and VPD-Based Intelligent Control Logic

Dew point temperature and VPD are key factors in a growing space. They matter more than just temperature and humidity. The Altaqua Grow Room HVAC System uses smart algorithms. It calculates dew point values and sets target VPD ranges. It does this in real time and adjusts its operating strategy dynamically.

If the dew point goes up, the system will switch to dehumidification mode. If the VPD is off, the system will change temperature and humidity to improve the environment.

Using these smart strategies, the Altaqua Grow Room HVAC System quietly adjusts heat ratios. Plants thrive in the best growth environment, and the grower often doesn't notice this.

Conclusion

Many cannabis growers face problems like humidity, plant stress, or poor yield. These issues often share one common cause: a misunderstood Sensible Heat Factor. SHF isn’t just a number on a spec sheet. It shows the careful balance between cooling the air and getting rid of moisture. This balance can greatly affect your grow room's performance.

We’ve looked at how various factors can change the heat load in your grow room. These factors include lighting systems, room design, and outdoor climate. Most importantly, SHF changes as your plants grow. A veg room needs a different heat-moisture balance than a flowering room. To protect your crop and boost your harvest, learn to read these shifts and adjust your system.

Altaqua Grow Room HVAC solutions are built with growers in mind. They don’t rely on fixed settings or one-size-fits-all assumptions. They use real-time data, dynamic airflow control, and smart mode switching. This helps keep the right SHF at every stage of your grow. The system adjusts to high humidity from growing plants or dry air from strong lights. This keeps your environment balanced, your plants healthy, and your results impressive.

FAQ

1. What is a good sensible heat factor for grow rooms?

SHF for grow rooms is usually 0.5 to 0.8. Lower SHF (0.5) is best during flowering when plants release more water vapor. Higher SHF (0.8) is better during vegetative stage when humidity is easier to control. Adjust SHF dynamically throughout the grow cycle.

2. How does sensible heat factor affect cannabis yield?

The sensible heat factor affects the balance of temperature and humidity. This, in turn, influences the Vapor Pressure Deficit (VPD). VPD is crucial for plant growth and nutrient uptake. If SHF is too high, excess humidity can lead to mold risks. If it's too low, plants may be overstressed. A well-managed SHF keeps VPD ideal, improving plant health, yield quality, and consistency.

3. Why does my HVAC cool the room but not remove enough humidity?

Standard air conditioners focus on comfort cooling, not controlling humidity. If you don't manage both heat and moisture, your space may feel cool but damp. Altaqua's systems can switch to boost dehumidification when needed.

4. How can I lower the sensible heat factor in my grow room?

Lower SHF by improving moisture removal. Use variable speed fans to adjust airflow. Run dehumidification modes during peak transpiration times. Optimize equipment placement to prevent hot spots.

Share with your friends:

Popular Blogs on Altaqua:

Download Catalogue