High-EER HVAC Helps Reduce Costs and Increase Efficiency in Commercial Cannabis Cultivation

Updated: April 21 ,2025 · 15 min read

In commercial cannabis growing, growers face a tough problem. LED lights give off heat, while dehumidifiers and air conditioners run all the time. This causes electric meters to spike. Cannabis growers must maintain quality, but they also can't pay high energy bills.

Every wasted kilowatt-hour cuts into profits. The solution lies in EER (Energy Efficiency Ratio). This simple concept balances temperature, humidity, and energy use in cannabis cultivation.

Many cannabis cultivation facilities are now focusing on the EER of their HVAC systems. EER isn't just a technical term; it measures how energy use translates into real benefits. In this article, we’ll explore EER. Once you grasp its importance, you’ll see how energy costs can become a clear competitive edge.

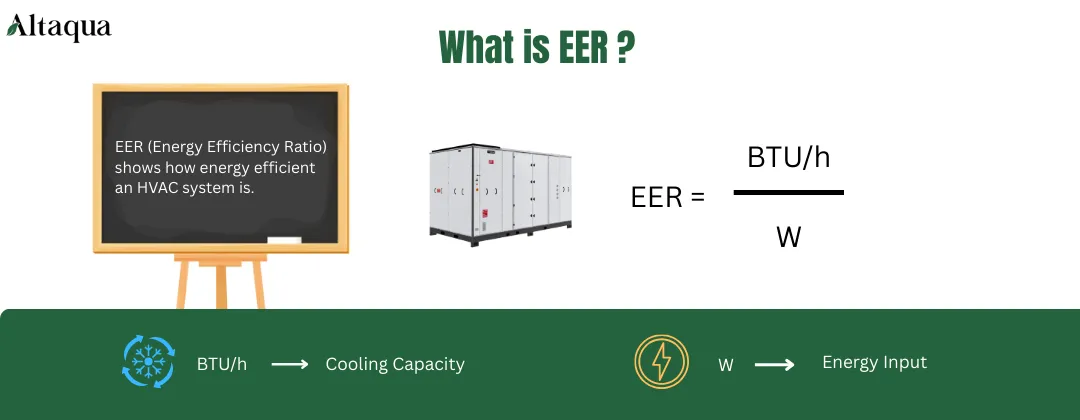

What is EER?

The EER, or Energy Efficiency Ratio, shows how efficient an HVAC system is. It compares the cooling a unit offers to the electricity it uses.

A higher EER means the system gives more cooling for the same energy use. It also works more efficiently.

In other words, a high EER in your HVAC system means it can "do more with less." On hot days or humid nights, a high EER keeps your plants safe and healthy.

Defining Energy Efficiency Ratio for HVAC System

From a technical point of view, the formula for calculating EER is:

EER = Cooling Capacity (BTU/h) ÷ Power Consumption (W)

As a simple example, if an HVAC system is capable of delivering 12,000 BTU/h in cooling mode while consuming 1,200 watts of electricity, its EER would be 10. This means that for every watt of electricity consumed, it can deliver 10 units of cooling.

In a commercial setting, like a high-energy cannabis grow facility, this calculation helps you decide if the system is worth using.

Why EER Matters More in Cannabis Cultivation

In a cannabis grow room, the HVAC system runs nearly all the time. High-intensity LED lights create constant heat. Also, high humidity can lead to mold. Temperature and humidity changes during plant growth add more stress. All these factors put a heavy demand on the HVAC system.

A low EER HVAC unit costs more to run. It raises your electricity bills for the ideal cannabis growing environment. In contrast, a high EER system cuts energy use. It also reduces compressor strain and helps your equipment last longer. This way, your cannabis grow room operates more efficiently and steadily.

Also, profit margins for cannabis cultivation are tightening. So, cutting operating costs is crucial for staying ahead of the competition. EER is a key technical measure that impacts the cost structure for cannabis growers.

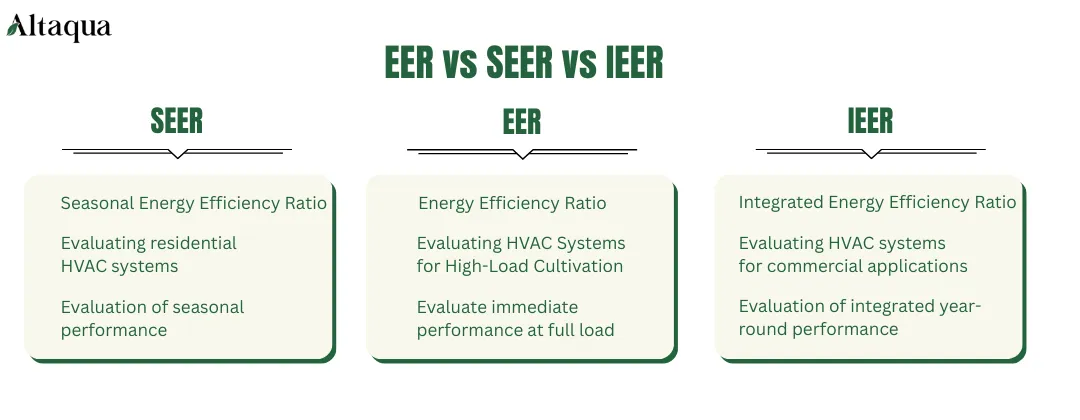

EER vs SEER vs IEER

Cannabis growers researching HVAC equipment will often find EER, SEER, and IEER. These terms all relate to energy efficiency, but they serve different purposes.

SEER: Seasonal Efficiency for Residential vs Commercial Needs

SEER (Seasonal Energy Efficiency Ratio) shows how well a residential HVAC system uses energy in the cooling season.

It considers factors like temperature changes and how often the unit turns on and off. This makes it better for evaluating a home air conditioner's yearly performance. However, in commercial grow rooms that run all day and night, SEER is less useful. It doesn’t show how the system performs under tough conditions, like high heat or humidity.

IEER: Why Integrated Ratings Fit High-Demand Cannabis Facilities

IEER (Integrated Energy Efficiency Ratio) combines energy efficiency ratios. It works better than SEER for commercial uses, especially where load varies a lot.

The IEER helps estimate how efficiently a system works at various partial loads, but it's just an average. For growing cannabis, the IEER shows system efficiency under different loads, but it's just an average. EER stands out because regular air conditioners only handle daytime peaks. In contrast, HVAC systems in grow rooms face constant challenges. These include heat from LED lights, extra load from dehumidifiers, and varying CO₂ levels, all day long.

In contrast, the EER measures the system's performance at full load. This makes EER a better choice for assessing equipment performance during peak demand when power use is highest.

Breaking Down the EER Calculation Formula

The formula for calculating EER is:

EER = Cooling capacity (BTU/h) ÷ Power consumption (W)

To calculate the EER, you need two key numbers: cooling capacity and power consumption. Cooling capacity is in BTU/h, while power consumption is in watts. You can usually find both of these figures in the equipment's technical data sheet.

|

Parameter Name |

Meaning |

|---|---|

|

Cooling Output |

Indicates the amount of heat an HVAC system can remove in one hour, expressed in BTU/h |

|

Power Input |

Indicates the amount of power consumed by the unit during operation, in watts (W) |

When you divide the cooling capacity by the power consumption, the resulting value is the EER.

How to Measure EER in a Grow Room

In an actual grow room environment, measuring EER can be accomplished in the following steps:

1. Confirm that the equipment is operating at full refrigeration capacity. This is needed to calculate EER.

2. read the cooling output (BTU/h), which can usually be obtained from the equipment datasheet or the system monitoring platform.

3. record the current power consumption (W), you can use a power monitor or smart meter to measure the actual power of the HVAC system.

4. Divide the two values to get the real-time EER value.

If your HVAC system links to a central control platform or remote monitor, it might show EER values in real-time. This helps you track energy efficiency changes and make quick adjustments for better performance.

How High-EER HVAC Stabilizes Cannabis Grow Environment

During cannabis cultivation, the environment's stability impacts plant health and yield. High EER (Energy Efficiency Ratio) HVAC systems help create ideal conditions. They control temperature, humidity, and airflow precisely, even in challenging settings.

A high EER saves on energy costs and boosts productivity. It also ensures a steady growing environment.

Precision Temperature Management

Temperature is key for growing cannabis. Even small changes can harm or kill plants. High EER HVAC systems help keep the temperature just right, so plants grow healthy.

Preventing Heat Stress in High-Intensity LED Setups

In cannabis cultivation, growers often use high-intensity LED lights to boost plant growth. These lights save energy compared to traditional options. Still, they produce a lot of heat when used for long periods. This heat can make it tough to control the temperature in grow rooms. If it gets too hot, plants can suffer from heat stress. This can stunt their growth and reduce active ingredients.

Our high EER Altaqua Grow Room HVAC System with dew point control addresses this issue. Traditional HVAC systems focus on dry bulb temperature. However, in a growing environment, temperature and humidity affect each other. Dew point control directly manages the water vapor in the air. This makes it easier to control the relationship between temperature and humidity. It helps stabilize leaf temperatures and VPD (Vapor Pressure Difference). This is key to preventing heat stress.

Even a 2°C temperature fluctuation may result in a 15% reduction in resin production during the flowering phase of cannabis. Our Altaqua Grow Room HVAC System features humidity and temperature sensors from E+E, an Austrian brand. These sensors are highly accurate. They help create a stable environment in a 'golden microclimate zone.' The system keeps fluctuations to ±2.5% RH and ±0.54°F. This setup buffers outside changes and lowers the risk of heat stress on cannabis.

The High EER HVAC system controls heat and protects plant health. It also keeps a stable, efficient growing environment for cannabis. Plus, it avoids raising energy use. This leads to higher yields and better quality crops for growers.

Maintaining Night Cycle Temperatures Without Overshooting

Controlling light during the day is key. But managing nighttime temperatures is just as important for cannabis growth. Many growers overlook how nighttime temperatures impact plant metabolism. If it gets too cold at night, cannabis plants can struggle. It can slow breathing, disrupt cell functions, and change nutrient flow during flowering. As a result, yield and quality may drop.

High EER HVAC systems provide great temperature control. They adjust automatically to load changes at night. This keeps a precise temperature range. It also prevents big swings in temperature caused by cooling down or warming up too fast.

If our Altaqua Grow Room HVAC System senses a steady drop in temperature after dark, it will switch to temperature control and dehumidification mode. Then, it will analyze the humidity level and decide how much to adjust the temperature. This helps manage the nighttime environment more smoothly and accurately. It stops cold stress from low temperatures. It also provides a safe space for plants to recover and grow at night.

Precision Humidity Management

Humidity greatly affects cannabis plant growth, especially in the flowering stage. Proper humidity helps plants grow healthy and prevents diseases like mold.

Stopping Mold with Sub-3% RH Fluctuation Technology

Mold often troubles cannabis growers, especially in humid conditions. It harms plant quality and can cause big financial losses. High EER HVAC systems fight mold by keeping humidity changes within 3%. This control creates stable growing conditions. It helps keep plants healthy and safe from pests and diseases.

Our system uses smart dew point control to check and adjust humidity levels instantly. Dew point control is better than traditional methods. It shows how much water vapor is in the air, instead of separating temperature and humidity. This helps reduce fluctuations caused by humidity or too much dehumidification. Plus, the Austrian E+E sensor in our system keeps relative humidity changes within ±2.5%RH.

This humidity control keeps a stable environment even in high humidity. It creates perfect conditions for cannabis growth. Plus, it lowers the chances of pests and diseases, protecting the health and quality of the plants.

Maintain Appropriate VPD (Vapor Pressure Difference)

Vapor Pressure Difference (VPD) is crucial for plant water uptake and transpiration. High EER HVAC systems adjust automatically to temperature and humidity. This keeps VPD in the proper range for plant growth. When VPD is right, plants absorb water and nutrients more effectively. This promotes growth and boosts crop quality and yield.

Our Altaqua Grow Room HVAC System s use Siemens PLC control panels. They offer an easy-to-use interface. Growers can set target temperature and humidity levels right from the panel. They can also monitor real-time VPD values to keep ideal growing conditions!

The High EER system helps cannabis growers keep a steady VPD. This works well even when the environment changes. As a result, plants can grow better and produce more.

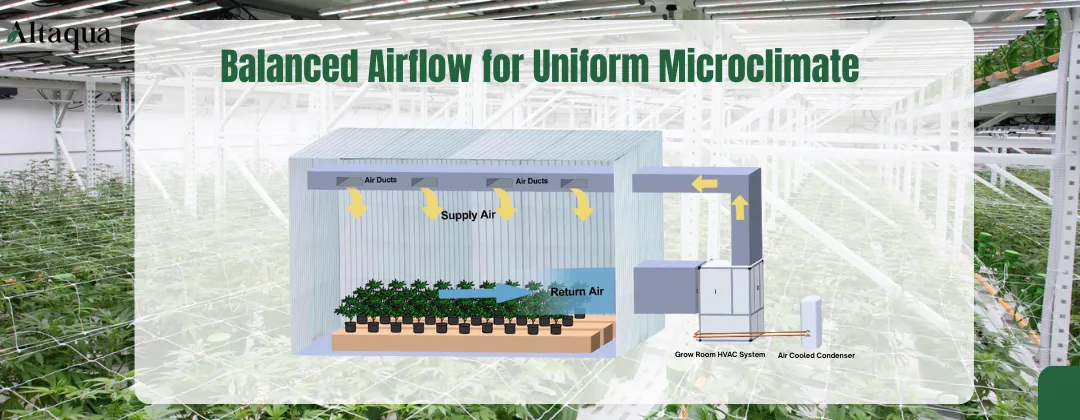

Optimizing Airflow Management

Stable airflow is key for a healthy growing environment. High EER HVAC systems keep a steady microclimate in the grow room. They do this by optimizing airflow.

Ensuring Uniform Air Distribution for Stable Microclimates

Uneven airflow during cannabis cultivation can cause hot or humid spots. This harms plant health and leads to uneven growth, affecting both yield and quality.

In tight growing spaces, heat and moisture levels can differ a lot. If not managed quickly, these issues can cause problems. Plants may suffer from heat stress and mold, which harms crop quality.

A high EER system provides even airflow in every corner of the grow room. It controls air speed and direction. This helps avoid big differences in temperature and humidity.

Our Altaqua grow room HVAC System uses a smart ducted airflow design. It sends air to every corner of the grow space. This system is better than traditional designs because it spreads air more evenly. It cuts down on hot and cold spots, keeping temperature and humidity balanced. This setup prevents temperature and humidity from becoming too high in one area. It also creates a stable environment, allowing each cannabis plant to thrive in ideal conditions.

Optimizing airflow helps cannabis growers create a balanced environment for every part of the plant. This boosts both yield and quality.

Integrating CO₂ and HVAC System for Maximum Efficiency

CO₂ helps plants grow through photosynthesis. More CO₂ can boost their growth. But too much or uneven CO₂ can create issues. High EER HVAC systems control temperature and humidity. They also connect to the CO₂ supply system. This ensures even gas distribution and reduces waste.

Our systems use smart fresh air exhaust control. They automatically turn the CO₂ generator on or off based on CO₂ levels. If the CO₂ concentration drops below 400 PPM, the generator turns on. It stops when the target level is reached. If CO₂ exceeds 1,000 PPM, the system activates fresh air and exhaust functions to keep the environment optimal.

Optimizing CO₂ use boosts energy efficiency. This helps plants grow in the best environment for maximum benefits.

How High EER HVACs Reduce Energy Costs

In the cannabis cultivation industry, energy efficiency cuts costs and boosts sustainability. High EER (Energy Efficiency Ratio) HVAC systems are key. They use energy wisely and minimize waste while keeping a stable growing environment. By using these systems, growers lower energy use and enhance crop quality and yield. It’s a win-win!

Optimizing Power Usage with High-EER HVAC

In a busy commercial growing space, it's important to optimize energy use to cut costs. High EER HVAC systems help by maximizing energy efficiency and reducing wasted power.

Reducing Energy Waste by Maintaining Optimal Performance

High EER HVAC systems are designed to always maintain optimal system operation through intelligent controls and high efficiency.When the equipment is at peak performance, it provides the desired temperature and humidity regulation with minimal energy consumption.

Our Altaqua Grow Room HVAC System s combine cooling, heating, and dehumidification in one unit. This means you get air conditioning and humidity control without needing separate units. Stand-alone machines only manage humidity, which can be tricky for large greenhouses. In those spaces, many machines are needed, making it hard to control every corner effectively.

Dehumidifiers produce a lot of heat when they run. If the greenhouse needs cooling, this adds extra strain. A bigger air conditioning system is needed to balance the heat from the dehumidifier. Having separate cooling and dehumidification systems can be tough and inefficient. This can result in poor performance and higher costs for the grower.

Our Altaqua Grow Room HVAC System s can automatically switch between dehumidification and cooling or heating. It does this based on the humidity and temperature settings. Dehumidifiers and air conditioners work well together in controlling temperature. The initial cost might be a bit higher, but they save energy over time.

Smart Load Adjustment for Efficient Power Consumption

High EER's HVAC system adjusts power output based on the grow room's needs. If the outside temperature changes or the inside humidity needs adjustment, the system figures out the energy needed and makes changes. This allows the system to match energy use to real-time demand. It avoids the over- or under-distribution of energy seen in typical systems. As a result, it greatly boosts overall energy efficiency.

Our Altaqua Grow Room HVAC System has EBM EC fans. These fans adjust air speed based on the temperature. This keeps airflow balanced and efficient, saving energy. They last longer and work better than regular fans. Plus, they cut down on power use at low loads, which lowers energy costs.

This smart adjustment system helps the HVAC work well under various loads. It monitors in real-time and provides feedback. This way, it saves energy and keeps a stable, reliable indoor environment.

Lowering Operating Costs Through Advanced System Design

High EER HVAC systems save energy and cut costs. They use smart design to keep equipment running well for a long time. This design helps lower maintenance needs and reduces breakdowns.

High-Efficiency Compressors Minimizing Energy Consumption

Compressors play a key role in HVAC systems. Their efficiency directly affects energy use. High EER HVAC systems use high-efficiency compressors, which lower energy consumption significantly.

Altaqua Grow Room HVAC Systems have built-in redundancy. This feature ensures they operate continuously and reliably. Altaqua HVAC for grow rooms uses multiple compressors and control circuits. This keeps performance steady, even if one part fails. This design reduces the risk of unexpected downtime. It helps growers protect their crops. It also keeps climate conditions ideal without interruptions.

Optimizing the compressor improves its efficiency. This reduces energy losses. As a result, the system offers accurate temperature and humidity control. It also cuts power usage and lowers operating costs.

Enhanced Airflow Management for Improved Heat Exchange

Airflow management is vital for better HVAC efficiency. High EER HVAC systems enhance heat exchange by optimizing airflow paths and speeds. With the right airflow speed and direction, the system removes heat from the air more effectively, cutting energy use.

Our systems have a smart heat recovery design. It captures waste heat from cooling. Then, it uses that heat to warm the dehumidified air. Finally, this heated air goes back to the grow room. This process stops overcooling. It stabilizes the environment and cuts down on extra heating needs. Consistent temperature and humidity in grow rooms make air conditioning more efficient. This also creates the best conditions for plants to thrive.

This precise airflow management boosts equipment performance. It also makes the whole HVAC system more energy efficient.

Intelligent Energy Management Reduces Electricity Bills

The High EER HVAC system allows for smart energy control, which cuts electricity bills. It monitors temperature and humidity in real time. Then, it adjusts operations to use energy only when needed, avoiding waste. Whether it's hot, humid, or low load, the system changes power output based on demand. This way, every bit of energy gets used effectively.

The system has efficient EC fans that adjust wind speed based on the temperature. This helps cut down on power use. It also uses heat recovery and smart load control. This helps reduce energy use while keeping temperature and humidity steady. This smart management helps growers use less power at peak times. It also balances their load, which cuts down electricity costs.

Smart energy management helps growers save energy and cut waste. It also optimizes equipment use for long-term savings. This flexible approach makes the High EER HVAC system ideal for cannabis cultivation. It helps save energy and boost efficiency at the same time.

Conclusion

As cannabis cultivation grows, controlling the environment is key. Choosing the right HVAC system is essential. High EER (Energy Efficiency Ratio) systems help growers save energy by cutting waste. They keep temperatures and humidity steady in the grow room. With smart temperature control, load regulation, and efficient compressors and fans, growers can boost crop quality and yields. Plus, they can lower operating costs significantly.

These systems have smart management features that ensure even air distribution. This helps prevent big temperature and humidity swings, making the growing environment better. Their advanced control of temperature, humidity, and dew point reduces mold risk. This helps keep crops healthy. Also, the system connects well with the CO₂ supply, enhancing gas distribution. This boosts energy efficiency and promotes crop growth in the grow room.

Choosing a high-EER HVAC system cuts energy use and helps create a healthy space for growing cannabis. This investment pays off over time. It helps growers save on electricity. At the same time, it boosts crop quality and supports a sustainable, efficient setup.

FAQ

1. What is EER and why is it important for HVAC systems?

EER (energy efficiency ratio) shows how efficient an HVAC system is. It compares the cooling capacity to the power it uses. The higher the EER value, the more energy-efficient the system. High EER HVAC systems in hemp cultivation help growers save energy. They lower power use and operating costs. At the same time, they keep the growing environment stable. It is essential for modern greenhouse systems. It cuts energy waste by controlling temperature and humidity precisely. This boosts overall energy efficiency.

2. How can cultivation costs be reduced with a high EER HVAC system?

With a high EER HVAC system, growers can significantly reduce energy consumption. A high EER value means the system uses less energy. This helps meet the needed temperature and humidity while cutting electricity costs. High EER systems are smarter than traditional ones. They adjust power output based on the environment. This helps avoid wasting energy. The system also uses efficient fans and compressors. This optimizes airflow and heat exchange, which cuts energy costs. Growers can enjoy significant long-term savings.

3. How does a high EER HVAC system maintain a stable growing environment?

High EER HVAC systems keep grow rooms comfortable. They control temperature and humidity smartly. Also, they manage airflow precisely to ensure consistent conditions everywhere. The system can automatically change the temperature, humidity, and CO₂ levels. This helps create the perfect environment for growing cannabis plants. The system's smart load adjustment feature helps equipment use energy only when it's needed. This helps prevent energy waste. Optimizing air distribution, temperature, and humidity helps growers create stable conditions. This, in turn, boosts crop health and yield.

4. How does the high EER HVAC system reduce mould growth in cannabis cultivation?

Mould often appears in cannabis growing, especially in humid places. High EER HVAC systems help stop mould growth. They do this by keeping humidity changes within 3%. The system uses dew point control technology. It adjusts humidity in real time. This helps prevent too much wetness or dryness, which is key for mold control. By controlling humidity and airflow, growers can lower pests and diseases. This also creates a perfect environment for plants, boosting both crop quality and quantity.

Share with your friends:

Popular Blogs on Altaqua:

Download Catalogue