Why Reheat Determines Whether a Grow Room HVAC Actually Works

Updated: Dec. 25 ,2025 · 6 min read

Abstract: Many grow rooms experience recurring humidity issues even when HVAC systems are operating. In most cases, the problem is not tuning or equipment capacity but system design. Without proper grow room hvac reheat, dehumidification is limited by temperature control, causing systems to shut down early and humidity to rebound—especially at night. Grow room hvac reheat allows continuous dehumidification while maintaining stable temperature, making it a system-level requirement rather than an optional feature in commercial grow room HVAC design.

If you’ve ever tried to manage humidity in a grow room, this situation probably sounds familiar. You start dehumidification, relative humidity begins to drop, and everything looks fine at first. Then room temperature falls faster than expected, the system shuts off, and a few hours later—often during lights-off—humidity climbs right back up.

When this happens, most growers assume the problem lies in the settings, the sensors, or daily operation. In reality, the issue is rarely operational. It is structural. In many cases, the real limitation comes down to one overlooked part of HVAC design: reheat.

Not whether reheat is mentioned on a datasheet, but whether the system is actually designed to use reheat correctly under grow room conditions. That distinction is what separates a system that looks capable on paper from a grow room HVAC reheat design that actually performs in real cultivation environments.

What Reheat Means in a Grow Room HVAC System

Before diving into different reheat options or breaking down why some systems struggle, it helps to pause and get one thing straight: what reheat actually does in a grow room HVAC system. It’s often misunderstood as just another form of heating, but that’s not really the case. Reheat plays a very specific role, and it’s closely tied to how dehumidification actually works. A lot of humidity control problems come from missing this connection—or oversimplifying what reheat is meant to do in the first place.

Why Reheat Is Not Just “Heating the Air”

Reheat is often misunderstood as a simple heating function. In grow room HVAC systems, it has nothing to do with comfort and very little to do with raising room temperature. Its purpose is much more specific.

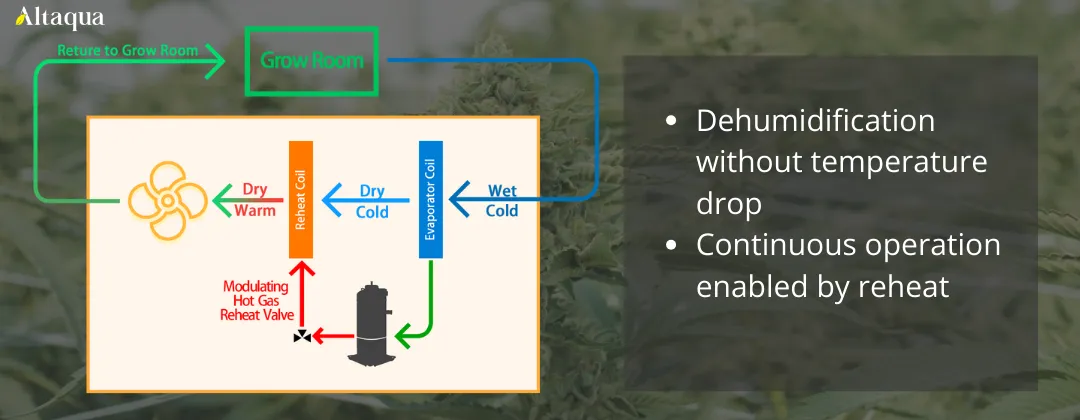

To remove moisture from the air, the HVAC system must cool air below its dew point. That cooling process removes latent heat, but it also strips away sensible heat. Without a way to manage that sensible heat loss, temperature quickly becomes the limiting factor that shuts the system down.

Reheat exists to restore balance during dehumidification. It allows the system to remove moisture while preventing temperature from dropping out of range. In other words, reheat is what allows dehumidification to continue instead of stopping prematurely.

Why Reheat Is Critical for Humidity Control

Once reheat is understood as a control mechanism rather than a comfort feature, its importance to humidity control becomes much clearer. Effective humidity control in grow room environments depends less on setpoints and more on whether the HVAC system can stay online long enough to deal with continuous moisture generation.

Without reheat, dehumidification is always interrupted by temperature limits. The system cools, reaches its cutoff, shuts down, and humidity immediately begins to rebound. Reheat removes that bottleneck by decoupling moisture removal from temperature shutdown, which is why it is fundamental—not optional—for stable grow room environments.

What Happens When a Grow Room HVAC Has No Reheat

Understanding what reheat does makes it easier to see what goes wrong when it is missing. In systems without proper reheat, instability is not random. It follows a predictable pattern driven by the same physical constraints repeating themselves over and over.

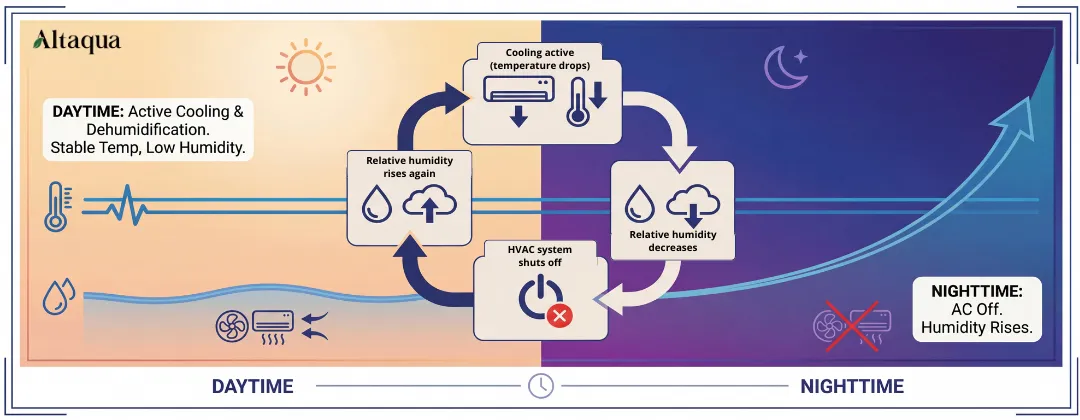

The Classic Dehumidification Failure Loop

When a grow room HVAC system lacks proper reheat, it tends to follow a predictable failure pattern. The system starts cooling to remove moisture, room temperature drops rapidly, and once the temperature setpoint is reached, the system shuts off. Dehumidification stops at that moment, even though moisture generation from plants continues.

As humidity creeps back up, the system kicks on again—only to fall into the same loop. On, off, on, off. That constant cycling creates an unstable environment, with temperature and humidity never quite settling where they should. And the real problem isn’t a lack of cooling power. It’s that the system simply can’t stay running long enough to deal with the latent moisture load properly.

Why Standalone Dehumidifiers Cannot Solve This

Because this failure loop is so common, many facilities try to compensate by adding standalone dehumidifiers. While this approach seems logical on the surface, it does not address the root of the problem.

Standalone dehumidifiers remove moisture independently of the cooling system, without coordinating temperature limits or overall runtime. In a latent load grow room, where plants release moisture continuously, this fragmented approach often increases instability rather than resolving it—especially during lights-off periods.

Hot Gas Reheat vs Electric Reheat: The Real Difference

Once the need for reheat is clear, the next question usually becomes what type of reheat is appropriate. Although both hot gas reheat and electric reheat aim to solve the same problem, they do so in fundamentally different ways, with very different implications for energy use and long-term performance.

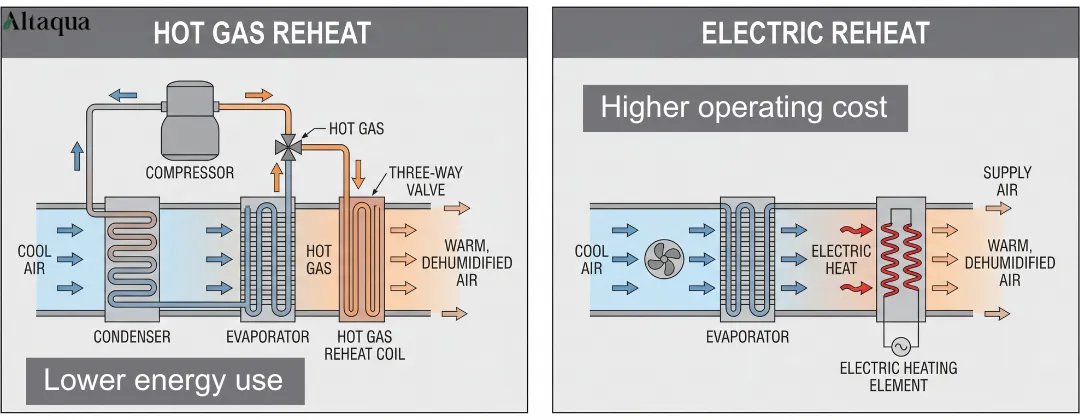

How Hot Gas Reheat Works in Grow Room HVAC

Hot gas reheat uses heat already generated by the refrigeration cycle. Rather than rejecting that heat outdoors, the system redirects a portion of it back into the air stream during dehumidification. This recovered heat offsets sensible cooling without adding additional energy demand.

This design allows for simultaneous cooling and dehumidification, rather than forcing the system to choose between temperature control and moisture removal. The practical result is stable conditions and continuous operation, which is especially important in sealed commercial facilities.

Why Electric Reheat Is a Compromise, Not a Solution

Electric reheat approaches the problem differently by adding heat after cooling has occurred. While this can prevent temperature from dropping too low, it does so by increasing electrical demand.

In a commercial grow room, dehumidification often runs for hours every single day. When electric reheat is part of that setup, operating costs can climb fast. It also tends to respond more slowly, efficiency takes a hit, and scaling the system long term starts to feel risky. Because of that, electric reheat is usually treated as a stopgap—something that works for now, but not a solution most growers want to rely on forever.

Why Reheat Determines Whether a Grow Room HVAC Can Truly Dehumidify

By this point, it becomes clear that reheat affects more than just temperature balance. It directly determines whether a system can operate as an integrated grow room HVAC, where cooling, dehumidification, and control logic function together rather than as isolated processes.

Reheat Enables Continuous Dehumidification

The defining advantage of proper reheat is continuous system operation. When temperature is no longer the limiting factor, the HVAC system can focus on managing latent moisture loads consistently instead of cycling on and off.

This continuity is what allows humidity control to become predictable rather than reactive. It also reduces mechanical stress, minimizes short cycling, and improves overall system reliability.

Reheat Is a System-Level Feature, Not an Add-On

Reheat cannot be evaluated as a standalone component. It is not just a coil or a heater. Its effectiveness depends on refrigerant routing, control logic, and how the system prioritizes latent versus sensible loads.

If reheat is not considered during the initial HVAC design phase, adding it later rarely delivers the same results. True reheat performance comes from systems that are designed around dehumidification from the start.

When Reheat Becomes Non-Negotiable in Commercial Grow Rooms

As grow rooms increase in size and production demands rise, reheat moves from a design preference to a requirement. Certain symptoms consistently signal that a system has reached the limits of what it can achieve without proper reheat integration.

Signs Your Grow Room HVAC Actually Needs True Reheat

If you’re dealing with humidity spiking every night, temperatures bouncing around whenever dehumidification kicks in, or a system that’s constantly cycling on and off—while energy bills keep creeping up—those aren’t simple tuning issues. They’re signs of deeper, built-in limitations. No amount of control tweaks or add-on equipment is going to fully fix that.

At a commercial scale, patterns like these usually mean one thing: the system needs a properly integrated reheat strategy, not another workaround.

Conclusion

In a grow room HVAC system, reheat isn’t some optional add-on or a comfort feature you can take or leave. It’s what determines whether the system can actually pull moisture out of the air without throwing temperature control off balance. In commercial grow rooms—where latent loads never really stop and consistency matters every day—reheat is what allows the HVAC system to do its job the way it’s supposed to.

When a system keeps struggling with humidity even though the capacity looks fine on paper, reheat design is often the missing link. Without it, even a properly sized system will start to fall short once real-world operating conditions set in.

FAQ

Q1: Why is reheat necessary in a grow room HVAC system?

Reheat lets the system keep removing moisture without overcooling the room. That balance is key in grow rooms, where temperature and humidity both need to stay steady—not fight each other.

Q2: What is the difference between hot gas reheat and electric reheat?

Hot gas reheat recycles heat from the refrigeration process itself. Electric reheat, on the other hand, adds extra heat from an external source, which usually means higher energy use and lower efficiency—especially at commercial scale.

Q3: Can a grow room control humidity without reheat?

Not very well. Without proper reheat, dehumidification is limited by temperature setpoints. The system ends up cycling on and off, and humidity becomes unstable, particularly during lights-off periods.

Share with your friends:

Popular Blogs on Altaqua:

Download Catalogue