Commercial Grow Room HVAC Design: The Ultimate Guide to Stopping Nighttime Humidity Spikes, Saving Energy, and Stabilizing Yields

Updated: Dec. 5 ,2025 · 10 min read

Have you ever lived through this nightmare? Everything looks perfect during the day, but 30 minutes after the lights go out, the humidity instantly spikes to over 80%. If you are still relying on a traditional setup of "standard AC + portable dehumidifiers," this outcome is almost inevitable.

Designing a commercial grow room HVAC system is far more difficult than designing for a standard office building. In a sealed, high-humidity grow environment, temperature and humidity loads don't change slowly and smoothly. Instead, they feature instantaneous fluctuations driven by biological loads:

- Light Cycle Switches: When lights go from On to Off, sensible heat crashes instantly, but latent heat (moisture) keeps coming.

- Constant Transpiration: Plants continuously release moisture, accumulating a massive humidity load.

- High-Intensity Lighting: LED and HPS fixtures create huge amounts of sensible heat.

- The "Nightmare" Spike: Once the AC stops cooling at night, humidity skyrockets.

- Microclimates: Localized pockets of heat and moisture mess up your controls.

A grow room’s HVAC system is not a scale up of “Comfort Cooling” but rather is “Process Cooling.” This is not a tweak, it is rewriting the engineering level logic entirely. So there are six dimensions you can master to create a compliant, safe and efficient facility with stability:

- 1. Load Modeling

- 2. Integrated Temperature & Humidity Control (HVACD)

- 3. VPD-Based Control (Vapor Pressure Deficit)

- 4. Multipoint Sensing

- 5. Airflow Engineering

- 6. ROI Calculation (Energy & Cost Efficiency)

This article will break down these six dimensions to help you understand the commercial grow room HVAC design system driven by biological loads.

Why Traditional HVAC Systems Fail in Commercial Grow Rooms

The climate load in a grow room is dominated by biological processes, not just mechanical equipment or the building itself.

The Logic of Traditional HVAC:

"Space sensible heat is the main factor; humidity load is relatively stable."

The Logic of a Grow Room:

"Space latent heat (humidity) is extremely high, and sensible heat fluctuates wildly with the light cycle."

Because these logics are opposites, standard HVAC for grow room applications will almost always fail.

The Bio-Load × Thermal Load Coupling Effect

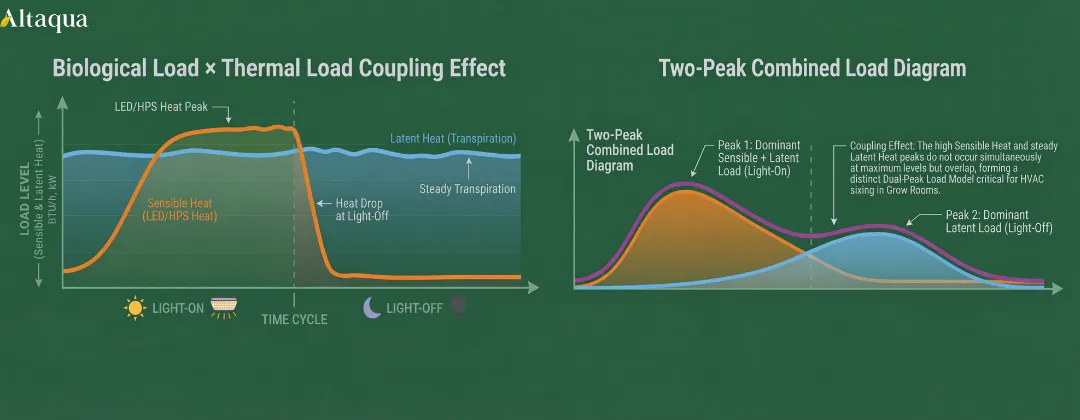

The most unique engineering phenomenon in cannabis hvac design is the Double-Peak Load Model created by plant transpiration and lighting heat:

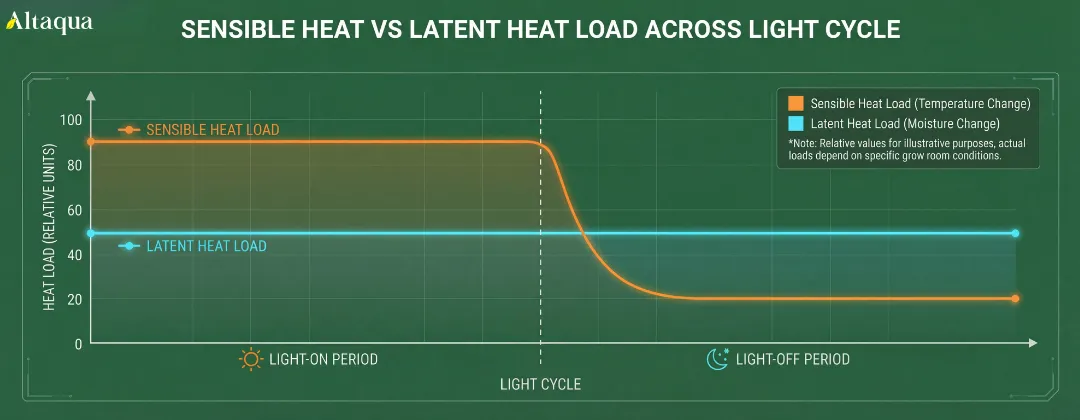

- Sensible Heat: Determined by your LED/HPS lights.

- Latent Heat: Determined by plant transpiration.

Here is the problem: They are asynchronous. When you turn off the lights, the moisture load doesn't stop. This leads to:

- Lights On: High Sensible Heat + High Latent Heat.

- Lights Off: Sensible Heat Crashes + Latent Heat Remains High → Instant Humidity Spike.

This is the core challenge of grow room HVAC.

The "Lights-Off" Shock

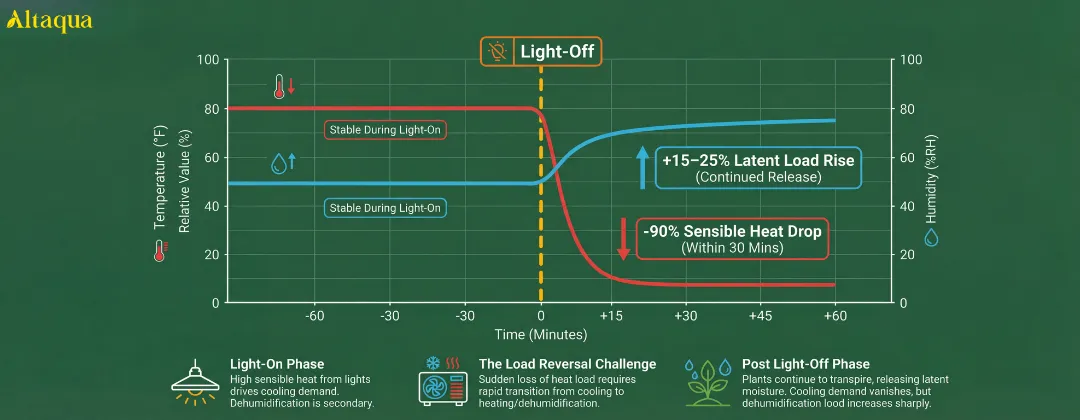

One of the hardest problems to solve in grow room HVAC system design is this: Within 30 minutes of lights out, sensible heat drops by 90%, but latent heat continues at 100%.

This is where most non-specialized HVAC engineers fail.

For example, with 600W LEDs or 1000W HPS lights: About 20–30 minutes after shutoff, the lights still release about 8–10% residual heat. After that, sensible heat hits zero, but transpiration keeps pumping moisture into the air.

The Result: A HVAC Nightmare

|

Time |

Sensible Heat |

Latent Heat |

HVAC Challenge |

|---|---|---|---|

|

Lights On |

High |

High |

System must cool and dehumidify simultaneously. |

|

Just Off |

Medium |

High |

Temps drop, humidity rises, RH spikes. |

|

Deep Night |

Low |

Medium |

AC stops cooling; dehumidification fails. |

This leads to the infamous Nighttime Humidity Spike. This is exactly why an AC system that works perfectly in an office building will cause crop failure when moved into a grow room.

VPD: The "Lifeline" Metric for Grow Rooms

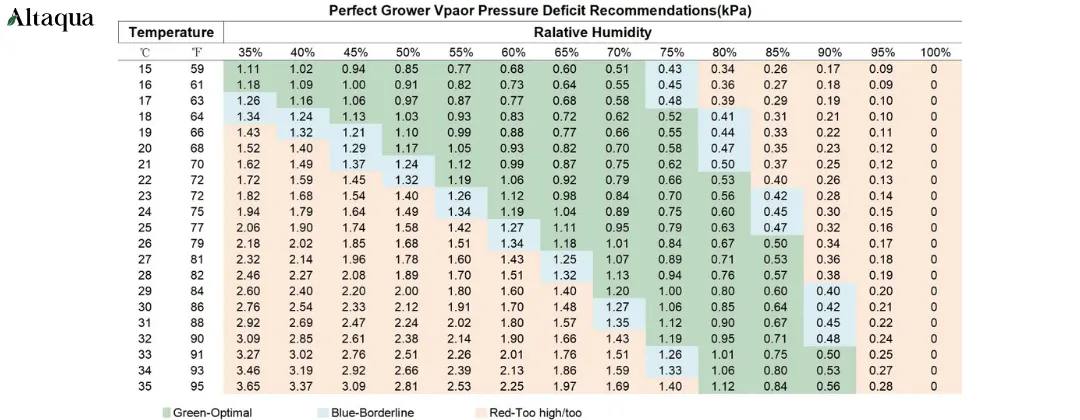

A professional grow room HVAC setup doesn't just chase temperature and humidity readings; it is a climate control system driven by VPD (Vapor Pressure Deficit).

VPD impacts everything:

- Transpiration rates

- Nutrient transport

- Stomatal conductance

- CO₂ absorption efficiency

Industry Standard VPD Ranges:

|

Stage |

VPD (kPa) |

Climate Focus |

|---|---|---|

|

Clone |

0.4–0.8 |

High humidity, low airflow, stable temps. |

|

Veg |

0.8–1.1 |

Balanced temp/humidity, stable CO₂. |

|

Flower |

1.0–1.4 |

High dehumidification, low RH, stable airflow. |

Your commercial grow room HVAC must pursue VPD stability, not just stable numbers on a thermostat.

The Importance of Accurate Load Modeling

There is simply no way to model a grow room with conventional building software, because the room’s latent heat comes from “biological processes.”

Key Takeaways:

At least in a typical grow room, we've found that Latent Load (Moisture) ≈ 1.4 to 2.8 x Sensible Load. This is the opposite of how comfort cooling works, where the ratio between sensible and latent loads (sensible/latent load ratio) is around 0.7-0.8.

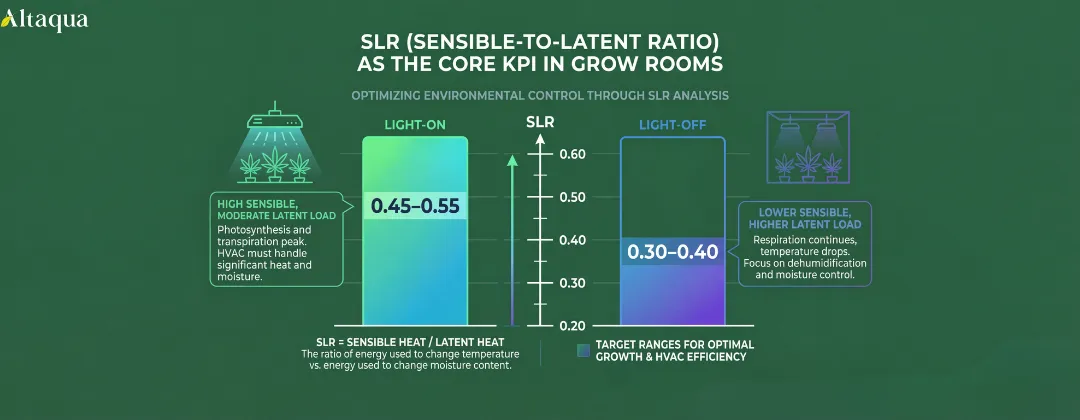

The Real SLR in a Grow Room:

- Lights On: 0.45–0.55

- Lights Off: 0.30–0.40

If you compute this SLR wrongly, then you have:

- Over-cooling by the AC

- Insufficient dehumidification

- AC vs Dehumidifiers battling against each other

- Skyrocketing energy costs

Moisture at Night Needs Its Own Model

At night, the system largely ceases cooling, yet plants continue transpiring moisture. Typically, humidity can climb 15–25% within an hour after lights-out, peaking 2–3 hours later. If temperatures drop too low, standalone dehumidifiers become largely ineffective—their efficiency plummets, creating ideal conditions for mold and powdery mildew growth.

Therefore, nighttime latent heat loads must be modeled separately. Never apply daytime data to nighttime scenarios, or problems are guaranteed.

HVACD Integration: No Other System Matches The Long-Term Stability

The traditional “air conditioner + dehumidifier” combo is actually quite wasteful. The AC works hard to cool the space while the dehumidifier heats it up, essentially working against each other. This easily adds 30–50% to energy consumption.

Switching to an integrated HVACD system changes everything. It handles all these loads together, achieving much higher efficiency. Ultimately, it directly lowers your production cost per pound of dried flowers.

Why Split AC + Dehumidifiers Don’t Work

The classic setup—split AC units paired with standalone dehumidifiers—might look fine on paper, but in a real grow room it often turns into a mess. The biggest problem is that these two systems simply weren't designed to work together, and their control logic ends up fighting itself more than anything else.

- Control Logic Conflict:

- The AC is busy pulling down sensible heat, while the dehumidifier is basically throwing sensible heat right back into the room. It creates this tug-of-war where both systems keep pushing against each other, and your energy bill just keeps climbing.

- Nighttime Control Failure:

- Once the lights go off and temperatures drop, the AC shuts down—instantly wiping out the sensible load. But the plants don’t stop transpiring just because the room cooled down. Latent load keeps rising, humidity shoots up fast, and suddenly you're dealing with a mini humidity crisis.

- Unstable VPD:

- These systems only chase temperature and RH values. They don’t actually manage VPD, which means the environment is always a bit unstable, especially during transitions.

How an Integrated HVACD System Fixes Everything

An integrated HVACD unit gets rid of all that back-and-forth by treating the whole room as a single thermal system instead of a bunch of separate parts.

- Unified Load Management:

- Sensible and latent heat are handled together, so you don’t get that “one system undoes the other” situation.

- Hot Gas Reheat:

- Instead of overcooling the room during dehumidification, the system recovers internal heat and uses it for reheating. This keeps humidity steady without freezing out the plants.

- One Control Brain:

- Temperature, humidity, VPD, CO₂ levels, airflow—they all run under one coordinated logic. Everything stays in sync, and the environment stops swinging around on its own.

Advanced Control Logic for VPD Stability

Grow room hvac system control isn't just an “On/Off.” It's a real-time, micro-adjustment system too.

Dew Point Control is the Professional Standard

Relative Humidity (RH) fluctuates whenever the temperature changes. A professional commercial grow room HVAC system uses Dew Point as its core metric. By tracking dew point, the system can trigger dehumidification before the RH spikes, avoiding the lag time common in traditional sensors.

Airflow Engineering in Commercial Grow Rooms

Airflow is often the most overlooked part of cannabis hvac design.

The Problem:

- Microclimates

- Poor airflow creates "dead zones" where humidity accumulates. These microclimates are breeding grounds for Powdery Mildew and Botrytis.

The Solution:

- Top Supply → Side Return: Optimizes circulation.

- Strategic Return Placement: Return vents must be placed near heat and moisture sources (usually near lights and the lower canopy).

- Pressure Management: Maintain slight positive pressure to keep outside contaminants out, or neutral pressure to prevent cross-contamination.

Energy Efficiency & ROI

In high-density commercial grows, HVAC and dehumidification aren’t just background systems—they’re usually the biggest energy users in the entire facility. In many cases, they chew through 30–50% of your total electricity bill. That means they’re not just “support equipment”—they directly shape your margins.

And the pattern shows up everywhere. Reports from the Colorado Energy Office, SWEEP, and RII all point to the same reality:

- Most facilities burn around 1,300–2,000 kWh of electricity for every pound of dry flower.

- Really aggressive, high-intensity grows can push over 5,000 kWh+ per pound.

- A huge chunk of this comes from dehumidification—the latent load is no joke.

You can see the difference even more clearly when you compare actual setups:

- Split AC paired with standalone dehumidifiers: These systems start with a high energy baseline, and their efficiency tanks whenever nighttime loads swing dramatically.

- Integrated HVACD systems: Because they use heat recovery, unified control logic, and full-system load management, they can cut overall energy usage by 30–40%.

Both Desert Aire and Anderson Porter & Associates back this up: integrated HVACD consistently outperforms the “AC + dehu” combo, delivering that same 30–40% energy savings in real operations.

Conclusion: Stability, Compliance, and Efficiency

To judge whether a cultivation room's HVAC system is truly professional, it's not about the equipment's appearance, but whether it can interpret biological loads, keep pace with photoperiod cycles, stabilize VPD, and suppress nighttime humidity spikes.

These are the factors that truly determine a system's credibility.

If your goal is to ensure stable facility operation, pass audits without fail, and keep energy consumption under control, there's really only one option in such high-load, fully sealed environments—an integrated HVACD system. Traditional piecemeal systems simply cannot meet these demanding requirements.

Still Struggling with HVAC Sizing?

Temperature and humidity control in a commercial grow room leaves no room for guesswork. If you are unsure what equipment capacity you need to handle that dangerous nighttime humidity spike, let us calculate it for you.

Don't guess—Get a precise calculation.

Simply tell us your room details (dimensions, lighting, plant count), and Altaqua experts will provide you with a precise cooling and dehumidification load calculation and equipment recommendation within 24 hours.

Share with your friends:

Popular Blogs on Altaqua:

Download Catalogue