Grow Room HVACD: A Smarter Climate Control Solution for Commercial Growers

Updated: Jan. 15, 2026 · 6 min read

HVAC systems are not unfamiliar to most people. As the name suggests, they refer to heating, ventilation, and air conditioning systems. Commercial HVAC systems are often used in large buildings such as hotels and office towers. Over time, these proven systems have also been applied to new fields like commercial cannabis cultivation.

Although traditional HVAC systems usually include a dehumidification function, they cannot meet the crucial dehumidification needs required to keep plants healthy in indoor grow spaces. To emphasize the importance of dehumidification when selecting HVAC systems, more climate experts and growers now use the term HVACD, which stands for heating, ventilation, air conditioning, and dehumidification.

Forum Discussion about HVAC System Suggestions

On social platforms like Reddit, we often see growers asking questions such as:

“My father-in-law owns an indoor cannabis farm and is expanding into a new 4000 sq ft building. Each grow room will have around 180k BTU load. We need to remove the moisture, offset the heat from the lights, and bring in fresh air. The current setup uses two turbine fans for fresh air, three mini-splits for cooling, and separate dehumidifiers. Are there better options for the new building?”

Some users replied:

“If this is a ‘hobby’ Mini-Splits will be ‘fine’. If this is anything professional I'd recommend trying one of those small units from Agronomic IQ. The more I read up about this, the more I realize just how crazy sensitive the environment is for these plants.”

“Look up Cultvia systems, indoor agricultural HVAC systems. I'm sure there are more types of these businesses out there, but I'm a bit familiar with this one.”

From these conversations, what you’ll find is most growers start to think traditional when it comes to environmental control: mini-splits paired with standalone dehumidifiers. But as the grow scale rises or you need to tolerate consistent temperature and humidity, they soon bump up against the ceiling of traditional setups. This is why grow room HVACD is becoming an important focus. They combine the capabilities of conventional HVAC and dehumidifier with greatly enhanced levels of moisture removal.

In other words, we do not deny that mini-splits or separate dehumidifiers can work. But if the goal is to create a high-yield, controllable, and energy-efficient grow environment, choosing a grow room HVACD is clearly the better option.

Traditional HVAC Systems & Integrated HVACD Systems Compared

In the previous section, we mentioned that many growers gradually realize the limits of traditional HVAC setups in grow spaces. This view is further supported by a report titled The Cultivation HVACD System Comparison Study, conducted by Anvil Agronomics, Zartarian Engineering, and Anderson Porter Design.

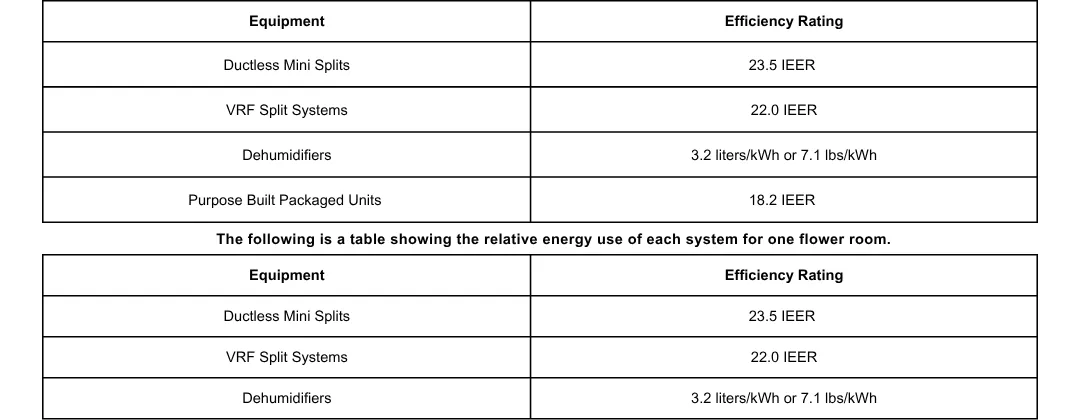

The study compared three systems in terms of energy efficiency, control level, and temperature and humidity stability:

System 1: Eight 4-ton ductless ceiling-hung evaporators with remote condensers for sensible load, plus seven 706-pint standalone dehumidifiers (82°F / 58% RH) for latent load removal.

System 2: Four 8-ton VRF Split Fan coils with matching remote condensers for the sensible load and seven 710-pint dehumidifiers to control the latent load.

System 3: Two 20-ton package Integrated HVACD units with full reheat coils and the ability to vary the sensible heat ratio.

The results show that the VRF split system uses the most energy, about 626,836 kWh per year. The integrated HVACD system uses the least energy, about 14% less than the ductless split system and 16% less than the VRF system. Even though VRF and small ductless systems are more efficient by themselves, they rely on less efficient standalone dehumidifiers, which increases overall energy consumption.

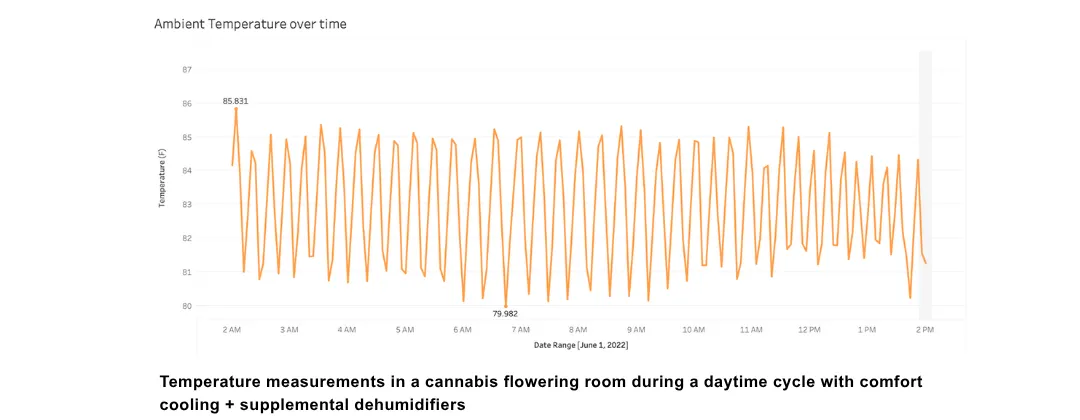

The study also compared performance in two real grow rooms.

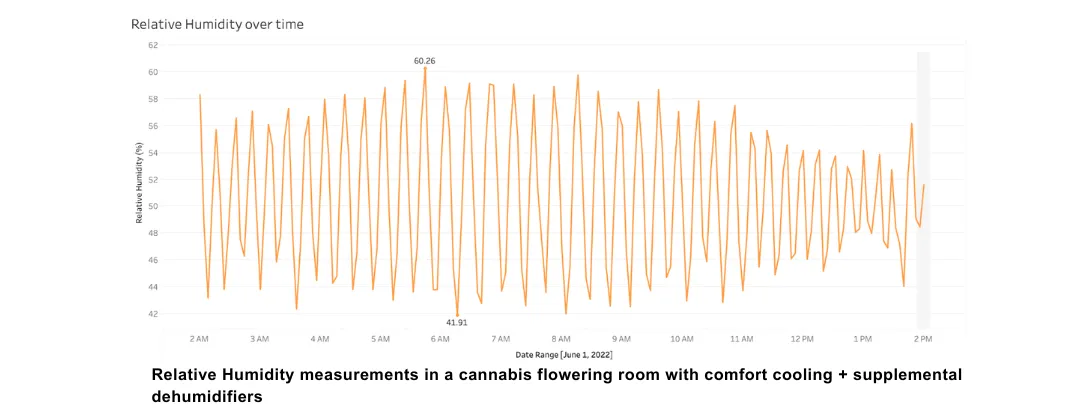

- 1, One 720 sq ft grow room used mini-splits with standalone dehumidifiers. Temperature fluctuated ±2.5°F, and humidity fluctuated ±10% RH. The system cycled frequently, and temperature and humidity control interfered with each other. Plants grew unevenly, were prone to powdery mildew, and yield and quality decreased significantly.

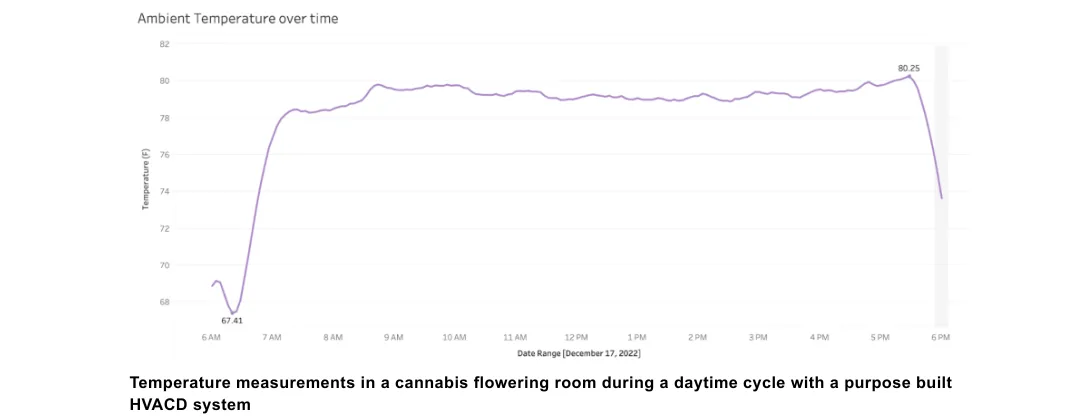

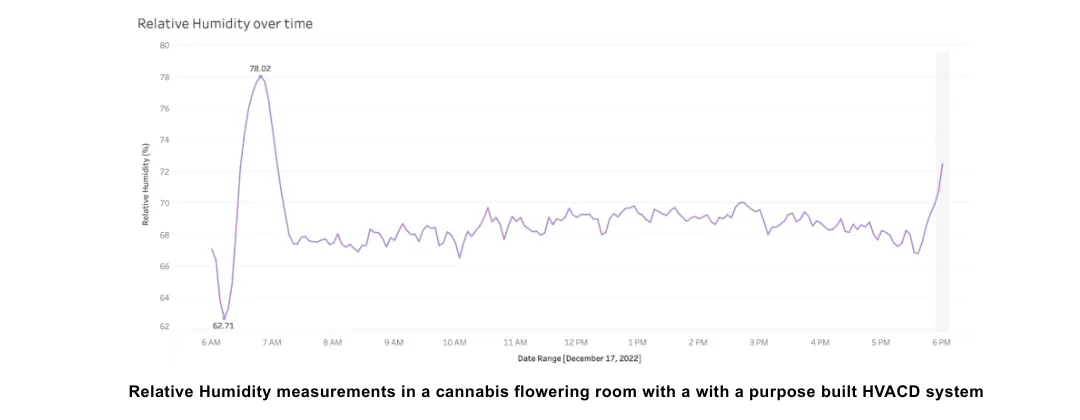

- 2, Another 3,456 sq ft grow room used a single integrated HVACD unit. Temperature fluctuated less than ±1°F, and humidity fluctuated about ±2.5% RH. The environment was stable, plants grew healthier, and yield and profit increased significantly. The system was also easier to control and required fewer units.

These results provide data to support growers’ experiences and scientific evidence for the advantages of grow room HVACD. HVACD meets the high-precision environmental needs of modern commercial grow rooms and aligns with energy efficiency and sustainability trends.

Based on these findings, the next section will analyze in more detail how grow room HVACD outperforms traditional systems in temperature, humidity control, and energy efficiency.

Degree of Temperature and Humidity Control

Conventional in home and business systems were developed for homes along with retail spaces. They exist to regulate the temperature in our interior environments (with only moderate assistance when it comes to humidity). Temperature or humidity changes are not a big problem for residential use. However, such control would not be able to satisfy the plants’ sensitive environmental requirements in commercial grow spaces.

Grown indoors, the heat and moisture load on plants varies with the light cycle. Grow lights and machinery generate significant heat during the day. The HVAC system is on 24/7 to keep it cool and dehumidified. During the heat-load decrease at night, when lights go off, for the traditional systems once that very preset temperature is achieved it stops. The temperature is cool, but plants continue to transpire and release water into the air, driving up humidity. As it is in air conditioner OFF state, dehumidifying operation stops and humidity control cannot be performed efficiently. This results in very frequent temperature and humidity changes.

These fluctuations disrupt VPD balance. They decrease transpiration and nutrient absorption, thus reducing the efficiency of photosynthesis, crop quality and yield.

HVACD systems are all-in-one commercial cultivation solutions designed specifically for growing. Meanwhile, they converge cooling and heating and ventilation,and dehumidification as a main work.

It can be operated 24/7 and switch modes automatically for various growth stages. During the day it concentrates on cooling and dehumidification. At night, it equalizes climate with dehumidification and temperature control.

This fine control helps to maintain temperatures and humidity constant, guarantees optimal VPD throughout its entire cycle and results in greater production, better quality and more predictable profit.

Energy Consumption

In grow rooms, energy consumption is always the largest part of operating costs. For most growers, electricity costs, especially for HVAC systems, are usually second only to labor. Traditional HVAC systems are not designed for grow environments. They often need to work with standalone dehumidifiers to control both temperature and humidity.

This combination is often inefficient. Gaining air cooling through split air conditioner. A standalone dehumidifier gives off heat as it operates, so that cancels out the cooling. The constant struggle between the two depletes energy and causes regular temperature and humidity fluctuation. This raises the operating load and energy expenses.

Grow room HVACD can recover heat from the refrigeration process to reheat dehumidified air, avoiding overcooling and keeping grow room temperatures stable during dehumidification. Hot gas reheat technology captures the heat generated during dehumidification and uses it to reheat the cooled, dry air before sending it back into the grow room. This process minimizes additional heating energy consumption while maintaining an ideal balance of temperature and humidity.

Plus, HVACD heating is “free.” This is gained from the surplus heat produced during dehumidification and makes it possible to reduce additional heating. With hot gas reheat, the system offers tight control over conditioning and reduces energy consumption as well as operating expenses. Growers in doing so, gain all the advantages of energy efficiency and sustainability.

Conclusion

From the evaluation made above, it can be seen that grow room HVACD is better than conventional HVAC systems. They follow plant growth patterns more closely and waste less energy. Integrated with a intelligent control strategy, It is able to manages temperature and humidity precisely, power saving and operates stably. This provides commercial growers with a more manageable, affordable and consistent climate solution.

FAQ 1: What is the difference between traditional HVAC and HVACD in grow rooms?

Traditional HVAC systems are designed for human comfort and mainly focus on temperature control, offering only limited humidity regulation. In grow rooms, humidity can rise quickly when lights turn off, and traditional systems stop running once temperature is satisfied — leading to unstable VPD, mold risks, and inconsistent yields.

HVACD systems integrate cooling, heating, ventilation, and dedicated dehumidification. They can run continuously and automatically balance temperature and humidity day and night, providing the precision needed for commercial plant cultivation.

FAQ 2: Why do growers transition from mini-splits and standalone dehumidifiers to HVACD solutions?

Mini-splits + standalone dehumidifiers can do the job for a small or hobbyist grow, but they will tend to struggle with large, commercial growing operations. Discrete systems often work at cross-purposes — AC cools and dehumidifies, the latter byproduct that can make you feel cooler while increasing energy waste and climate swings.

Not your basic HVAC HVACD systems offer better climate control, efficiency and automation leading to healthier plants, increased yield, lower operating costs and fewer pieces of equipment to maintain.

FAQ 3: Are HVACD systems more energy-efficient than VRF or split systems?

Yes. Studies show integrated HVACD systems can use 14%–16% less energy than ductless split and VRF systems in commercial cultivation settings.

That’s because HVACD units recover heat generated during dehumidification and reuse it for reheating or temperature balancing. This reduces compressor workload and avoids the energy conflict seen in setups using separate AC and dehumidification equipment.

Share with your friends:

Popular Blogs on Altaqua:

Download Catalogue