Grow Room Temperature Control: Why Temperature Drifts Even When HVAC Is Running

Updated: Jan. 8, 2026 · 6 min read

Abstract: In commercial grow rooms, temperature problems rarely start with the setpoint. Many growers discover that even when HVAC systems are running, room temperature still drifts. This article explains why grow room temperature control often fails at the system level, how humidity and control logic override temperature targets, and what stable temperature control really requires in modern grow room HVAC design.

If you run a commercial grow room, you’ve probably had this moment before:

the HVAC is on, the system status looks normal, setpoints are dialed in—yet the room temperature still won’t stay where you want it. It creeps up. It drops off. Sometimes it looks fine on the controller, but the plants tell a different story.

This is where most growers start chasing numbers. Adjust the setpoint. Tighten the deadband. Move the sensor. Try again tomorrow.

But in reality, grow room temperature control problems almost never start at the setpoint level. This is exactly why many commercial growers eventually move toward grow room HVAC systems designed for temperature and humidity control, rather than relying on comfort cooling alone.

Why Grow Room Temperature Drifts Even When HVAC Is Running

Let’s clear up one common misunderstanding right away:

HVAC running does not automatically mean the grow room is under control.

In commercial grow rooms, temperature drift is usually not caused by equipment failure. The system is doing exactly what it was designed to do—just not what the grow room actually needs.

HVAC Running ≠ Room Temperature Controlled

When growers say, “The HVAC is working,” they usually mean compressors are on, fans are spinning, and the controller shows active cooling or heating. From a mechanical standpoint, that’s true.

From a room standpoint, it’s often irrelevant.

Grow rooms are not uniform spaces. Poor airflow distribution in commercial grow rooms often exaggerates temperature differences across the canopy. Temperature changes vertically through the canopy, horizontally across the room, and dynamically as plants transpire. A sensor mounted on the wall or in a return duct only sees a small slice of reality. Meanwhile, leaf surfaces experience something completely different.

That’s why you’ll often see this mismatch:

- Controller says temperature is on target

- Plants behave like they’re stressed

- Growth patterns become inconsistent

The HVAC is running, but the room itself is never truly stable.

Grow Room Temperature Is Not the Same as Setpoint Temperature

This is a subtle but critical point. The setpoint is only a target—it’s not a guarantee.

Actual grow room temperature is influenced by several factors working at the same time:

- Air distribution and mixing quality

- Latent heat from plant transpiration

- How the HVAC system prioritizes its control actions

In many systems, temperature control is constantly being compromised by other demands, especially humidity. So even if the setpoint never changes, the real room conditions drift because the system is busy solving a different problem.

Once you see that distinction, a lot of confusing behavior suddenly makes sense.

The Real Reason Temperature Control Fails: Control Logic, Not Capacity

When temperature won’t hold, the first instinct is to blame capacity. Maybe the unit is undersized. Maybe the lights added more load than expected.

Sometimes that’s true—but far more often, the capacity is there, and the control logic is the problem.

Humidity Priority Overrides Temperature Control

In commercial grow rooms, humidity is never optional. Plants are constantly releasing moisture into the air, especially during peak growth and flowering. That latent load doesn’t pause just because the temperature looks fine.

Many HVAC systems respond to this by prioritizing dehumidification,which clearly shows how humidity control affects grow room temperature in real grow room HVAC operation. And here’s the catch: in most traditional setups, dehumidification only happens through cooling.

So when humidity rises:

- The system increases cooling

- Air temperature drops below target

- Room temperature drifts away from the setpoint

From the controller’s perspective, this is acceptable behavior. From a grower’s perspective, it’s maddening.

Why Temperature Drifts Even Though Cooling Capacity Is Sufficient

This is where a lot of growers get stuck. The unit has plenty of cooling power, yet temperature control still feels sloppy.

The reason is runtime behavior. Systems designed around comfort cooling tend to:

- Shut down as soon as the temperature setpoint is reached

- Restart frequently when humidity rebounds

- Short-cycle under mixed loads

The result is a constant tug-of-war. Temperature control never settles because the system is being pulled around by humidity demands. Capacity isn’t the limiting factor—control priority is.

Why Traditional HVAC Control Logic Causes Grow Room Temperature Instability

To understand why this happens so consistently, you have to look at where traditional HVAC logic comes from.

Comfort Cooling Logic Doesn’t Match Grow Room Loads

Most HVAC control strategies were built for offices, retail spaces, or homes, following traditional comfort assumptions outlined in ASHRAE guidance on HVAC system design. They assume:

- Fairly stable heat loads

- Predictable occupancy patterns

- Humidity as a secondary concern

Grow rooms are the opposite. They deal with:

- High latent loads from plants

- Rapid load changes at lights-on and lights-off

- Tight environmental tolerances

When comfort-based control logic is dropped into a grow room, instability isn’t a surprise—it’s inevitable.

Temperature Control Breaks When Dehumidification Is Tied to Cooling

As long as dehumidification depends on cooling, temperature control will always be compromised.

Here’s the typical sequence:

- Cooling runs to remove moisture

- Temperature hits the setpoint

- System shuts down

- Humidity rebounds

- Temperature drifts again

From the outside, it looks like poor tuning. In reality, it’s a structural limitation of the control approach.

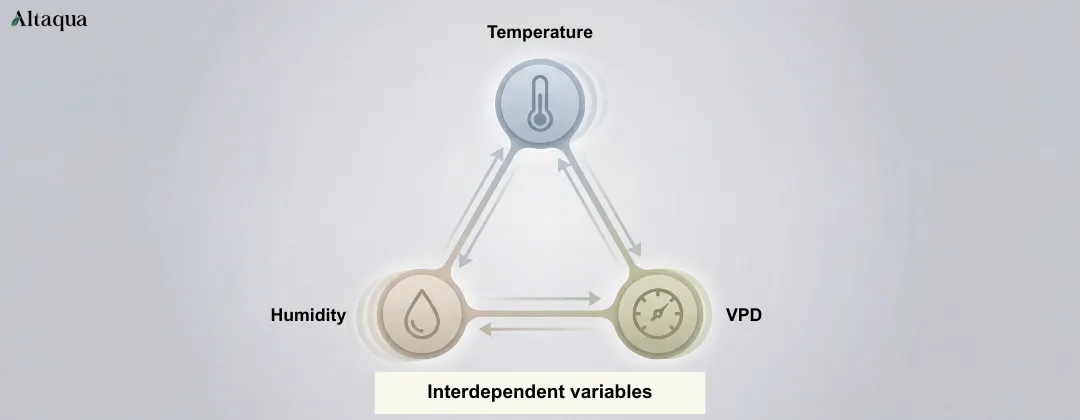

Temperature, Humidity, and VPD: Why They Drift Together

At this point, many growers start watching VPD more closely, hoping it will clarify what’s happening. Understanding VPD in commercial grow rooms often reveals why temperature and humidity drift together.

Temperature Drift Is Often a Symptom of Humidity Instability

When humidity isn’t stable, temperature ends up compensating for it. The system cools more than necessary, then stops too soon, then starts again. Temperature drift becomes the visible symptom of a hidden humidity problem.

That’s why grow room climate instability is rarely caused by a single variable. Temperature, humidity, and VPD move together because the system is controlling them together—whether you want it to or not.

Why VPD Looks Wrong Even When Temperature Seems Acceptable

You can hit a temperature number and still miss the environment completely.

Short-term temperature readings may look fine, but leaf-level conditions remain unstable. Transpiration fluctuates. VPD drifts. Plant response becomes inconsistent.

In that sense, VPD drift isn’t the root cause. It’s the outcome of a system that never fully stabilizes.

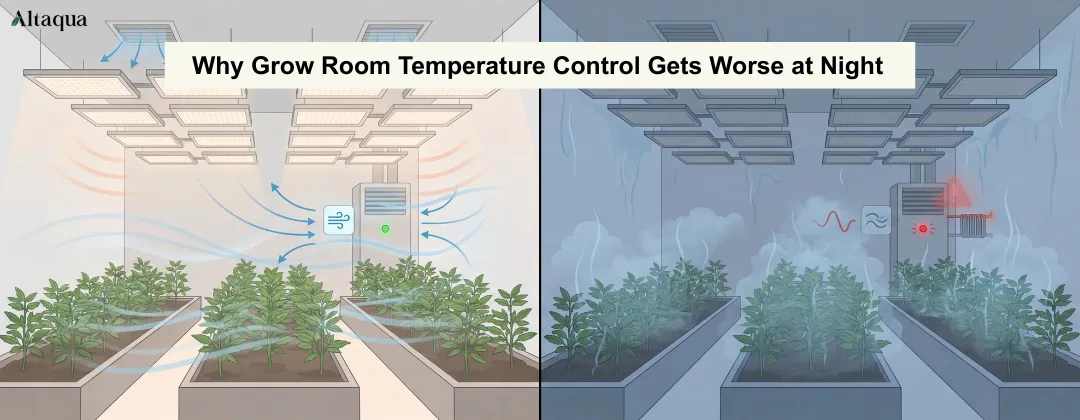

Why Temperature Drift Gets Worse at Night

If temperature control feels hard during the day, it often feels impossible at night. These nighttime temperature and humidity control challenges expose limitations in traditional HVAC control logic.

Lights-Off Load Changes Expose Control Weakness

When lights turn off, sensible heat drops quickly. But plants don’t stop transpiring right away. Latent load remains, sometimes for hours.

Many HVAC systems simply aren’t designed to handle that combination. They lose the ability to remove moisture without overcooling, and temperature control falls apart.

Nighttime Temperature Drop Is a System Design Limitation

This isn’t a parameter problem. You can tweak night setpoints all you want, but if the system’s operating range doesn’t match nighttime conditions, drift is unavoidable.

Nighttime instability is one of the clearest signs that the HVAC control logic doesn’t align with real grow room behavior.

When Temperature Drift Can’t Be Fixed by Adjusting Settings

At some point, every grower reaches this realization: no amount of fine-tuning seems to stick.

Signs Your Temperature Problem Is Structural

A few patterns show up again and again:

- Temperature stabilizes briefly, then humidity spikes

- Nights are always worse than days

- HVAC runs hard but never feels settled

These aren’t tuning issues. They’re system-level limitations.

Why Fine-Tuning Setpoints Only Delays the Problem

Adjusting setpoints can buy time, but it doesn’t change how the system makes decisions. Control logic stays the same, so the same conflicts keep returning.

Eventually, the drift comes back.

What Stable Grow Room Temperature Control Actually Requires

True grow room temperature control starts when temperature is allowed to be temperature—nothing more, nothing less.

Decoupling Humidity Control from Temperature Control

When humidity control no longer depends on overcooling, temperature finally has room to stabilize. The HVAC system can run longer, smoother cycles without constantly overshooting.

That’s when “control” starts to feel real.

Control Logic Designed for Grow Room Reality

Stable systems are built around how grow rooms actually operate:

- Continuous, predictable runtime

- Smooth transitions between day and night

- Different control strategies for different room types

Not templates. Not comfort logic. Real grow room logic.

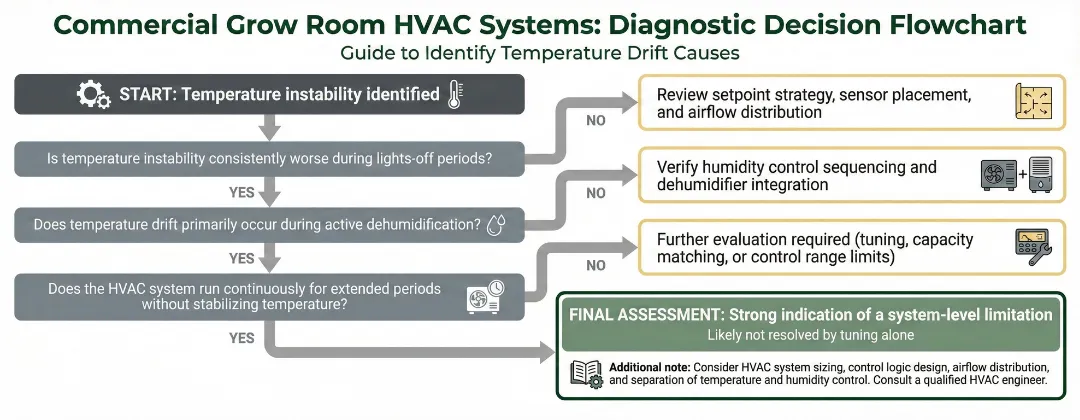

How to Diagnose the Real Cause of Temperature Drift in Your Grow Room

Before replacing equipment, it’s worth stepping back and asking the right questions and diagnosing grow room HVAC system limitations at the system level.

Questions to Ask About Your Current HVAC Control Logic

- Is temperature control being overridden by humidity demands?

- Does the system short-cycle throughout the day?

- Does nighttime control feel fundamentally weaker than daytime?

If the answer is yes, the issue is already clear.

When It’s Time to Rethink the System, Not the Equipment

Equipment running does not mean the environment is controlled.

When temperature drift keeps returning, the problem usually isn’t hardware—it’s how the system thinks.

And once you see that, grow room temperature control stops being a guessing game and starts becoming a design problem you can actually solve.

FAQ

1、Why does my grow room temperature keep drifting even though the HVAC system is running?

This is one of the most common—and confusing—situations growers run into. In most cases, the issue isn’t that the HVAC system isn’t working. It’s that the system is busy solving a different problem, usually humidity.

When dehumidification is tied to cooling, temperature often gets pushed off target as a side effect. So even though the HVAC is running, real grow room temperature control never fully settles.

2、Can’t I fix grow room temperature problems by adjusting setpoints or controller settings?

Sometimes small adjustments help in the short term, but they rarely solve the root issue. Setpoints don’t change how the system makes decisions—they only change when it starts or stops.

If temperature keeps drifting, especially at night or during humidity spikes, it usually means the control logic itself is limiting stable grow room temperature control, not that the settings are slightly off.

3、Why is grow room temperature control harder at night than during lights-on?

At lights-off, sensible heat drops quickly, but plants keep releasing moisture. That combination exposes a weakness in many HVAC systems.

Without enough sensible load, the system struggles to remove humidity without overcooling, and temperature drops below target. This isn’t a tuning issue—it’s a sign the HVAC control strategy isn’t designed for real nighttime grow room conditions.

Share with your friends:

Popular Blogs on Altaqua:

Download Catalogue