HVAC Dry Cooler in Cannabis Cultivation: A Revolution in Cooling Technology

As the cannabis cultivation industry continues to flourish, the criticality of creating the ideal growth environment becomes increasingly evident. Among the emerging innovations, the HVAC dry cooler stands out, symbolizing the industry's shift towards efficient, sustainable, and cost-effective solutions. This blog aims to navigate the intricate world of cooling systems, providing insights into their significance, their evolution, and their role in shaping the future of cannabis cultivation.

This comprehensive exploration will traverse the depths of both traditional and modern cooling systems, offering readers an understanding of their functionalities, benefits, and challenges. By comparing systems like cooling towers with HVAC dry coolers, cultivators can discern the most suitable solution for their specific needs.

Whether you're a seasoned cultivator or a newcomer to the field, this guide promises a wealth of knowledge, ensuring you're well-equipped to optimize your cultivation environment for the best yields.

Learning the Importance of Cooling Technology in Cannabis Cultivation

For cultivators, ensuring the health and productivity of the cannabis plant is of paramount importance. One cannot merely rely on water, soil, and light; the micro-environment where the plant thrives needs precise control. Temperature is among the critical components of this environment, and that's where cooling technology steps in. This section elucidates the integral role of cooling technology in cannabis cultivation.

Controlling Temperature for Optimal Growth

Every plant has a specific range of temperatures within which it thrives, and cannabis is no exception. High temperatures can disrupt the plant's cellular structures, affecting its metabolic processes. When cultivating cannabis, exposing the plant to excessive heat can introduce a series of complications. These include leaf wilt, reduced efficiency in photosynthesis, and potential harm to the trichomes, the plant's reservoirs for essential oils and cannabinoids. Moreover, an overly warm environment heightens the plant's vulnerability to diseases and pest infestations.

Cooling mechanisms employ specific agents like refrigerants to draw out and dissipate heat from the cultivation space. The heat is then expelled outside, ensuring the indoor environment remains at the desired temperature. Additionally, advanced cooling systems come equipped with sensors and automation. These systems can detect fluctuations in temperature and adjust accordingly, maintaining a consistent environment for the plant.

By using cooling technology, cultivators can simulate the ideal natural conditions cannabis plants experience, ensuring their health and maximizing their potential yield.

Managing Humidity to Promote Plant Health

Humidity levels have a direct impact on plant health. Plants risk dehydration when ambient air is too arid, compromising their growth trajectory. Conversely, an environment with too much moisture is a breeding ground for fungal issues like mold and mildew. By regulating temperature, cooling technologies help maintain suitable humidity levels, ensuring plants are not susceptible to these extremes.

Achieving Energy Efficiency in Cooling

Modern cooling systems have made strides in energy efficiency. They employ algorithms to understand the growing environment's needs, avoiding unnecessary energy consumption. This intelligent energy use reduces costs and minimizes the cultivation process's carbon footprint.

Preventing Pests and Diseases

Certain pests, like spider mites, thrive in hot, dry environments. Others, like fungi, prefer moist conditions. By managing temperature and humidity, cooling technologies reduce the chances of these pests and diseases. Keeping the environment stable and within desired parameters prevents the onset of conditions where these threats thrive.

Considering Winter Cultivation Challenges

Winter introduces challenges for cannabis cultivation, with dropping temperatures and fluctuating humidity levels. However, cultivators can maintain a stable indoor environment with cooling technology that integrates heating elements. This adaptability ensures consistent growth throughout the colder months. Enhancing Yield and Quality

Enhancing Yield and Quality

The ultimate goal of any cultivator is to produce a high yield of top-quality cannabis. An environment that's too hot, cold, humid, or dry can negatively impact yield and quality. Cultivators harness cooling solutions' capabilities to strike a balance in these variables, establishing an optimal environment. This ensures the plant thrives and, in turn, results in a crop that adheres to top-notch standards.

While the art of cannabis cultivation is complex, understanding and implementing effective cooling technology simplifies the journey. It equips growers with the tools necessary to overcome environmental challenges and ensures the best possible outcome for their crops.

Types of Traditional Cooling Systems

After intensive research, cooling technology has an indispensable impact on the success of cannabis cultivation. However, this importance didn't come out of nowhere but emerged over time. Let's look back at the evolution of cooling technology in cultivation.

In the early stages of cooling technology, most growers relied on natural methods to regulate the temperature of the growing environment. For example, they might grow during mild weather or use shade nets and traditional fans to dissipate heat. These methods, while simple, were limited in effectiveness and reliability.

With the Industrial Revolution's advent, significant cooling technology advances were made. Growers during this period began experimenting with mechanical cooling methods, such as early chillers and simple cooling towers. While preliminary, the advent of these devices marked the beginning of a new era: growers began to be able to more precisely control environmental conditions to meet the specific needs of their plants.

As technology evolved into the 20th and 21st centuries, modern cooling systems, such as HVAC dry coolers, began to be widely used in cultivation. These advanced cooling solutions provide constant and consistent temperature and humidity control and are more energy-efficient and environmentally friendly.

Before we get into the details of traditional cooling systems, it's important to understand their development in historical and modern contexts for a holistic understanding. And now, let's take a closer look at the various types of conventional cooling systems.

Cooling Tower

Cooling towers predominantly employ the principle of evaporative cooling. The mechanism involves circulating water, which has absorbed heat from processes or equipment. This warm water is then released into the atmosphere, usually within a tower-like structure. When some of the water evaporates, it releases latent heat, which results in the cooling of the water left behind. This approach stands out for its energy efficiency, largely because it utilizes evaporation for cooling. However, the consistent maintenance required to deter bacterial growth is a challenge. Additionally, the system may lead to higher water usage due to losses through evaporation.

Chiller

Chillers extract heat from a liquid, utilizing either a vapor-compression or absorption refrigeration cycle. The subsequently cooled liquid travels through a heat exchanger to cool equipment or ambient air. In cultivation settings, chillers can control the water temperatures in systems like hydroponics. Their precision in temperature control is commendable, making them apt for both micro and macro operations. Conversely, they can be energy-hungry, necessitating continuous monitoring for optimal functionality.

Water Cooler

Water coolers employ a refrigeration cycle to absorb heat from the water, releasing it into the external environment ensuring that irrigation water remains within a set temperature range. Their consistency in maintaining water temperatures and operational simplicity are noteworthy. Yet, they face limitations in their cooling capacity when contrasted with more extensive systems. Also, without proper upkeep, there's a risk of bacterial growth.

Condenser

Condensers are integral to most refrigeration processes. Their primary role is to cool and condense vapor into its liquid form after it has been heated, ensuring heat is effectively dissipated. Their proficiency in heat removal and adaptability to diverse cooling setups stands out. However, due to their constant operation, they can be susceptible to wear and tear. For efficient operation, a conducive ventilation environment is also essential.

Heat Exchanger

Heat exchangers specialize in transferring heat between two fluids without any direct contact. In cultivation, they might be employed to tweak the temperature of a nutrient solution indirectly. Their design ensures an efficient heat transfer mechanism, reducing contamination risks between the fluids. However, their intricate design can occasionally pose maintenance challenges, and if not cleaned methodically, their efficiency might be compromised.

In conclusion, environmental variables, especially temperature, significantly affect the crop's outcome while cultivating. With their distinct attributes, traditional cooling systems offer invaluable tools for cultivators.

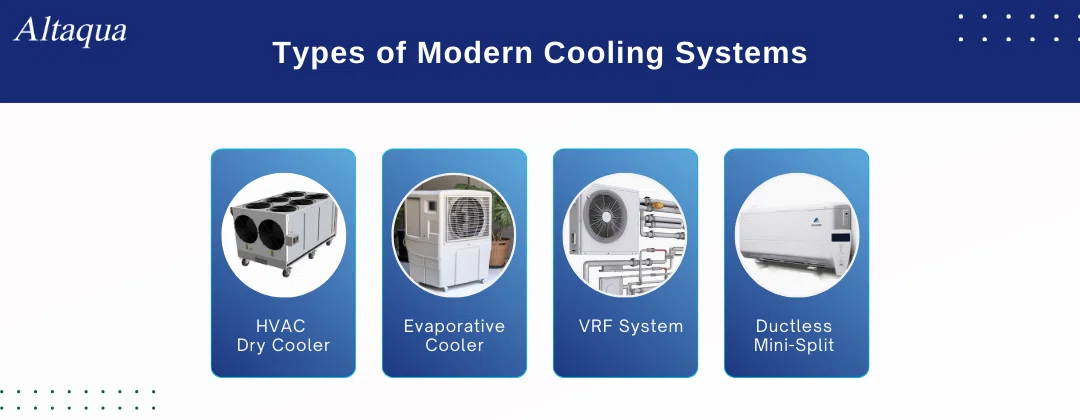

Types of Modern Cooling Systems

The continuous quest for efficiency and technological advancements have birthed modern cooling systems. While leveraging some principles from their traditional counterparts, these systems introduce novel methodologies to enhance performance and energy conservation.

HVAC Dry Cooler

One of the most notable innovations in modern cooling is the HVAC dry cooler. Unlike traditional methods that rely on water or other liquids, this system employs air to dissipate heat. As air flows over the heated coils, it absorbs the warmth and effectively cools down the surrounding environment.

Using air eliminates the need for a water source, reducing potential water-related issues. Additionally, this system's "dry" nature ensures minimal moisture-related complications, making it a prime choice for locations with water scarcity or for those prioritizing water conservation. However, it might not be as effective in extremely humid conditions, where the air's capacity to absorb heat is limited.

Evaporative Cooler

While not entirely new, the evaporative cooler has been refined to fit the modern context. It allows water to evaporate, which naturally cools the surrounding air.

While this method is inherently energy-efficient, modern enhancements have optimized its performance, enabling it to provide substantial cooling with less water consumption. It shines particularly in dry climates, where its operation can be highly effective and sustainable. However, its efficiency might decrease in areas with high humidity as the air becomes saturated and less receptive to additional moisture.

Variable Refrigerant Flow (VRF) System

The VRF system introduces a level of precision unheard of in traditional systems. Controlling the amount of refrigerant flowing to various parts of the system offers precise temperature regulation, adapting to the specific needs of different areas within a facility.

This adaptive mechanism not only ensures optimal comfort but also enhances energy efficiency. However, initial installation costs can be higher compared to other systems. Additionally, its intricate nature requires specialized maintenance to ensure longevity and optimal functioning.

Ductless Mini-Split

The ductless mini-split system breaks away from the conventional duct-dependent systems. It comprises an outdoor compressor and multiple indoor air-handling units. By eliminating the need for ductwork, it offers a flexible solution for spaces where installing ducts might be challenging or impractical.

This system conserves energy by providing tailored cooling, ensuring that each facility section receives the exact amount of cooling required. On the downside, each indoor unit requires individual installation, potentially increasing labor costs, and the aesthetic appeal of multiple indoor units might not be to everyone's liking.

In summary, the development of modern cooling systems underscores the industry's pursuit of enhanced efficiency and adaptability. Systems, like the HVAC dry cooler and others mentioned above exemplify the strides made in catering to varying environmental and operational needs. It's evident that as technological advancements persist, the approaches to cooling will further evolve to meet diverse challenges and requirements.

Cooling Towers in Traditional Cooling Systems vs. HVAC Dry Coolers in Modern Cooling Systems

In our exploration of cooling systems, it's evident that technological advancements are ever-evolving. Having delved into traditional and modern cooling systems, our focus now shifts to a comparative analysis. In the following sections, we'll closely examine the nuanced differences between cooling towers prevalent in traditional systems and HVAC dry coolers characteristic of modern cooling systems.

The Underlying Principles

To truly grasp the distinctions between cooling towers and HVAC dry coolers, one must first understand their core operating principles, which are rooted in thermodynamics and heat transfer mechanics.

Evaporative Cooling in Cooling Towers

Cooling tower systems use water to remove waste heat, primarily through evaporation. The main components include the cooling tower, pump, and heat exchanger. Water absorbs heat in the exchanger, then flows over the tower, interacting with air, causing evaporation and heat transfer. This process cools the water, which is recirculated through the heat exchanger to repeat the cycle.

Air-Based Heat Rejection in HVAC Dry Cooler

On the other hand, HVAC dry coolers operate using air-to-air or air-to-fluid heat exchangers. The fluid, often a refrigerant, passes through coils where ambient air is directed over them. Heat transfer from the fluid to the air occurs without phase change or water evaporation. This ensures a stable and consistent cooling process independent of external water resources.

Efficiency and Energy Consumption

The crux of any cooling mechanism lies in its efficiency and energy consumption, dictating its environmental and economic implications.

Water and Power Consumption in Cooling Towers

By design, they rely heavily on water evaporation to dissipate heat. This process, although effective, results in substantial water consumption. On average, cooling towers can lose thousands of gallons of water daily due to evaporation, drift, and bleed-off. This makes them water-intensive and increases the burden on water treatment facilities due to the constant need for water replenishment. Electrically, cooling towers' pumps, fans, and other associated equipment consume significant power, leading to higher operational costs.

Reduced Energy Demands with HVAC Dry Cooler

On the other hand, the HVAC dry cooler offers a more eco-friendly approach. These units utilize ambient air to cool the fluid, eliminating the need for large water reservoirs. The absence of an evaporative process significantly curtails water consumption. In terms of energy, HVAC dry coolers optimize fan speeds and use efficient heat exchangers, thus requiring less electricity than traditional cooling towers, especially during peak operational hours.

Maintenance and Longevity

With longevity in mind, maintenance becomes a vital aspect of any cooling system's life cycle, influencing its operational efficacy and total cost of ownership.

Challenges with Scaling and Algae in Cooling Towers

Due to their water-intensive nature, cooling towers often face issues like mineral scaling from hard water evaporation. This mineral build-up can drastically reduce the system's efficiency, necessitating regular descaling processes. Furthermore, the warm, moist environment is a haven for algae and bacteria, leading to blockages, system inefficiencies, and even health concerns, requiring rigorous water treatment and periodic clean-ups.

Minimal Upkeep and Durable Design of HVAC Dry Cooler

HVAC dry coolers have been designed to address some limitations observed in traditional cooling systems. They operate in a closed-loop system, which minimizes exposure to external contaminants, thus reducing the potential for fouling and system degradation. This design inherently requires less regular maintenance than open-loop systems like cooling towers. Moreover, the absence of an evaporative process means there's no water treatment required, a significant ongoing cost in cooling towers.

Environmental Impact

When it comes to the environment, every piece of technology and its operations can influence it in some manner. Cooling technologies, particularly the traditional cooling towers and HVAC dry coolers, have distinct environmental impacts.

Water Usage and Treatment in Cooling Towers

Traditional cooling towers consume a considerable amount of water, primarily because they rely on the principle of evaporation to dispel heat. This frequent water consumption necessitates regular replenishment, leading to high water use. Additionally, chemical treatments are often required to maintain water quality and prevent microbial growth or scaling. These treatments can have environmental repercussions, especially if there is unintentional leakage or spillage, potentially harming aquatic ecosystems.

HVAC Dry Cooler: Water-Saving and Environmentally Friendly

In stark contrast, the HVAC dry cooler champions water conservation. Operating without the need for evaporation, it drastically reduces water consumption. This conserves a vital natural resource and eliminates the need for chemical water treatments, further reducing its environmental footprint. Given today's emphasis on sustainable solutions, the HVAC dry cooler is an environmentally friendly choice in the cooling technology world.

Cost Implications Over Time

When considering a cooling solution beyond the initial investment, one must also contemplate the ongoing expenses of operation, maintenance, and potential repairs.

The Cumulative Cost of Operating Cooling Towers

Operating a cooling tower comes with several recurring expenses. Water replenishment, chemical treatments, and periodic maintenance tasks – like cleaning, descaling, and addressing microbial growth – can quickly add up. Furthermore, in areas with water scarcity, the water cost can significantly contribute to operational expenses. There's also the cost of energy consumption to factor in, especially if the cooling tower is serving a large facility or operating continuously.

Cost Benefits of HVAC Dry Cooler in the Long Run

Opting for an HVAC dry cooler might seem like a significant investment initially, but its long-term economic advantages become evident as time progresses. With minimal water usage, the costs associated with water replenishment and treatment are virtually eliminated. While periodic maintenance is still necessary, it tends to be less frequent and less intensive than with cooling towers. Moreover, with many HVAC dry coolers designed for energy efficiency, power consumption can be considerably lower, translating to savings on electricity bills. Over several years, these savings can offset the initial investment, making HVAC dry coolers a cost-effective solution in the long run.

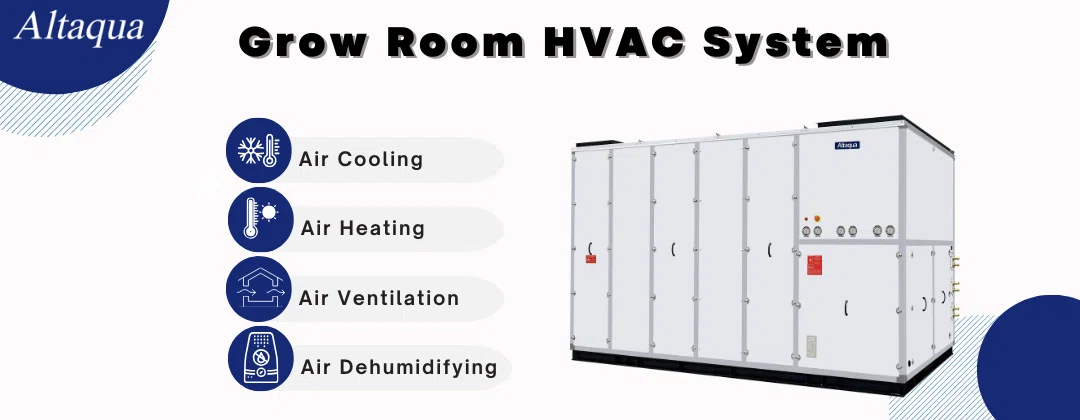

Integrated HVAC Systems Solution for Cannabis Cultivation

The trajectory of modern cooling technology offers a vivid representation of human ingenuity. As the quest for precision and efficiency persisted, technology didn't merely improve—it evolved. This evolution witnessed the emergence of integrated HVAC systems, an epitome of technological advancement in the cooling domain. Beyond the mere task of cooling, these systems promised unparalleled precision in controlling temperature and humidity. Next, let's delve deeper into why integrated HVAC systems are becoming increasingly popular among cultivators.

Core Technological Features of Integrated HVAC Systems

Integrated HVAC systems have emerged as the gold standard in indoor agricultural technology, specifically tailored for specialized environments such as cannabis cultivation. These systems are not just about maintaining the right environment but are meticulously engineered to amplify every aspect of the cultivation journey, resulting in optimal yields and top-tier quality.

Automation and Intelligent Control

At the heart of automation in integrated HVAC systems lies a complex network of sensors, programmable logic controllers (PLCs), and feedback loops. These sensors continuously monitor vital environmental parameters like temperature, humidity, and CO2 levels. When any parameter deviates from the preset optimal range, the PLCs instantly activate the necessary components to rectify the situation. For example, if the temperature rises above the desired level, the dehumidifier might be activated to bring it down efficiently.

But what sets integrated HVAC systems apart is their intelligent control capabilities. By using predictive algorithms and historical data, the system can foresee potential fluctuations in environmental conditions and act before they become a problem. Over time, as the system gathers more data, its predictive accuracy improves, allowing for even more precise and proactive adjustments. This capability ensures the plants are always in their optimal growth environment.

Modularity and Scalability

Integrated HVAC systems are designed with modularity in mind to cater to the diverse needs of cultivators. Instead of a one-size-fits-all approach, these systems consist of multiple modules that can function both independently and in harmony with one another. This modular design means that components can be easily added, removed, or replaced without impacting the overall system's functionality. For example, consider Altaqua's grow room HVAC system, which embodies this principle to the letter. Some models within our range showcase a design that integrates three distinct refrigeration circuits. This advanced multi-compressor configuration facilitates scalability, modulating its performance in response to specific load demands. Given the independent operation of these circuits, a malfunction in one will not compromise the functionality of the rest, thus guaranteeing continuous service.

Scalability becomes a natural extension of this modularity. The HVAC system can adapt as cultivation spaces expand or their needs change. If a cultivator starts with a small grow room but later transitions to a larger greenhouse, they don't need an entirely new HVAC system. Instead, they can augment their existing system with additional modules, ensuring cost-effectiveness and seamless expansion. This future-proof design ensures that the integrated HVAC system remains a reliable partner throughout a cultivator's growth journey.

Comparison of Integrated HVAC Systems vs. HVAC Dry Cooler

Delving deeper into these systems and juxtaposing them provides clearer insights into their efficacy and suitability for cannabis cultivation.

Functional and Beneficial Differences

An integrated HVAC system is an all-in-one solution offering heating, ventilation, and air conditioning functionalities in a unified system. Its design aims to provide a consistently optimal environment tailored for the entirety of the cannabis growth cycle. The primary objective of hvac dry cooler is to cool and dehumidify the environment utilizing a closed-loop system. Here's a more detailed comparison:

- Temperature and Humidity Control: The integrated HVAC system provides a dual advantage, ensuring that temperature and humidity are kept within the desired range. This holistic approach ensures that plants are neither hot nor cold and receive just the right amount of moisture. Although exceptional in providing rapid cooling, the HVAC dry cooler might sometimes struggle to maintain a consistent humidity level without auxiliary equipment.

- Adaptability: One of the standout features of integrated HVAC systems is their adaptability. They can be calibrated to suit different growth stages of cannabis, ensuring each phase—from seedling to flowering—receives the right environmental conditions. The HVAC dry cooler's specialization means that while it's adept at its primary function, it might not offer the same level of adaptability without other complementary systems.

- Operational Efficiency: Both systems prioritize energy conservation, but the integrated approach of the HVAC system might edge out in certain scenarios. Managing multiple environmental factors simultaneously can optimize energy use more effectively than separate systems that might operate alongside HVAC dry coolers.

Cost and Maintenance Comparisons

When discussing systems, understanding the associated costs, both initial and ongoing, is vital.

- Initial Investment: Generally, the integrated HVAC system demands a higher initial investment due to its multifaceted capabilities. With its focused functionality, the HVAC dry cooler might be lighter on the pocket to start with.

- Running Costs: Integrated HVAC systems could offer more value over extended periods. Their ability to concurrently manage and adjust multiple environmental parameters can result in tangible energy savings. Conversely, while proficient in their core function, HVAC dry coolers may necessitate supplementary systems, possibly adding to the operational costs.

- Maintenance Perspective: Both systems necessitate regular maintenance for optimal functioning. Yet, the integrated HVAC system's integrated nature, with its multitude of functionalities, might demand more intricate maintenance. However, this complexity can also be a boon—servicing an integrated system could be simpler than addressing multiple standalone systems that one might employ with an HVAC dry cooler.

Integrated HVAC systems represent the pinnacle of cooling technology evolution, tailored specifically for cannabis cultivation. Their multifaceted capabilities, from automation to modularity, offer unparalleled precision in environmental control. Despite a potentially higher initial investment, they exhibit higher adaptability, operational efficiency, and long-term cost-effectiveness than HVAC dry coolers.

Conclusion

In the expansive realm of cannabis cultivation, understanding the nuances of cooling technology proves pivotal. The optimal growth environment hinges on precise temperature control, ensuring the right humidity levels, and making energy-efficient choices. Not only does this promote plant health, but it also aids in combating challenges like pests and diseases, which can jeopardize yields. Moreover, catering to the plants' needs during winter and ensuring the produce's quality and yield are enhanced can't be understated.

Tracing the evolution of cooling systems, we've journeyed from traditional systems like cooling towers, chillers, and condensers to more modernized solutions. Introducing HVAC dry coolers, evaporative coolers, and variable refrigerant flow systems underscores technological advances to optimize cultivation conditions. Comparing traditional cooling towers to the recent HVAC dry coolers reveals subtle differences between efficiency, energy consumption, and maintenance. These modern systems often lean towards being more environmentally conscious, notably in water conservation, while also being cognizant of the long-term cost implications.

Lastly, the emergence of integrated HVAC systems encapsulates the epitome of technological advancements in this space. Their hallmark features—like automation, modularity, and scalability—exhibit the breadth and depth of engineering ingenuity tailored for cannabis cultivation. These systems are not just about cooling but are designed for holistic environmental control, ensuring the optimal balance between temperature, humidity, and energy efficiency. When juxtaposed with standalone cooling solutions like HVAC dry coolers, it becomes clear that integrated systems bring a blend of functionality, long-term cost benefits, and ease of maintenance, making them a top choice for cultivators.

As the cannabis cultivation industry progresses, so does the need for advanced, efficient, and sustainable cooling technologies. Understanding these intricacies ensures that cultivators can make informed decisions, optimizing their yields and operational costs.

FAQ

1. What is an HVAC dry cooler?

An HVAC dry cooler is a modern cooling solution that utilizes air to dissipate heat. Dry coolers differ from other systems that depend on liquid mediums like water. Instead, they utilize surrounding air drawn across coils to dissipate heat, discharging it into the environment. This method is not only efficient but also provides a sustainable way to regulate temperatures in a range of settings.

2. How does an HVAC dry cooler differ from traditional cooling systems?

Traditional cooling systems, like cooling towers or chillers, primarily use water as their cooling medium. This process often involves evaporation, which results in water loss and requires regular refilling. On the other hand, HVAC dry coolers leverage ambient air to remove heat without water. This distinction reduces resource consumption and simplifies maintenance since there's no water treatment or risk of scaling typically associated with water-based systems.

3. Are HVAC dry coolers environmentally friendly?

Yes, HVAC dry coolers are notably eco-friendly. Their primary advantage lies in their air-based cooling mechanism, which eliminates the need for water, thereby conserving a precious resource. Furthermore, many dry coolers are designed for optimal energy efficiency, which reduces electricity consumption. This combination of water conservation and energy efficiency reduces the overall environmental footprint of cooling operations.

4. How do integrated HVAC systems compare to standalone HVAC dry coolers?

Integrated HVAC systems offer a comprehensive climate control solution, encompassing heating, ventilation, and air conditioning components. They're designed to provide a balanced environment, considering multiple parameters like temperature, humidity, and air quality. Standalone HVAC dry coolers, in contrast, primarily focus on the cooling aspect. While both systems offer efficient temperature management, integrated HVAC solutions offer a broader range of environmental controls, making them suitable for more diverse applications.

5. what financial considerations are tied to HVAC dry coolers over an extended period?

While the initial investment in an HVAC dry cooler might be higher than some traditional systems, the long-term financial implications are favorable. The operational costs are often lower due to reduced energy consumption and minimal water usage. Moreover, the maintenance expenses are often lower since there's no need for water treatment or dealing with complications like scaling and algae, common in water-based systems. Thus, over its lifecycle, an HVAC dry cooler can result in considerable savings, making it a cost-effective choice.

Share with your friends:

Popular Blogs on Altaqua:

Get HVAC Brochure?

Get HVAC Brochure?